htk4014a0600p_04

4/68

CONTENTS

1.INTRODUCTION.......................................................................................6

2.ORDER CODE..........................................................................................7

3. TECHNICAL DATA...................................................................................8

3.1.Explosion protection, ex markings, ex limit data .............................13

3.2.Accessories.....................................................................................16

3.3.Special conditions of safe use.........................................................16

3.4.Maintenance and repair ..................................................................16

4.MECHANICAL INSTALLATION.............................................................17

4.1.Handling and storage ......................................................................17

4.2.Mounting on the tank.......................................................................18

4.2.1.Installation instructions: general notes ....................................18

4.2.2.Specific installation instructions: gauge – solid applications...21

4.3.Wiring ..............................................................................................22

4.3.1.BUS (HART®) communication.................................................25

4.4.Power-on and start-up.....................................................................26

4.5.Available user interfaces.................................................................26

5.PROGRAMMING.................................................................................... 26

5.1.Programming with EView2 software............................................... 26

5.1.1.EView2 software installation and execution. .......................... 26

5.1.2.Device programming, configuration with EView2 ................... 27

5.1.3.Quick Configuration: configuration examples ......................... 37

5.2.Programming with SAP-300 display unit ........................................ 44

5.2.1.SAP-300 display unit .............................................................. 44

5.2.2.MicroTREK’s behaviour in manual programming mode ......... 45

5.2.3.Manual programming.............................................................. 46

5.3.Programming with HART® handheld (HHC) Communicator........... 47

5.3.1.Characters available for alpha-numerical data functions........ 55

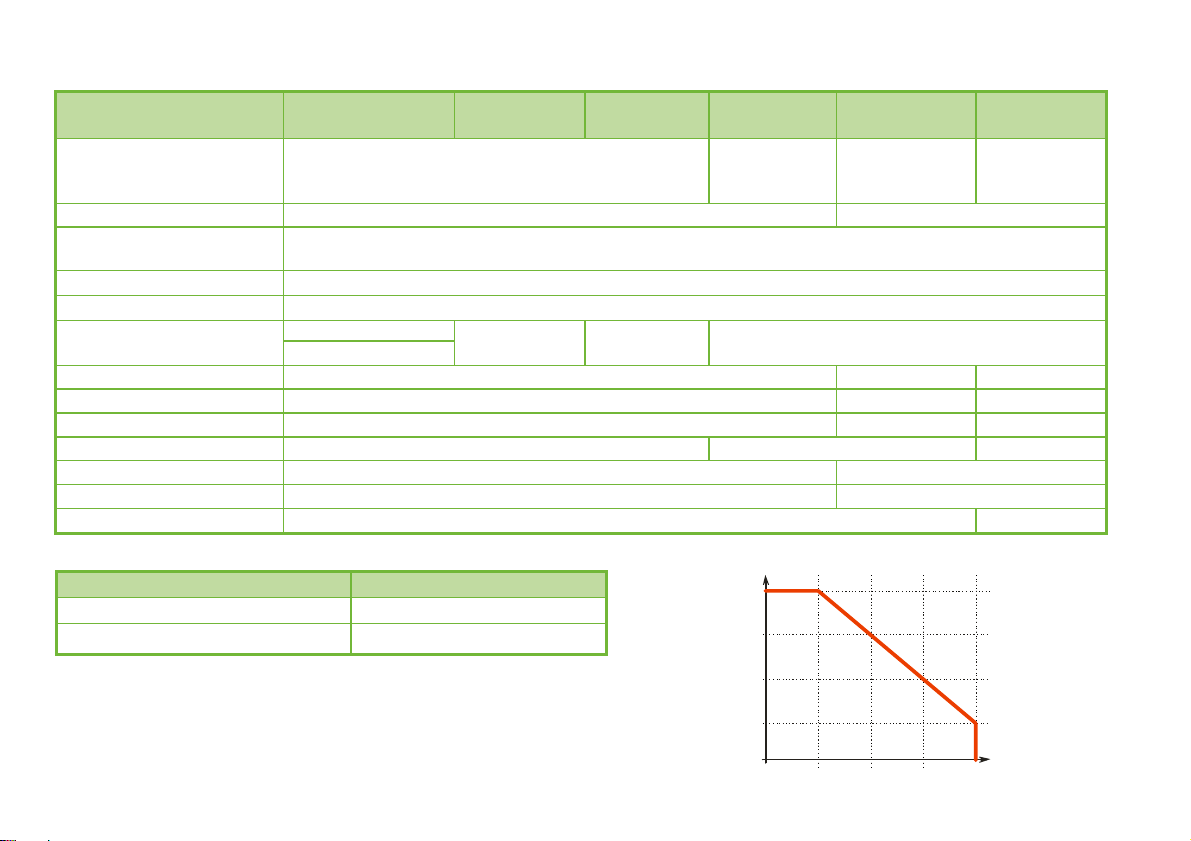

5.4.MicroTREK 2-wire T.D.R. meter characteristics............................. 55

5.4.1.Gauge operating logic when the reflection is lost ................... 57

5.4.2.Gain and voltage amplitude .................................................... 58

5.4.3.Typical signal trends ............................................................... 62

5.4.4.Automatic adjustment ............................................................. 62

5.4.5.Level measurement where there are multiple phases or layers

in the tank.......................................................................................... 64

5.5.Troubleshooting.............................................................................. 65