drcbr44a0600p_02 10 / 20

4. INSTALLATION

To enable the safe replacement of the instrument during operation the use of closing armature is recommended. A simple ball valve will be suitable for lower pressures

and for higher pressures (above 6 bar) a three-way blow-off needle-valve can be suggested.

In case of level measurement, it is advisable to screw the transmitter to the stump on the side of the tank.

Remove the packaging and protective cap just before the beginning of the assembly to avoid the damage of the diaphragm. Keep the protective cap!

In case if the installing of the unit is not immediate, the protective cap must be reinstated as soon as possible!

Treat any unprotected diaphragm with utmost care; as this part can be damaged very easily.

The device can be installed in-, or outdoors. Select the mounting position such that there is enough space for installation, programming and reading of the display.

Do not expose the device to direct sunlight when using outdoors! If you do so, direct solar radiation might cause that the permissible operating temperature of the

device would be exceeded. This is to be particularly avoided in case if the device is used in any explosion-hazardous area!

Select the operating position, so that splashed and condensed water can be drained off. Stationary liquid on sealing surfaces must be avoided! If the device has cable

outlet, the outgoing cable must be routed downwards. If the cable needed to be routed upwards, this must be done in an initially downward curve.

4.1 INSTALLATION INSTRUCTION

The measured medium – depending on its type and properties, might be hazardous to the installer. Therefore, the wear of appropriate protective clothing, gloves, and

goggles are recommended.

Torque should only be transferred to the hexagonal screw on the instrument body (torque wrench).

For the sake of noise suppression, the transmitter housing is grounded. If the grounding of the process is correct no further grounding is needed, otherwise the

instrument should be grounded.

Install the device only in depressurized and disconnected state!

Do not install the device where there is any risk of explosion. Do not open or configure the device in explosive area under normal operating conditions! For this reason,

it is recommended that the display and operating module is positioned at the same time as the mechanical installation. An important feature of the NIPRESS D-B00

family, that the individual functions can be set with the help of three miniatures, or the magnetic switches located under the metal cap. This has the advantage that the

device can be configured with the magnetic switches without opening the chambers. Right after configuration, the metal cap has to be reinstated and tightened

again, by hand!

Ensure that moisture cannot enter the device! The seals and sealing surfaces must not get dirty, as (depending on application and location) foulings might cause a

reduced degree of protection and conclusively might even lead to device failure or an irreparable damage of the device.

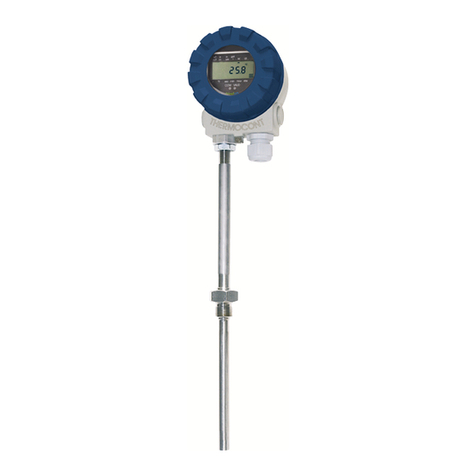

Positioning the display

The display and the operating module can be rotated continuously, to guarantee easy readability even in unusual mounting positions. The module is equipped with a

turning limiter which allows the part to be rotated by 315°.