2/36

BKI16ATEX0010X

cbr2052a0600p_05

CONTENTS

1. INTRODUCTION ........................................................................................ 4

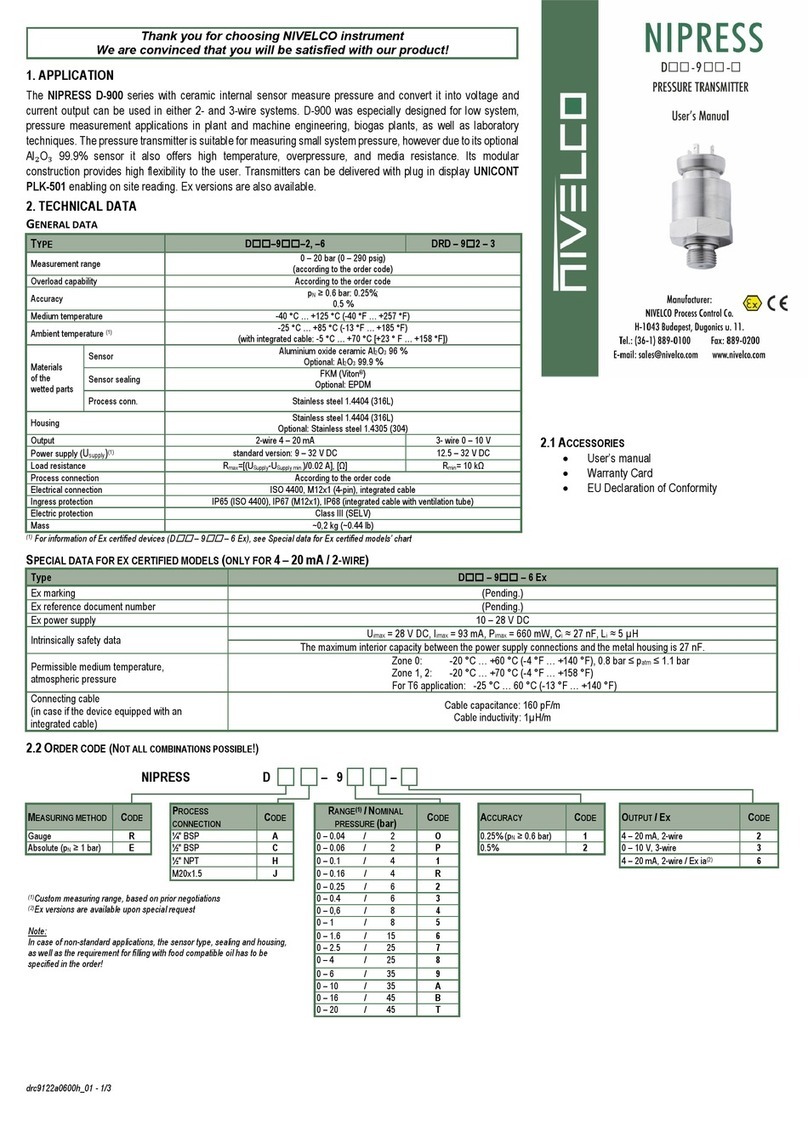

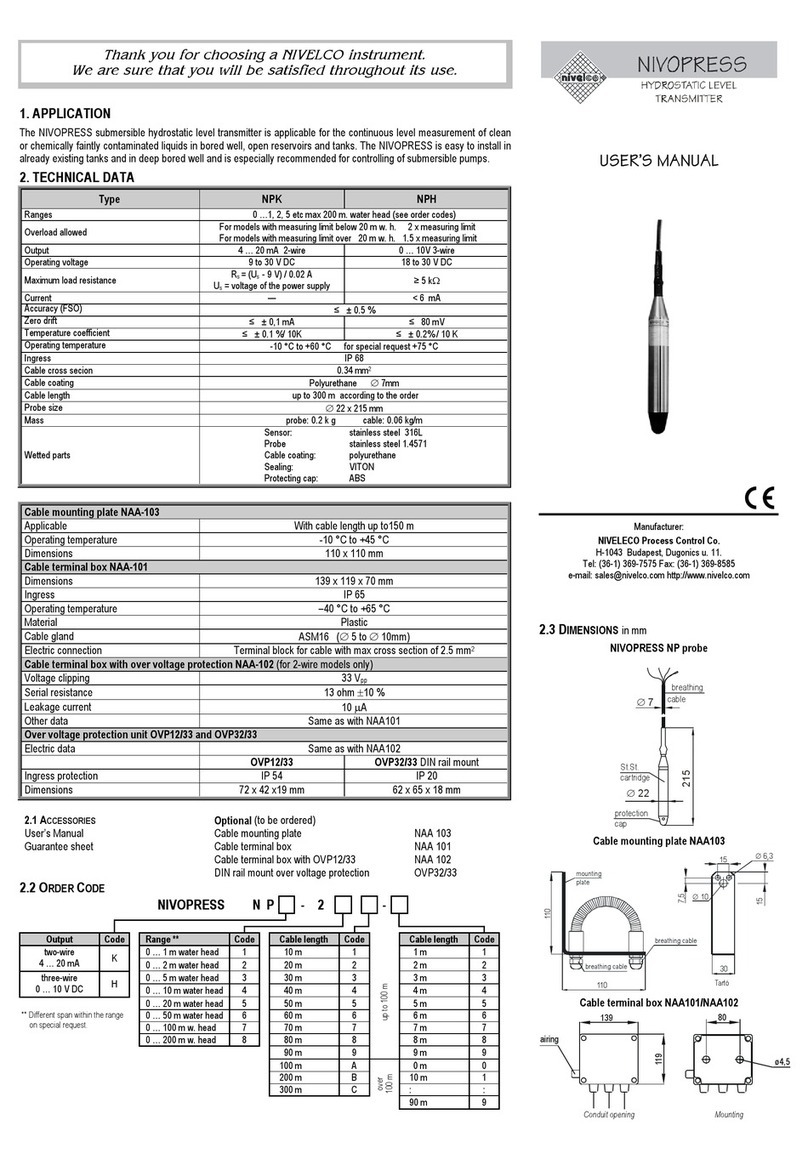

2. ORDER CODE (NOT ALL COMBINATIONS POSSIBLE!) ..................................... 5

2.1. ACCESSORIES ....................................................................................... 6

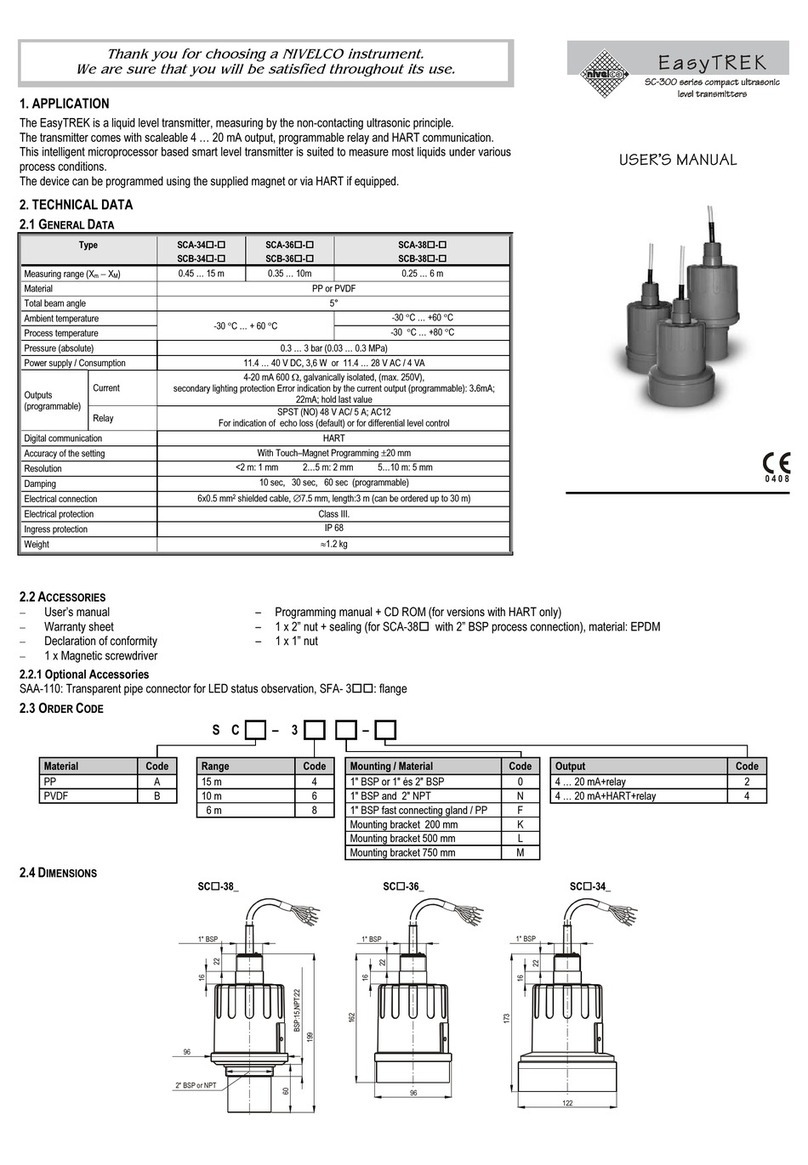

3. TECHNICAL DATA .................................................................................... 7

3.1. SPECIAL DATA FOR EX CERTIFIED MODELS............................................... 8

3.2. SPECIAL CONDITIONS FOR SAFE USE ....................................................... 8

3.3. SAP–202 DISPLAY MODULE .................................................................. 8

3.4. DIMENSIONS.......................................................................................... 9

3.5. ACCESSORIES ..................................................................................... 10

3.6. MAINTENANCE AND REPAIR .................................................................. 10

4. INSTALLATION........................................................................................ 11

4.1. MOUNTING AND WIRING ........................................................................ 11

4.2. CHECKING OF THE LOOP CURRENT ........................................................ 12

5. PROGRAMMING...................................................................................... 13

5.1. PROGRAMMING WITHOUT DISPLAY MODULE............................................ 14

5.2. PROGRAMMING WITH THE SAP–202 DISPLAY MODULE ........................... 17

5.2.1 Volume programming...............................................................................17

5.2.2 SAP–202 display module.........................................................................18

5.2.3 Steps of the programming........................................................................18

5.2.4 Indications of the SAP–202 Programming Module and the LEDs...........20

5.2.5 QUICKSET...............................................................................................21

5.2.6 Full parameter programming.................................................................... 23

6. PARAMETERS –DEFINITIONS AND PROGRAMMING.........................24

6.1. MEASUREMENT CONFIGURATION ...........................................................24

6.2. CURRENT OUTPUT................................................................................27

6.3. MEASUREMENT OPTIMALISATION...........................................................28

6.4. VOLUME MEASUREMENT .......................................................................28

6.5. 32-POINT LINEARISATION .....................................................................29

6.6. SERVICE PARAMETERS (READ ONLY) .....................................................31

6.7. TEST PARAMETERS ..............................................................................31

6.8. SIMULATION ........................................................................................32

6.9. ACCESS LOCK .....................................................................................32

7. ERROR CODES........................................................................................33

8. SUMMARY OF THE PARAMETERS........................................................35