drc9122a0600h_01 - 2/3

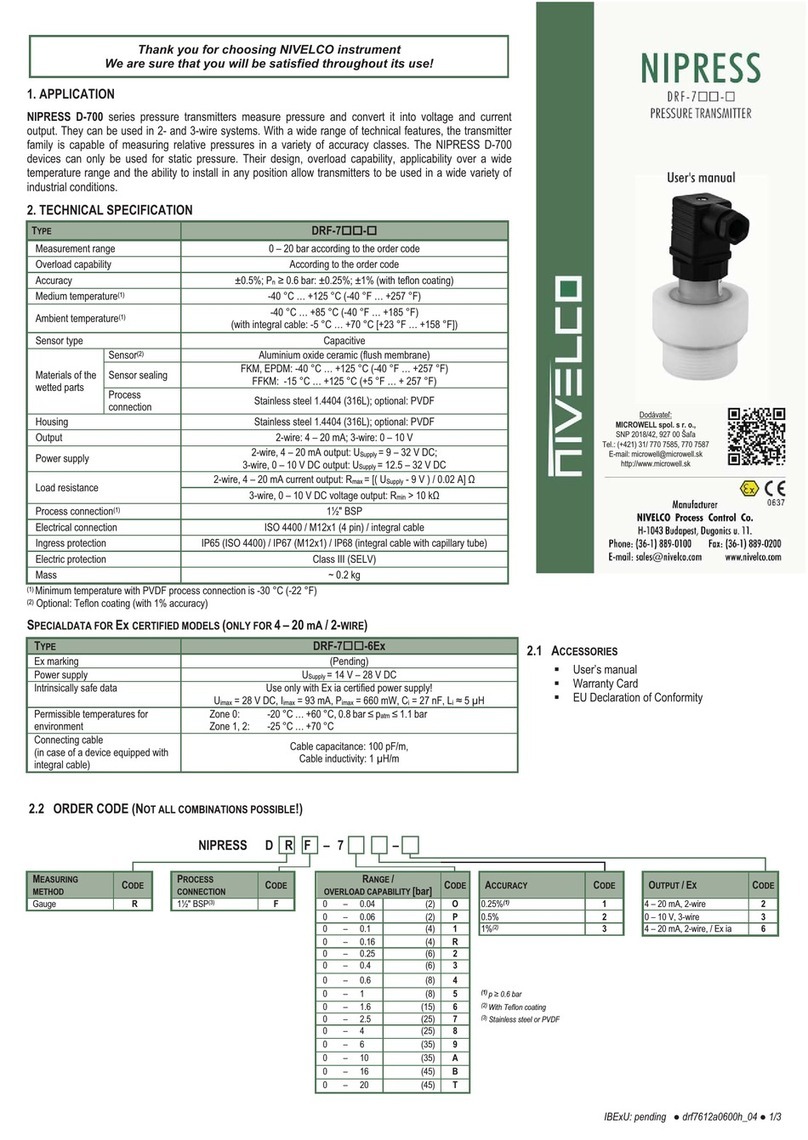

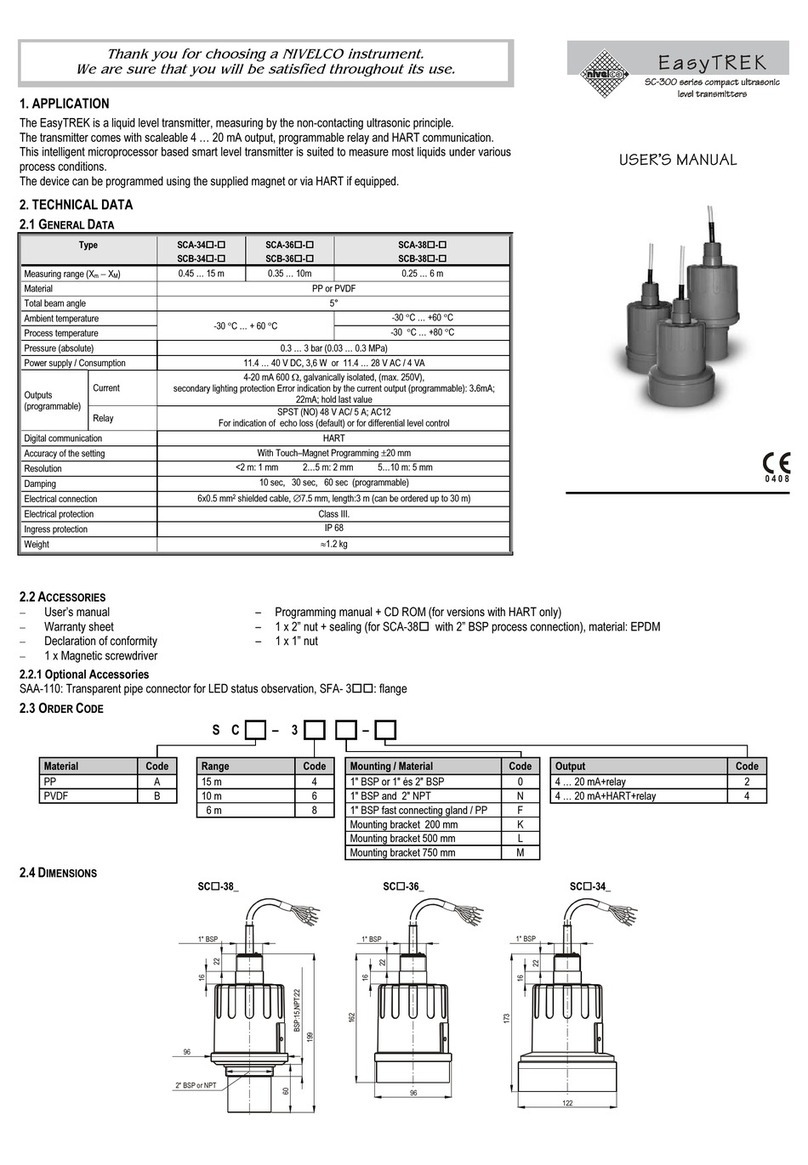

2.3 DIMENSIONS

DC–9–2 DH–9–2

Transmitter +

PLK-501-2

Plug-in display

3. INSTALLATION

Due to its small size and weight the transmitter can be directly installed on tanks,

pipes, machines, etc. without any mounting aids.

To enable the safe replacement of the instrument during operation the use of closing

armature is recommended. A simple ball valve will be suitable for lower pressures

and for higher pressures (above 6 bar) a three-way blow-off needle-valve can be

suggested.

In case of outside installation, the unit should be protected against rain or splash

water, because malfunction may occur from a leakage if the connector’s screw is

improperly tightened (i.e. not appropriate sealing).

3.1 INSTALLATION INSTRUCTION

The measured medium – depending on its type and properties, might be hazardous

to the installer. Therefore, the wear of appropriate protective clothing, gloves, and

goggles are recommended.

Be careful because the membrane is very vulnerable!

Torque should only be transferred to the hexagonal screw on the instrument body

(torque wrench). The cylindrical housing of the transmitter must not be gripped

and tightened with a pipe wrench!

The plug-in electric connector can be unplugged after releasing and removing its

fastening screw. The connection insert can be pushed out by a screw driver from

the direction of the screw. The terminal block can be rotated with 90° within the

housing, so that the orientation of the cable gland could be changed to face

downwards. This is to prevent any leakages of the housing and subsequent

damages may occur. The power cable is to be connected with the relevant points of

the connector by guiding it through the cable gland (ISO 4400). Make sure if the

cable gland and the sealing plate of the connector tightened properly! Tighten the

screw of the connector so that the sealing plate underneath seals properly!

For the sake of noise suppression, the transmitter housing is grounded. If the

grounding of the process is correct no further grounding is needed, otherwise the

instrument should be grounded.

When installing the device, avoid high mechanical stresses on the pressure port!

This is particularly true for the pressure port made of plastic.

Installation steps:

Tightening torques:

¼" BSP: max. 5 Nm;

½" BSP: max. 10 Nm;

¼" NPT: max. 30 Nm;

The specified tightening torques must not be exceeded!

Mounting steps for BSP thread connections according to DIN 3852:

Do not use any additional sealing material such as Teflon tape! Check if the O-ring

is undamaged, it has a flawless and clean surface and seats in the designated

groove properly. Screw the device into the corresponding thread by hand, and

tighten the parts with a suitable torque wrench.

Mounting steps for NPT thread connections:

Use a suitable sealant (e.g. PTFE tape). Turn the device by hand to the correct

thread and tighten it with an open-end torque wrench.

If your device can be secured with a knurled ring, the pressure transmitter should

only be tightened by hand!

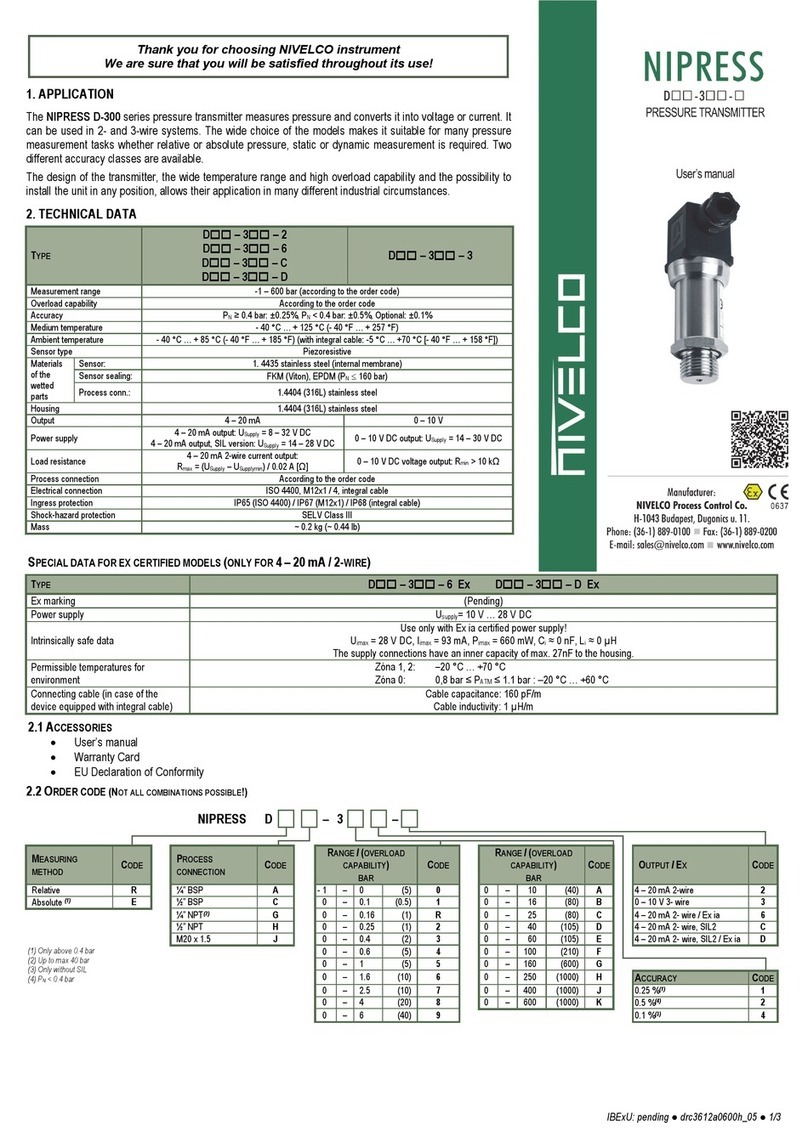

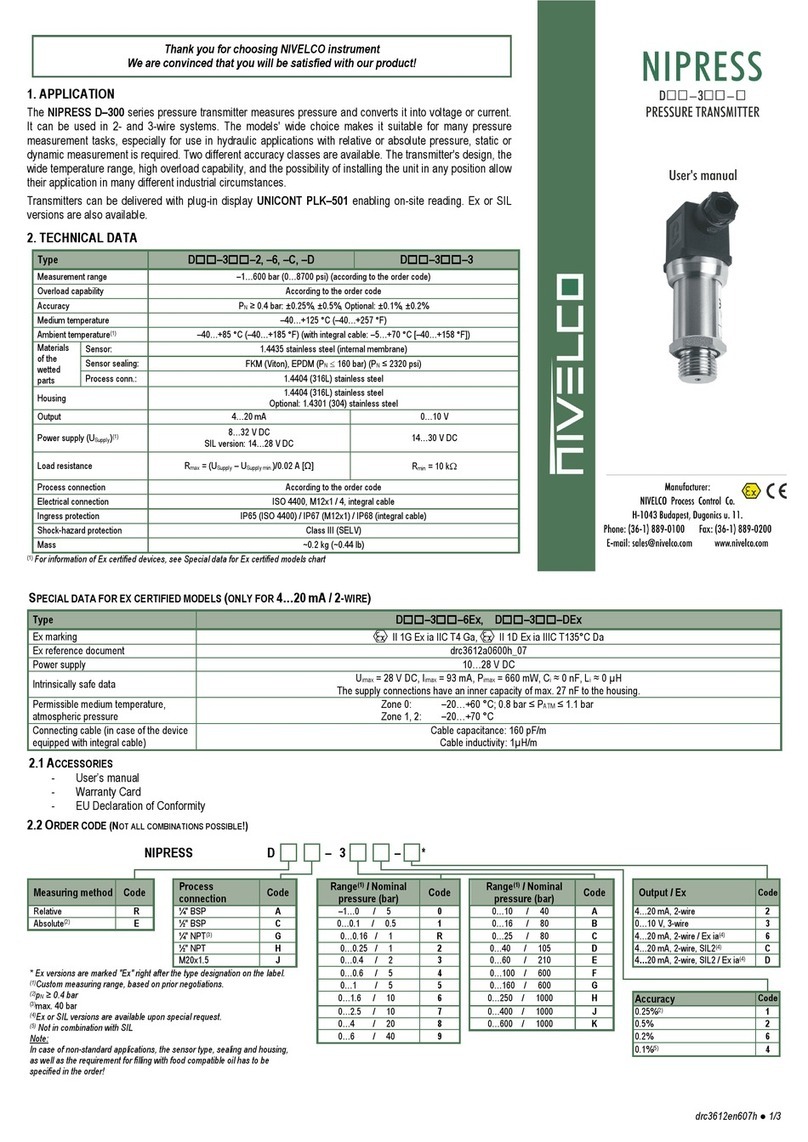

4. WIRING

Use a shielded and twisted multicore cable for the electrical connection. Electrically

connect the device according to the “Connection of ISO 4400 plug” figure. For

devices with cable gland, make sure that the external diameter of the cable used is

within the allowed clamping range! Once connected the wires, tighten the gland

screw firmly until the sealing is proper!

For the installation of a device with an integrated cable, the bending radiuses have

to comply with the following:

Cable without ventilation tube:

- static installation: 8-fold cable diameter,

- dynamic application: 12-fold cable diameter.

Cable with ventilation tube:

- static installation: 10-fold cable diameter,

- dynamic application: 20-fold cable diameter.

In case of devices with cable outlet and integrated ventilation tube, the PTFE filter

located at the cable end on the ventilation tube must not be damaged or missing!

2-wire current output

3-wire voltage output

Connection of integrated cable

Connection of iso 4400 plug

Connection of M12x1 / 4 pin plug