BKI16ATEX0014X

dbf5512a0600p_05

4 / 20

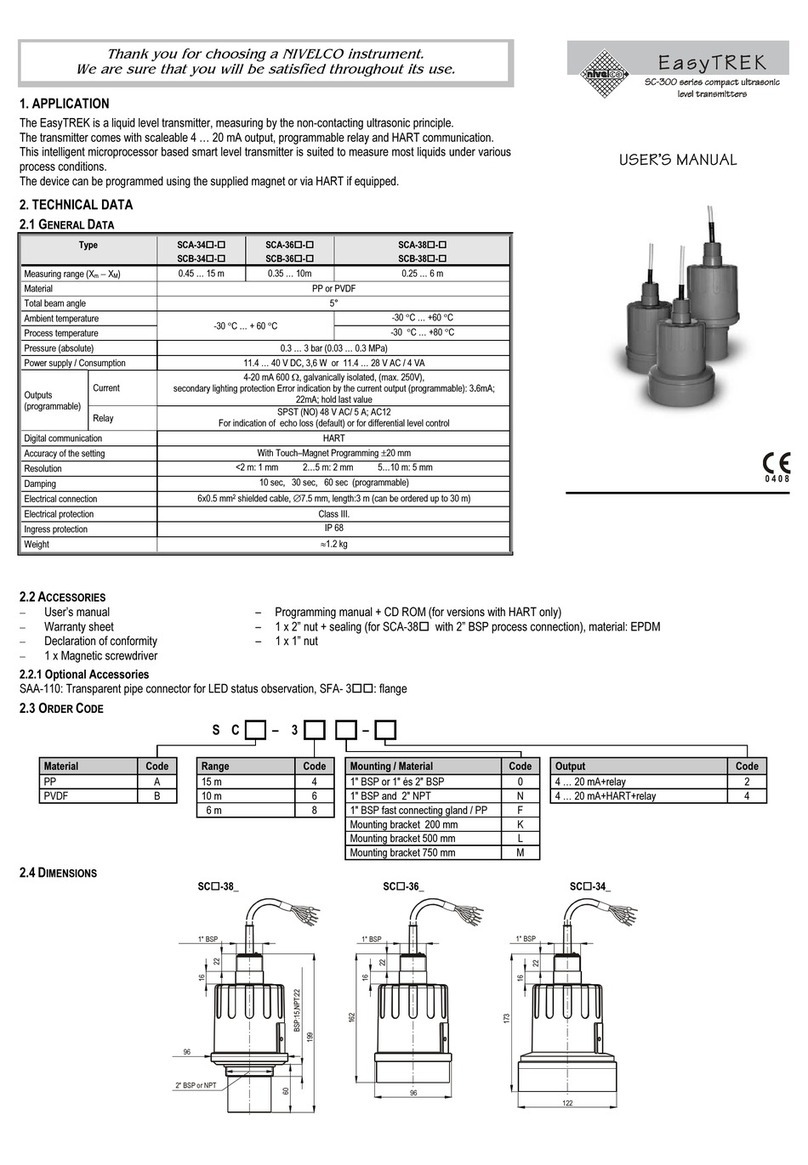

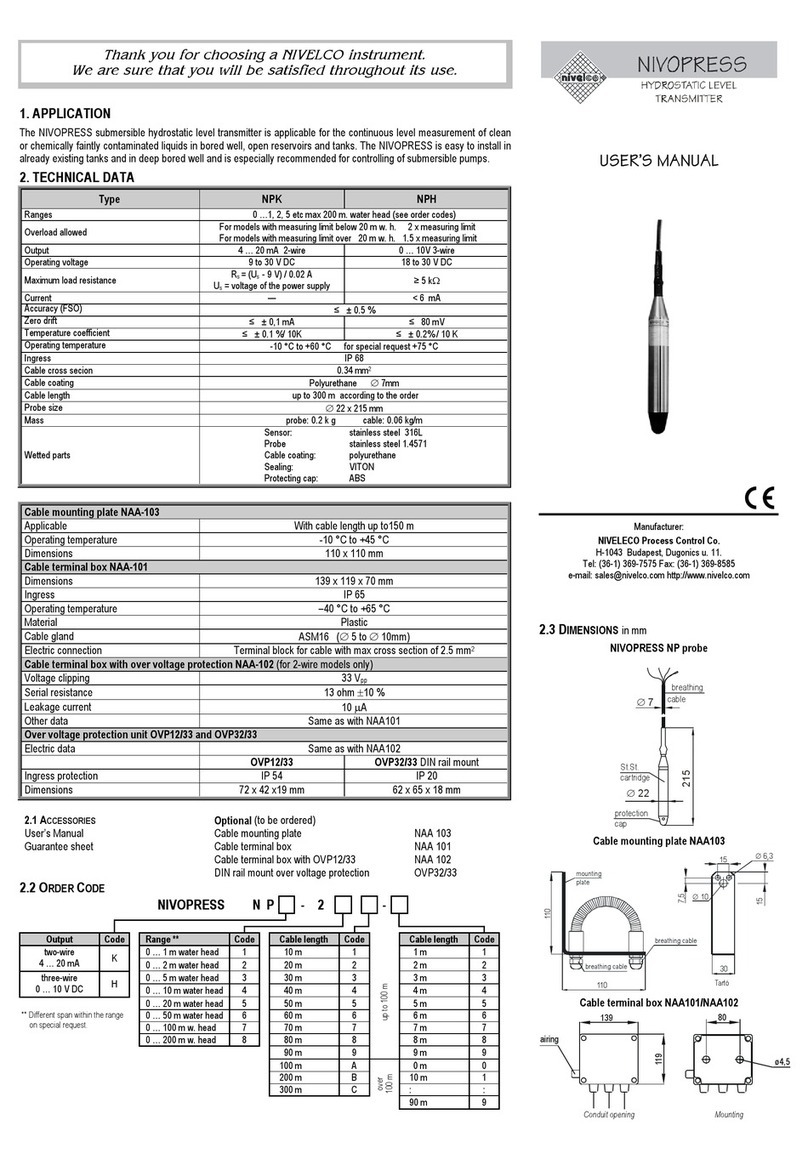

CONTENTS

1 INTRODUCTION.....................................................................................................................................................................................................................5

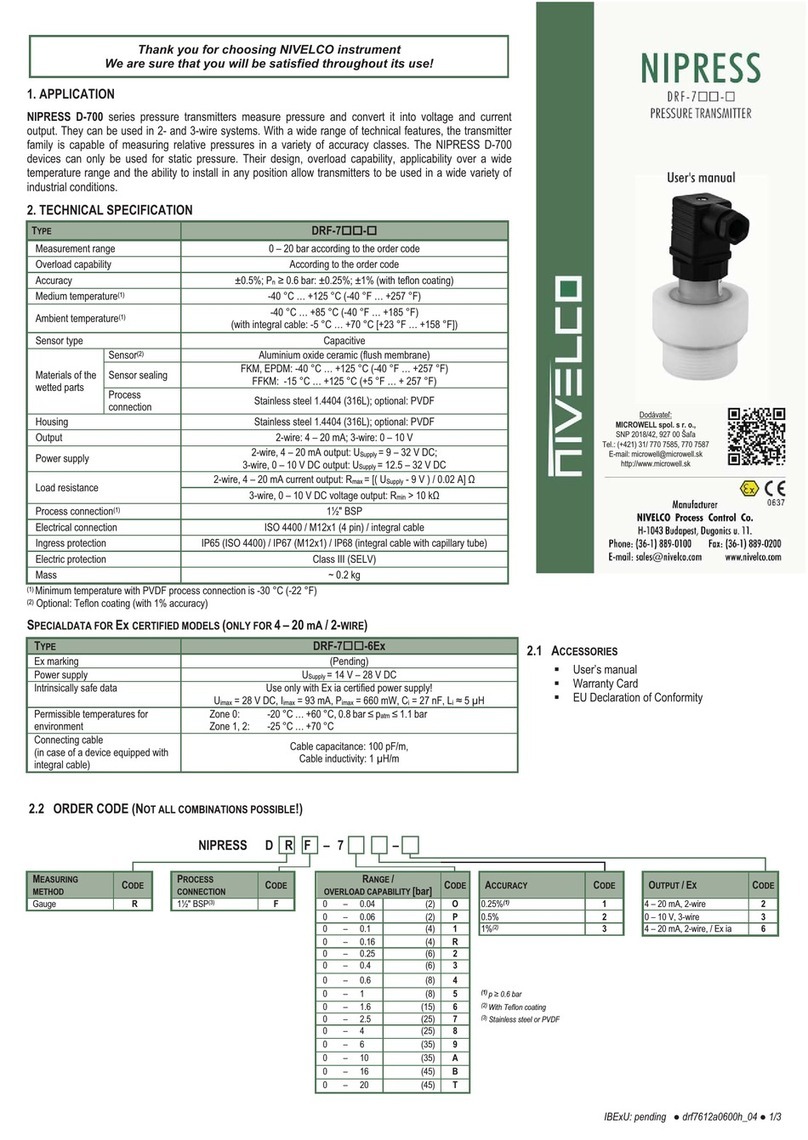

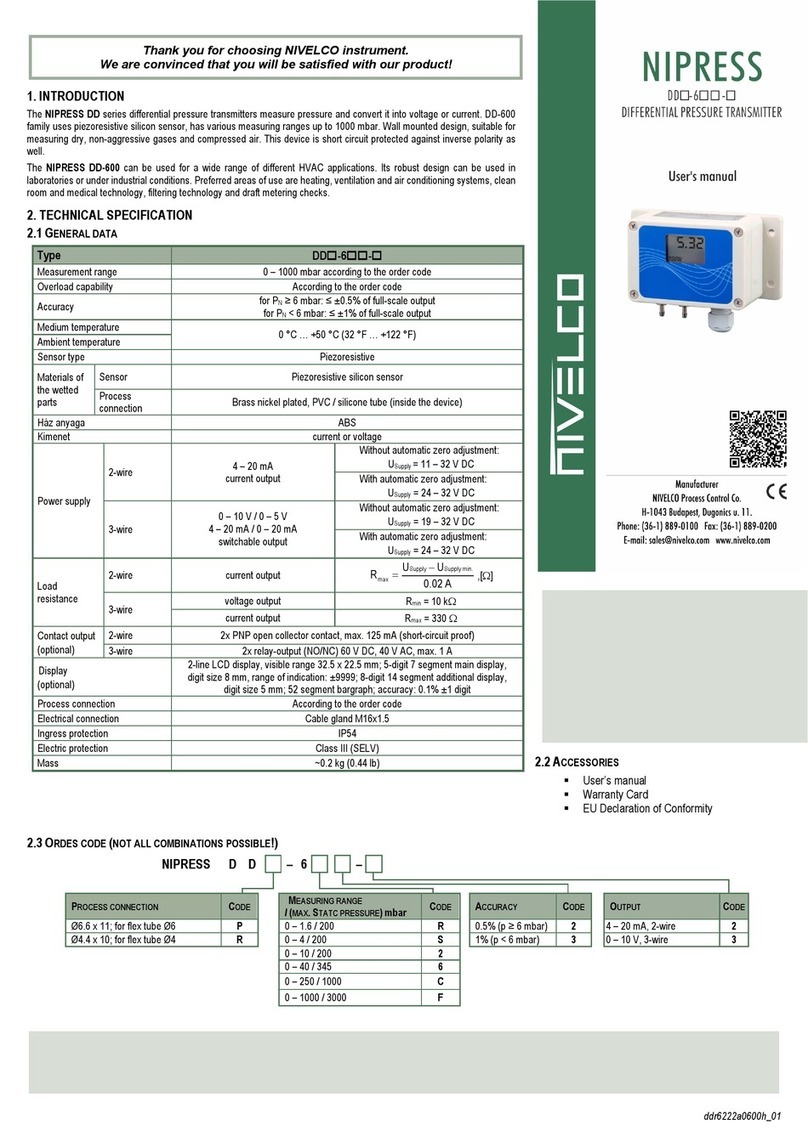

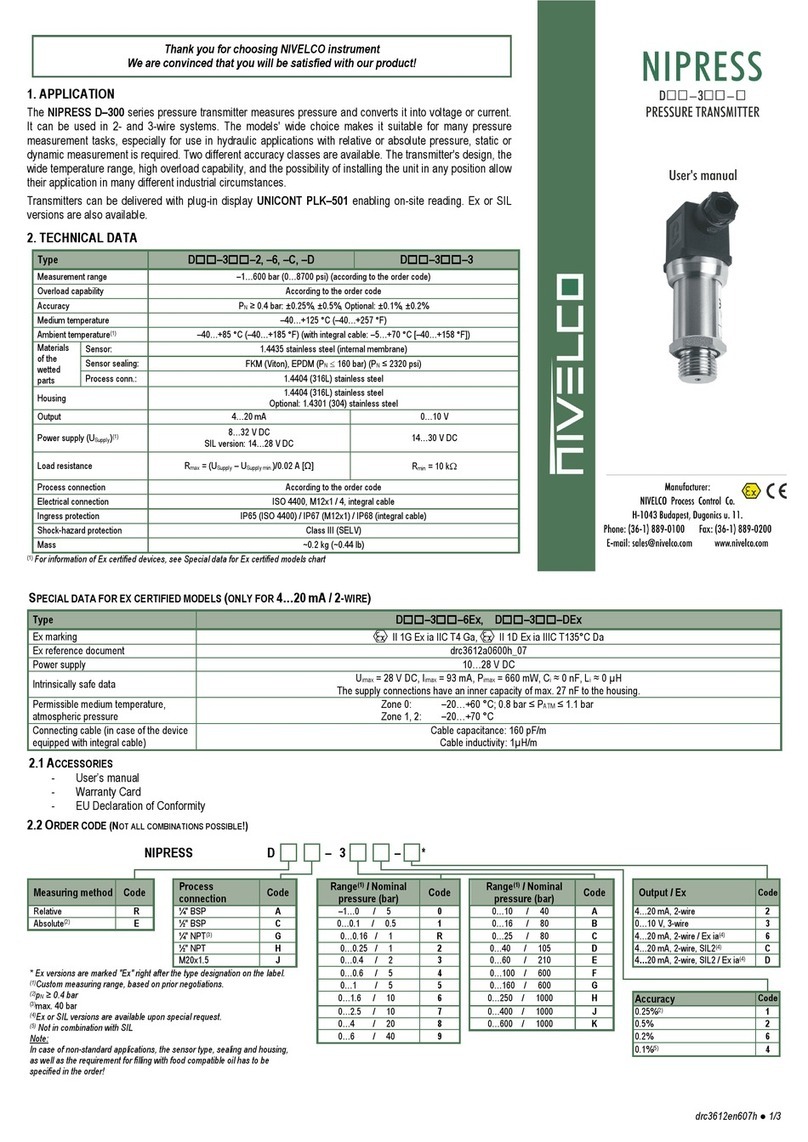

2 ORDER CODES......................................................................................................................................................................................................................5

3 TECHNICAL DATA.................................................................................................................................................................................................................6

3.1 GENERAL DATA ...................................................................................................................................................................................................................6

3.2 DIMENSIONS .......................................................................................................................................................................................................................8

3.3 ACCESSORIES.....................................................................................................................................................................................................................8

4 INSTALLATION AND ELECTRIC CONNECTION.................................................................................................................................................................9

4.1 WIRING............................................................................................................................................................................................................................ 10

4.2 SAFETY REGULATIONS FOR THE EEX IA APPROVED UNITS..................................................................................................................................................... 10

5 PUTTING INTO OPERATION, PROGRAMMING ............................................................................................................................................................... 11

5.1 PROGRAMMING ................................................................................................................................................................................................................ 12

5.1.1 DISPLAY AND KEYS OF THE SAP 203 DISPLAY MODULE................................................................................................................................................. 13

5.1.2 STEPS OF PROGRAMMING........................................................................................................................................................................................... 14

5.1.3 PARAMETERS –DESCRIPTIONS AND PROGRAMMING...................................................................................................................................................... 15

5.2 ERROR CODES.................................................................................................................................................................................................................. 19

5.3 HART COMMUNICATION.................................................................................................................................................................................................... 19

6 MAINTENANCE AND REPAIR ........................................................................................................................................................................................... 19

7 STORAGE............................................................................................................................................................................................................................ 19

8 WARRANTY..............................................................................................................................................................HIBA! A KÖNYVJELZŐNEM LÉTEZIK.