Nivetec Thermo Scientific AquaSensors AquaClear AQT... User manual

Thermo Scientific AquaSensors™

AquaClear™Low Range

Turbidimeter

User Guide

ROSS and the COIL trade dress are trademarks of Thermo Fisher Scientific Inc. U.S. patent 6,793,787.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, PerpHecTion, pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink,

ROSS, ROSS Ultra, Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ,

AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental Product

Authority, Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode, Minimum Stir

Requirement, MSR, NISS, One-Touch, One-Touch Calibration, One-Touch Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture

Pentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB, SMART AVERAGING, Smart CheK, SMART STABILITY,

Stacked, Star Navigator 21, Stat Face, The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are trademarks of

Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

PerpHecT meters are protected by U.S. patent 6,168,707.

PerpHecT ROSS electrodes are protected by U.S. patent 6,168,707.

ORION Series A meters and 900A printer are protected by U.S. patents 5,198,093, D334,208 and D346,753.

ionplus electrodes and Optimum Results solutions are protected by U.S. patent 5,830,338.

ROSS Ultra electrodes are protected by U.S. patent 6,793,787.

ORP standard is protected by U.S. patent 6,350,367.

No Cal electrodes are protected by U.S. patent 7,276,142.

© 2009 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

The specifications, descriptions, drawings, ordering information and part numbers within this document are subject to change without notice.

This publication supersedes all previous publications on this subject.

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 1

Preface

This instruction manual serves to explain the use of the Thermo Scientific AquaSensors AquaClear Turbidity

System and is written to cover as many applications as possible. Please do nothesitate to contactThermo

Fisher Scientific or an authorized representative with questions or concerns.

The information presented in this instruction manual is subject to change withoutnotice as improvements are

made, and does notrepresent any commitment whatsoever on the partof Thermo Fisher Scientific.

Thermo Fisher Scientific cannotacceptany responsibility for damage or malfunction ofthe equipment due to

improper use.

Contact Information

To contactThermo Scientific AquaSensors Technical Support:

Within the United States call 1.800.225.1480 or fax 978-232-6015.

Outside the United States call 978.232.6000 or fax 978.232.6031.

In Europe, the Middle East and Africa,contact your localauthorized dealer.

Visitus on the web at www.thermo.com/processwater

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 2

Safety Information

The AquaClear Turbidity System shall be installed and operated only

in the manner specified. Only a skilled, trained or authorized person

should carry out installation, setup and operation of the sensor

system.

Before using the system, make sure that is connected as specified.

Failure to do so may result in permanent damage to the system of its

components.

Protection against electric shock will be achieved only by observance

of the corresponding installation rules.

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 3

TABLE OF CONTENTS

1. INTRODUCTION..........................................................................................................................4

1.1. GENERAL INFORMATION................................................................................................................4

1.2. INTENDED USE...............................................................................................................................5

2. PRODUCT DESCRIPTION..........................................................................................................6

3. MOUNTING, WIRING AND PLUMBING..................................................................................7

3.1. MOUNTING ...................................................................................................................................7

3.2. PLUMBING ....................................................................................................................................8

3.3. WIRING AND 24 VDC POWER........................................................................................................9

3.4. SAMPLE CHAMBER DETAILS........................................................................................................ 11

4. MEASURE SCREEN OVERVIEW............................................................................................ 12

5. MENU STRUCTURE..................................................................................................................13

6. CALIBRATION...........................................................................................................................17

6.1. SPAN CALIBRATION..................................................................................................................... 17

6.2. ZERO CALIBRATION .................................................................................................................... 20

6.3. TEMPERATURE CALIBRATION ......................................................................................................22

7. CONFIGURATION..................................................................................................................... 25

8. DATASTICK COMMS MENU...................................................................................................27

8.1. SETTING DATASTICK STATION NUMBER ......................................................................................27

8.2. SETTING DATA TYPE ................................................................................................................... 28

8.3. SETTING DATASTICK BAUD RATE ............................................................................................... 29

8.4. SETTING DATASTICK PARITY ...................................................................................................... 29

9. ANALOG OUTPUT(S)................................................................................................................ 30

10. RELAY (OPTION) ......................................................................................................................34

11. HELP MENU ...............................................................................................................................35

12. RESET AV38................................................................................................................................36

13. PERFORMANCE SPECIFICATION.........................................................................................37

14. TURBIDITY SYSTEM ORDER MATRIX AND ACCESSORIES...........................................39

15. LIMITED WARRANTY ............................................................................................................. 41

16. TERMS AND CONDITIONS...................................................................................................... 42

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 4

1. INTRODUCTION

1.1. General Information

Thank you for purchasing the AquaClear Drinking Water Turbidimeter.

The product is designedfor continuous use in industrialprocess applications and complies with safety

regulations currently in force. Improper use could lead to hazards for the user or a third-party, and/or adverse

effects to the plant or other equipment.

Thermo Fisher Scientific does not accept any liability for damage that may arise if information in this

manual is not followed. Therefore, the operating instructions and specifications must be read and

understood by all persons involved in installation and operation of this equipment.

This manualidentifies safety instructions and additional information by means of the followingsymbols:

This symbol draws attention to safety instructions and warnings of potential danger,

which if neglected,could result in injury to persons and/or damage to property.

This symbol identifies additional information and instructions, which if neglected, could

lead to inefficient operation and possible loss of production.

Itis recommended that this manual be made accessibleto everyone who may need it as a reference.

Please contactThermo Fisher Scientific or an authorized representative with any questions.

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 5

1.2. Intended use

The AquaClear Turbidity Systemis used for continuous monitoring of low-range turbidity in drinking water

applications. The systemalso measures water temperature.

Data is reported through a local display and a scalable 4-20 milliamp current output. Options include a

second current output, up to 2 configurable relays and one ofseveral digital protocols for remote monitoring,

calibration, configuration and diagnostics.

Any other use,or use not mentioned here, that is incompatible with the technical specifications is deemed

inappropriate. The operator is solely responsible for any damage arising from such use.

Other prerequisites for appropriate use include:

•Observing the instructions,notes and requirements setout in this instruction manual.

•Observing all local safety regulations.

•Observing all warnings and cautions in the documentation regarding all products used in this

measurementsystem, including the sensor,mounting hardware, AV38 electronics and cabling.

•Observing the prescribed environmental and operationalconditions.

•Observing chemical compatibility with all wetted materials.

1.3. Safety Instructions

The Turbidity System should be installed and operated only by personnel familiar with

the sensor and qualified for such work.

A defective Turbidity System should be returned to Thermo Fisher Scientific for repair

or replacement. Contact Thermo Fisher Scientific to obtain a Return Material

Authorization (RMA) number.

No modifications to the Turbidity System are allowed. The manufacturer/supplier

accepts no responsibility for damage caused by unauthorized modifications. The risk

is borne entirely by theuser.

1.4. Removalfrom Service / Correct Disposalof the Turbidity System

Removal from Service

•Disconnect the cable wiring from the controller terminalblock.

•Remove the Turbidity Systemfrom the mounting hardware.

Correct Disposalof Unit

•When the Turbidity Systemis taken out of service, observe the local environmentalregulations for

correctdisposal.

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 6

2. PRODUCT DESCRIPTION

The AquaClear Turbidity Systemis used for continuous monitoring of low-range turbidity in drinking water

applications. The systemalso measures water temperature.

In the standard system configuration,data is reported through a local display and a scalable 4-20 milliamp

currentoutput. Options include a second current output,up to 2 configurable relays and one of severaldigital

protocols for remote monitoring, calibration,configuration and diagnostics. All functions can be accessed

through a digitalnetwork with or without a localdisplay interface.

The AquaClear Turbidity System uses a pre-calibrated optical detector mounted in a sample chamber

specifically designed to prepare water for low-range turbidity measurements. A collimated white light in the

chamber lid is used to illuminate particles suspended in the water.

The chamber removes bubbles from the water so that solid particles can be accurately detected. The

chamber lamp will provide collimated white light for up to two years and is easily changed from the top.

Because the chamber volume is only 135 milliliters, it takes a very small amount of Formazin to perform EPA

mandated calibrations.

Highlights:

Meets USEPA Method 180.1

Pre-calibrated Measurement

Plug and Play Optical Detector

135 ml Sample Chamber

0.001 NTU Resolution

FastResponse

2 year light source

Compact mounting footprint

Digital Networking Interface

Local Interface with currentloops and relays

Low flow rate

Temperature measurementincluded

Plugand Play IndustrialCommunications Adapters

The AquaClear Drinking Water Turbidity systemis part of the DataStick family of products. The DataStick can

be used with any sensor head manufactured by Thermo Fisher Scientific and can communicate directly with

industrial computer systems using any of the communications adapters offered. The Thermo Scientific

AquaSensors AV38 local display is provided as standard equipment for the Turbidity System. It is however

not required and any number of turbidity systems can be digitally networked to a single computer interface.

Open protocol commands for calibration, configuration, diagnostics and measurement are available (consult

the desired communications manual).

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 7

3. Mounting, Wiring and Plumbing

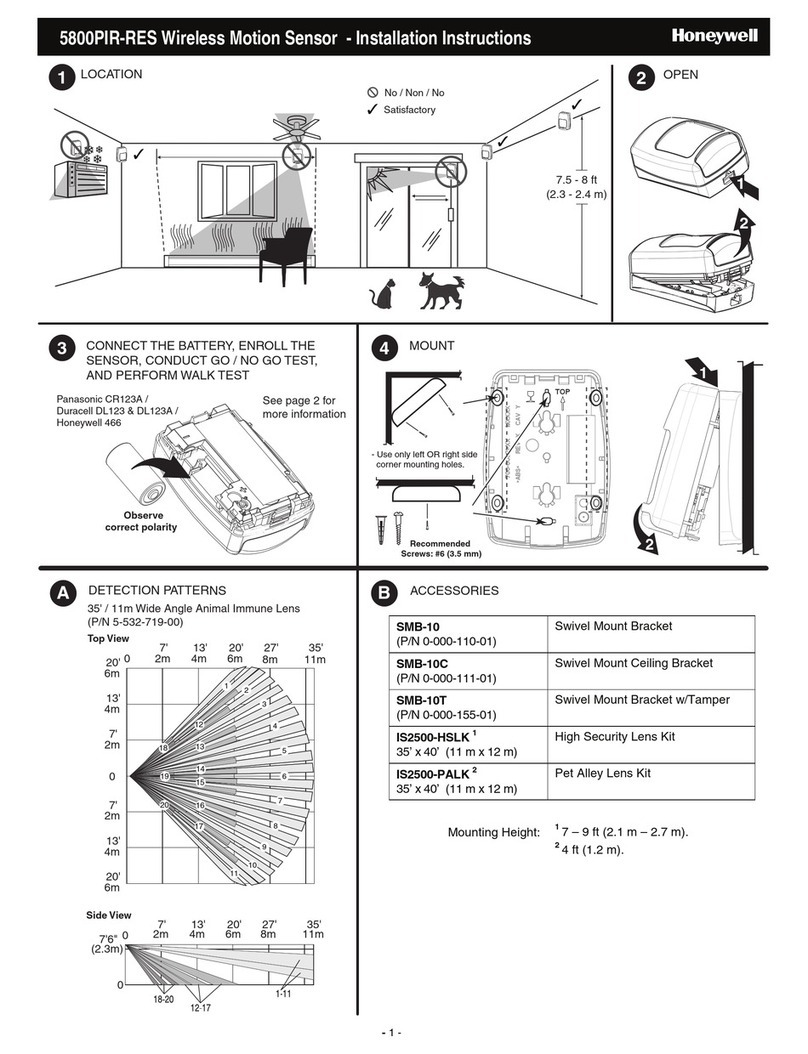

3.1. Mounting

The Drinking Water Turbidity Systemis mounted on a 12 inch x 12 inch panel with four inch mounting

holes. Use inch bolts with washers to mount the panel to a wall. Make sure the sample chamber is level

and plumb to insure proper water levels are maintained in the sample chamber. Itis important to note that

the system mustbe fixed securely to the wallto insure the chamber does not move when handled or touched.

Figure 2.1: Wall mounting clearances

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 8

Mounting tools and equipment:

inch Drill with drill bit for appropriate wall anchor.

Four diameter bolts – 1.5 inches long.

Four inch ID flat washers

Wrench to turn bolts

Level to insure the systemis level when mounted

General Mounting Instructions:

1. Place the 12x12 inch panelon the wallwhere it is to be mounted and mark the placement ofthe upper

lefthole.

2. Drill a mounting hole for the upper leftcorner with a masonry drill bit.

3. Mountthe turbidity system with the upper leftbolt.

4. Using a level, rotate the systemuntil level,then mark the other three mounting holes.

5. Rotate the turbidity system out of the way and drill the other three mounting holes.

6. Place allfour bolts with washers and tighten. Use shims if necessary to insure the sample chamber is

level.

3.2. Plumbing

The Drinking Water Turbidity System has an INLET,an OUTLET and a DRAIN.

Barb fittings are provided for the INLET and OUTLET in the event that 3/8 inch ID tubing is used.

When piping is used instead oftubing, remove the barb fittings to install inch NPT threaded pipe for the

INLET,OUTLET and DRAIN.

OUTLET and DRAIN Plumbing Recommendations: Use straight inch NPT threaded pipe thatextends to a

vented drain. Pipe restrictions that result in back pressure for OUTLET and DRAIN are not allowed.

INLET Plumbing Recommendations: Use 3/8 ID tube or inch NPT threaded pipe from sample source.

Flow rate must be between 250 to 750 ml/min (4 to 12 gph). If the source is under pressure,use an

appropriate flow or pressure valve to obtain consistent flow. The turbidity sample chamber has an overflow

weir thatmust not be restricted.

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 9

3.3. Wiring and 24 VDC Power

Access to allUser wiring is through the DIN junction box in the lower lefton the mounting panel.

The standard Turbidity systemrequires 24 volt DC power and typically draws 270 mA (6.5 watts). Most of the

currentis drawn by the tungsten bulb and the AV38 backlight.

Line powered versions of the Turbidity system are also available.

Pg11 and Pg16 punch out conduit holes are provided for user terminal connections. We supply Pg11 cord

grips thatcan be removed.

Turbidit

y

User

Junction

Box

Lamp assembly

screws in to sample

chamber lid

Lamp cable connection

Terminal Connections to AV38

USER Terminal Connections: See

next page for wiring tables

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 10

USER WIRING FOR: 1 Current Loop without Host Communications

Terminal Wiring

1 24VDC from Power Supply

2 Ground from Power Supply

3

4

5 Earth Ground from Power Supply

6 CurrentLoop -

7 CurrentLoop +

8

9

10

11

12

Note:Current Loop Requires 24 VDC supply. Options for second current loop and relays are available.

USER WIRING FOR: Digital Communications to Host Computer with 2 Outputs and Relay

Terminal Wiring

1 Red wire from Host Network (+24 VDC)

2 BLACK wire from Host Network (Network Ground)

3 White wire fromHost Network

4 Blue wire from HostNetwork

5 Shield wire from Host Network

6 OUTPUT 1 (-)

7 OUTPUT 1 (+)

8 OUTPUT 2 (-)

9 OUTPUT 2 (+)

10 Relay – Normally Open Terminal

11 Relay – Common Terminal

12 Relay – Normally Closed Terminal

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 11

3.4. Sample Chamber Details

The Drinking Water Turbidity sample chamber is designed for easy access and maintenance.

The chamber lid is lifted to gain access to the sample chamber. Set it on top of the AV38 during chamber

maintenance. When replacing the lid, it should be aligned using the exterior alignmentmarkers on the front

edge of the chamber and the lid.

The alignmentpeg on the

Sample Chamber mustline

up with the alignment hole in

the lid.

Sample Chamber Lid

with integral lamp assembly

Sample Chamber

with bubble trap

Keep aperture dry

Exterior marker to align lid with

sample chamber

Sample Chamber

Bubble Trap

Sample Chamber

with Lid in Place

Alignment Peg

Alignment hole

DataStick with

Optical Sensor

Head can be

removed and

replaced

Chamber Lid with Lamp

Chamber Body

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 12

Figure 3.2: The measure screen when the Sensor

Head is absent.

4. MEASURE SCREEN OVERVIEW

The AV38 user interface is shown in Figure 3.1. It consists of an LCD module that contains two lines of 16

alphanumeric characters and seven keys to navigate the menu. The contrast of the LCD module can be

adjusted by simultaneously pressing the escape and up-arrow keys (for more contrast) or the escape and

down-arrow keys (for less contrast).

When the DataStick and communications adapter are connected to the AV38 display but the optical sensor

head is absent, the measure screen indicates the fault as shown in Figure 3.2.

Sensor Head

Absent

MENU ESC

ENTER

Lamp Assembly

The lamp assembly screws into

the lid. The cable is routed to the

user terminal box.

Lamp with cable

Chamber Lid

0.035 NTU AB

30.8 °C DS1: 6

MENU ESC

ENTER

Figure 3.1: The elements of the measure screen

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 13

Figure 3.2: The measure screen when the

DataStick is absent.

Table 4.1: AV38 Main Menu Functions

When the DataStick or communications adapter are not connected to the AV38 display, the measure screen

indicates the faultas shown in Figure 3.2.

Refer to the AV38 Manual for detailed information on User Interface operation.

5. MENU STRUCTURE

Pressing the menu key while a measure screen is displayed accesses the main menu. The items in the main

menu are the sameregardless of the type of sensor head that is installed in the DataStick. Table 4.1 shows all

accessible functions including optional features.

Main Menu Option Function

Calibrate

(Station Number)

Sensor calibration choices are automatically available for installed sensor head.

Enter the MENU from the measure display of interest – station in lower right.

Configure

(Station Number)

Configuration choices are automatically available for the installed sensor head.

Enter the MENU from the measure display of interest – station in lower right.

DataStick Comms Set the station address, baud rate and parity for the Modbus DataStick of

interest.

Chlorine Configure Select total, HOCL or OCL- concentration for output. Select pH compensation –

manual set or active measure. (Only when Chlorine DataStick Present).

Hold Outputs Holds the 4-20 mA and Relay outputs

Analog Output 1 Set 4 mA and 20 mA values. Calibrate and test the current output with a meter.

Analog Output 2 (option) Set 4 mA and 20 mA values. Calibrate and test the current output with a meter.

PID Controller Set up PID control functions for analog outputs. Available with pH or

Conductivity.

Relay A (option) Set timer, alarm, or control functions. (Optional)

Relay B (option) Set timer, alarm, or control functions. (Optional)

Help Indicates AV38 software version

Reset AV38 Resets AV38 configuration to default current output, relay and PID settings.

Exit Returns to the measure screen

DataStick

Absent

MENU

ESC

ENTER

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 14

The main menu is navigated using the up/down arrows to display a desired function.The () symbol is used to

indicate main menu choices.

To select a menu choice, press the ENTER key when the desired choice is displayed.

To return to the measure screen, press the ESC key.

When ever there is a value to be entered or a choice to be made, the second line of the display will be

surrounded by parentheses (()). The name of the value being entered or choice being made will appear on

the upper line of the screen and be appended with a question mark (?) to indicate that the user is to provide

input. Figure 4.1 shows the list of standard menu choices and optional menu choices in the context of the

AV38 display presentation.

Figure 4.1: The main menu (standard and optional feature lists)

To illustrate navigation through the main menu the following sequence of down arrow key presses is shown.

The up arrow can always be used to scroll up through the list.

A pressedkey is identified by a gray background, e.g., .

From the measure screen, press MENU to display the list of options. Generally, Calibration will be the first

option. To select a calibration function, press ENTER. Press the down arrow to scroll through the list. Press

ESC to return to the measure screen.

Main Menu

Calibrate

MENU

ESC

ENTER

Configure

DataStick Comms

Analog Output

Help

Reset AV38

Exit

Main Menu

Standard

ESC

Main Menu

Calibrate

MENU

ESC

ENTER

Configure

DataStick Comms

Analog Output 1

Analog Output 2

Relay A

Relay B

Help

Reset AV38

Exit

Main Menu

Optional Features

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 15

Pressing the down arrow from Calibration will display Configure. To select Configure functions, press ENTER

To continue scrolling the list,press the down arrow. Press ESC to return to the measure screen.

Pressing the down arrow from Configure will display DataStick Comms. To select DataStick Comms

functions, press ENTER. To continue scrolling the list, press the down arrow. Press ESC to return to the

measure screen.

Pressing the down arrow from DataStick Comms will display Analog Output. To select analog output

functions, press ENTER To continue scrolling the list, press the down arrow. Press ESC to return to the

measure screen.

Pressing the down arrow from Analog Output will display Help. To select Help functions, press ENTER To

continue scrolling the list,press the down arrow. Press ESC to return to the measure screen.

Main Menu

Analog Output

MENU

ESC

ENTER

Main Menu

DataStick Comms

MENU

ESC

ENTER

Main Menu

Configure

MENU

ESC

ENTER

Main Menu

Calibrate

MENU

ESC

ENTER

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 16

Pressing the down arrow from Help will display Reset AV38. To select Reset functions, press ENTER To

continue scrolling the list,press the down arrow. Press ESC to return to the measure screen.

To return to the measure screen press ENTER when in the EXIT screen. Pressing ESC from any screen will

take the user up one level. In this example ESC will also take the user to the measure screen. Since this

screen is at the bottom of the main menu list, the down arrow will not work here. The up arrow can be used to

go back through the list.

Main Menu

Help

MENU

ESC

ENTER

Main Menu

Reset AV38

MENU

ESC

ENTER

Main Menu

Exit

MENU

ESC

ENTER

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 17

6. Calibration

6.1. Span Calibration

To calibrate the span for the Drinking Water Turbidity System:

1. Drain the sample chamber.

2. Shutoff flow to the sample chamber.

3. Remove the chamber lid and place it on top of the AV38.

4. Rinse the chamber with clean water and then with a small

amount ofcalibration solution.

5. Shutoff the Drain.

6. Fill the sample chamber with 40 NTU calibration solution. The formazin should overflow the OUTLET weir

located about of the way to the top of the sample chamber. The 40 NTU calibration standard must be

prepared from a stock solution of 4000 NTU and used within 24 hours. Refrigerate whenstored.

7. After filling the sample chamber with formazin, wait for the reading to settle (less than a minute depending

on the filter setting).

8. Perform a 1-pointsample calibration as shown in the following menu tree.

Be careful topour formzin directly into the SAMPLE CHAMBER. Do not

pour formazin into the Bubble trap.

During this operation, water will remain in the BUBBLE TRAP and it is

not necessary to remove it.

Sample Chamber

Bubble Trap

Sample Chamber

with Lid Removed

Drain Chamber, Shutoff Inlet

Drain and Inlet are shutoff: Ready to calibrate

Thermo Scientific AquaSensors™AquaClear™Low Range Turbidimeter User Guide 18

The complete calibrate menu for the turbidity and suspended solids is shown.

From the measure screen, press MENU.

Fromthe Main Menu,use the up/down arrows to select Calibrate. Then press ENTER.

From the Calibrate Menu, use the up/down arrows to select 1-Point Sample. Then press ENTER.

Calibrate

1-Point Sample

MENU

ESC

ENTER

40.16 NTU

13.1 °C

MENU

ESC

ENTER

Calibrate

1-Point Sample

MENU

ESC

ENTER

Zero

Temperature

Exit

Main Menu

Calibrate

MENU

ESC

ENTER

Table of contents

Other Nivetec Accessories manuals