6

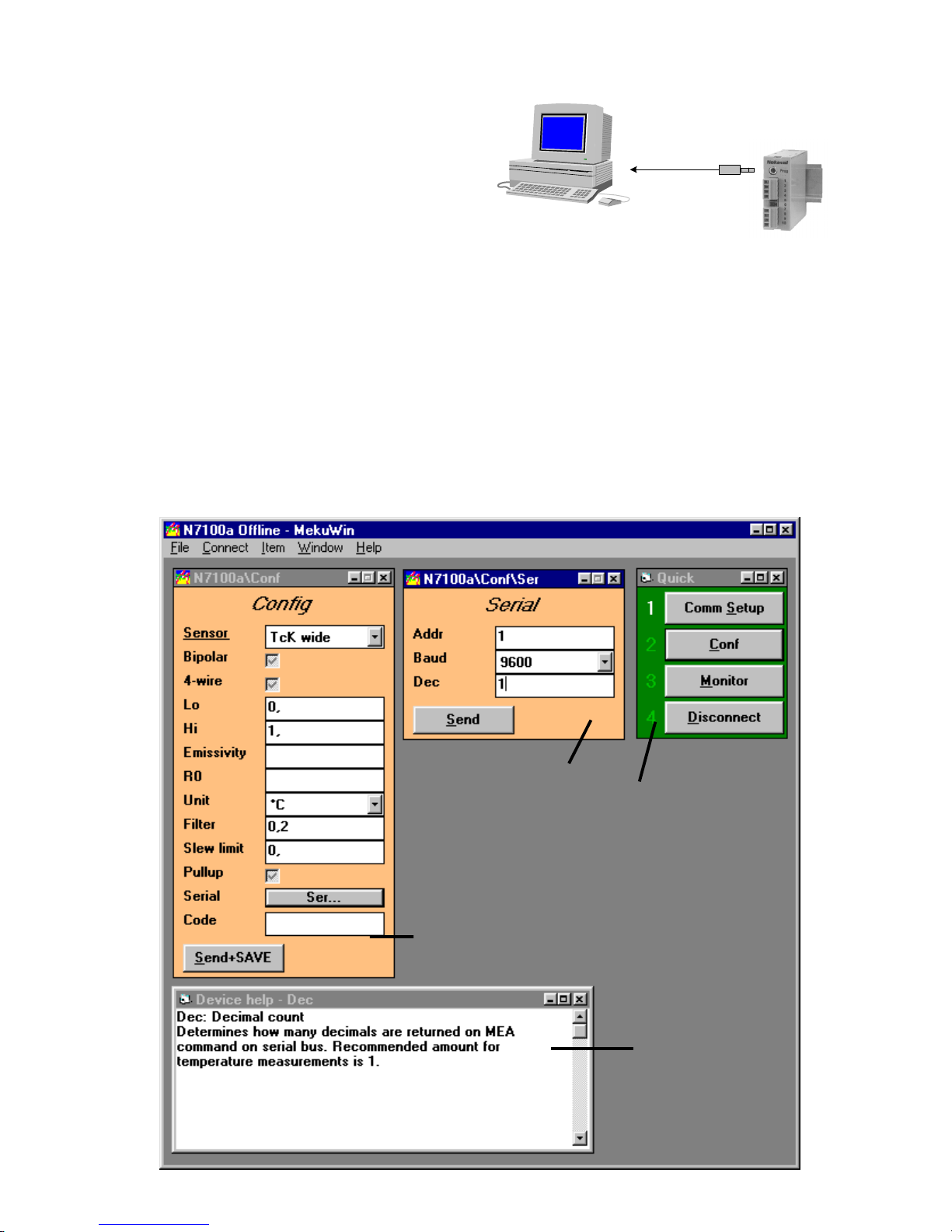

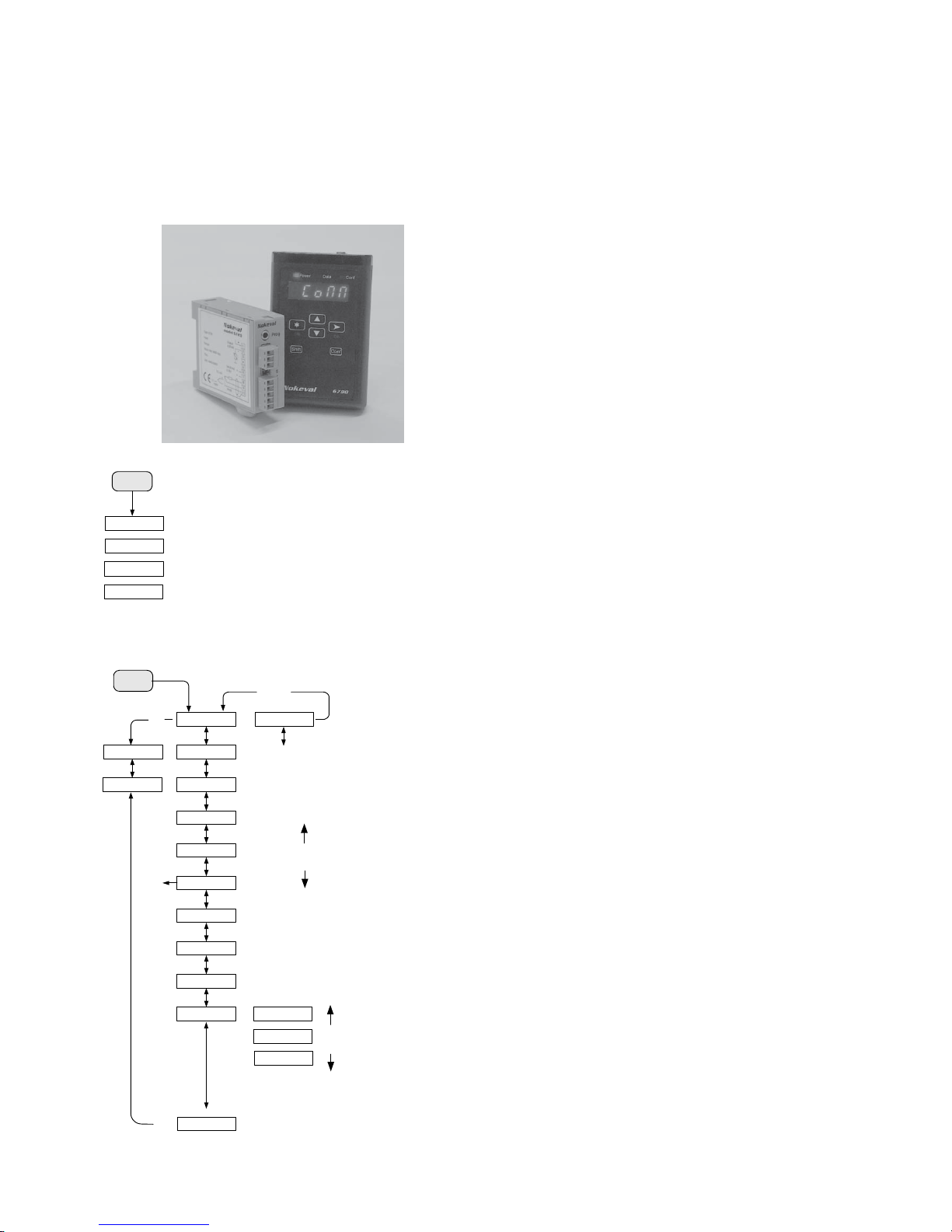

Settings:

In configuration menu select input filtering and scaling of

output. Settings of input and output have

separatewindows(Input,Output).Inaddition,serialsignal

(Serial) has its own window which is needed only when

modem card is installed in transmitter (model 6725).

After sensor selection you may set various correcting

coefficients and filters.

When you install settings, notice whether your PC uses

commaorperiod.Erronousdecimal point is not accepted.

Thermocouple inputs TcB..TcT

Thermocoupletypesare marked shortly Tc+ sensor,f.ex.

TcB=B-type, TcK=K-type etc.. Type K has two ranges.

Narrow range TcKn (-80…+450) has better linearization.

Broader range TcK covers whole range

(-150..+1370 C). If sensor signal is too small or too big,

thevalue can becorrected byEmis-value. F.ex.you want

to correct sensor value at its max. reading by +2 %. Set

Emis-value 0.98. Default value is 1.

Correction of thermocouple sensor error

Thermocouplesarelinearizedtotemperature.Sometimes

youneed to correctsensorsignal.ByIR-thermopilesensor

this need depends on the emissivity of target device.

Emis-coefficient has following effect:

Differencebetweenmeasuredtemperaturevalueandcold

junction temperature is divided by Emis-value and the

result is added to coldjunction temperature. Finally Lo-

value is added. Emis is reverse value of slope and its

corner point is cold junction temperature or environment

temperature of transmitter.

Tcj = transmitter environment temperature (abt.)

Ts = Uncorrected sensor temperature measured by

transmitter

Tn = corrected temperature to display; true

temperature

6740 calculates Tn = (Ts-Tcj) / (Emis + Tcj + Lo).

The use of slope to correct sensor error (one point

correction): Set Emis = 1, Lo = 0.

Heat sensor to calibration temperature. Measure true

sensor temperature Tn and temperatureTs measured by

6740. Calculate: Emis = (Ts-Tcj) / (Tn-Tcj)

F.ex. true sensor temperature Tn = 27 °C. Temperature

measured by transmitter Ts = 895 °C. Set Correction

coefficient Emis = (895-27 °C) / (900-27) = 0.9942. At

hightemperaturescoldjunction temperature effectisvery

smallin Emis calculation. You may measurecold junction

temperature Tcj easily by connecting jumper to sensor

input.7100showsitscoldjunctiontemperatureatterminal

block.

Temperature measurement with RTD´s

Temperature sensors Pt100, Pt250, Pt1000 and Ni100

are available. Sensor connection 3- or 4-wire.

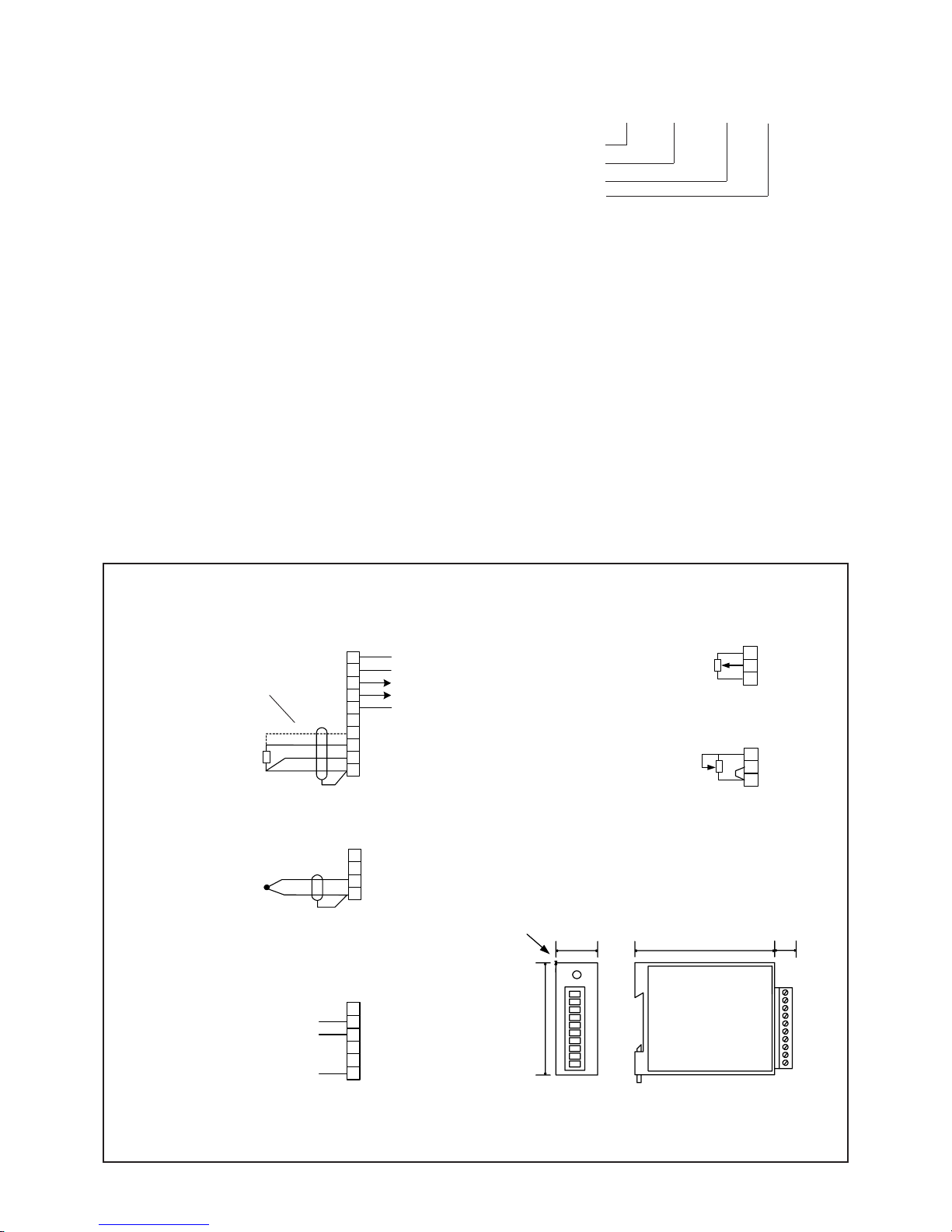

4-wiring requires jumper setting on circuit board, see

picture on page 7.

You can change sensor type by R0-value to

Pt100…Pt1000sensor only by givingresistance value in0

°C, f.ex. for Pt100 sensor R0 = 100.0 ohm or for pt250

sensor R0 = 250.0 ohm etc..

Calibration and error correction of RTD's

7100 assumes that sensor resistance in 0 °C is exactly

R0-setting. This means that 7100 compares sensor

resistance always with R0-setting. If 7100 shows too high

temperaturemeasuredbytheindividualsensor, thesensor

resistance is higher than nominal and you must increase

R0-value.

Advantage of this method is that also sensors can be

calibrated by giving the real measured resistance in 0 °C.

F.ex. if sensor resistance in 0 °C is 100.1 ohm, R0-value

will be 100.1 ohm.

Eliminating sensor tolerance may be done, if necessary,

also in other than 0 °C temperature. Because Platin

resistancesensors arenotfullylinear, you havetocalculate

R0-value according to equation below (other than 0 °C

temperaturecorrections)whenhighaccuracyisrequested.

R0 = valid R0-setting (f.ex. Pt100=100)

R0n = corrected R0-setting (equation below)

Ts = Uncorrected sensor temperature measured by

transmitter

Tn = corrected temperature to display; true

temperature

Kpt = Temp. coefficient of platin in RTD-table

corresponding temp. in question (abt. 0.385

ohm/°C)

Calculate new R0:

R0n = R0 * ( Ts * Kpt + 1 ) / (Tn * Kpt + 1)

F.ex. Sensor true temp. Tn = 100 °C and 7100 shows Ts =

99.7 °C, R0 = 100 (basic value).

Calculate correction R0n = 100 * ( 99.7 * 0.385 + 1 /

(100 * 0.385 + 1) = 99.71

Potentiometers

Potentiometer resistance value is 50…500 ohm by 3-wire

connectionand 0…1000 ohm by2-wire connection. When

potentiometer glide moves from one end to the other of

the potentiometer range , display value turns into Lo…Hi.

As you do not always use the whole potentiometer range,

thismustbenoticedinscaling.Theeasiestwayistoexploit

output scaling as follows: set in input window f.ex. Lo=0

and Hi=100. Drive potentiometer from beginning to end

and notice display values of 7100 (monitor). Set these

valuesinoutputwindow as Lo- and Hi-values of mA-output.

When performing variable resistance measurement

(0…1000ohm),thescalingisdonelikeinpointAbs.sensor

inputs.The sensor selection in menu = ohm.

0/4..20 mA and 0..5/10V process inputs

Inputranges: 0-5V,0-10V,0-20mA,4-20mA.When process

signalis selected,scaletheinput firstdirectlyasengineering

units on monitor display. Set min. (Lo) and max. (Hi)

corresponding value, f.ex. input 0-10V corresponds in

display range 200-500. Set Lo=200 and Hi=500 (output

range is set in its own window). In case of V-input, the

jumperof the measuringcard mustbe in position1-2 (mV-

inputs do not need jumper setting).