www.hawkeyeelectronics.com

OTICE

If you need to increase the length of the transducer cable order part

# ACC-DF-1130 from our website. Strip back the rubber cable cover

1” (28 mm) exposing the three internal wires (blue, white, and bare)

on your transducer. Using a soldering iron, solder the

and bare wires from the extension cable to the corresponding wires on your

transducer. Using electrical tape, or heat shrink tubing make certain that the

soldered connections are completely sealed and protected against accidental

electrical interference and corrosion. Cutting the plug off the Digital Depth

Sounder display will void the warranty.

STEP 5

Antifouling Paint

Marine growth can accumulate rapidly on the transducer's surface. If the vessel

is left in saltwater for extended periods of time, all components of the transducer

below the waterline must be painted with WATER BASED antifouling paint.

•Never use ketone-based paint, as this type of paint can damage the

transducer's plastic shell.

•Clear, spray-on antifouling paints are very easy to apply and can be

purchased from your local boating supply store.

•Reapply paint as needed to prevent marine growth

STEP 6

Testing and Troubleshooting the Transom Mount Installation

1. Make sure that the display is functioning properly by following the display

testing procedures in the Display Installation and Operation Manual.

2. Place the vessel in the water. Once the display is turned ON, it will display

the test sequence and then display the current depth.

3. Become familiar with the depth sounder’s function and performance at idle

speeds.

4 Gradually increase the boat speed and observe the depth readings (pay

attention to minimum and maximum depth capabilities).

5. If "---" readings appear:

•Check to make sure that the transducer is not "kicked-up". To prevent

damage to the transducer, it will automatically release from the mounting

bracket (kick-up) when it is impacted. If this occurs, refer to Page 4 of this

manual to reset the transducer for normal operation. If this happens

frequently, make sure that the trailer or boat lift bunks do not interfere with

the transducer during loading and unloading.

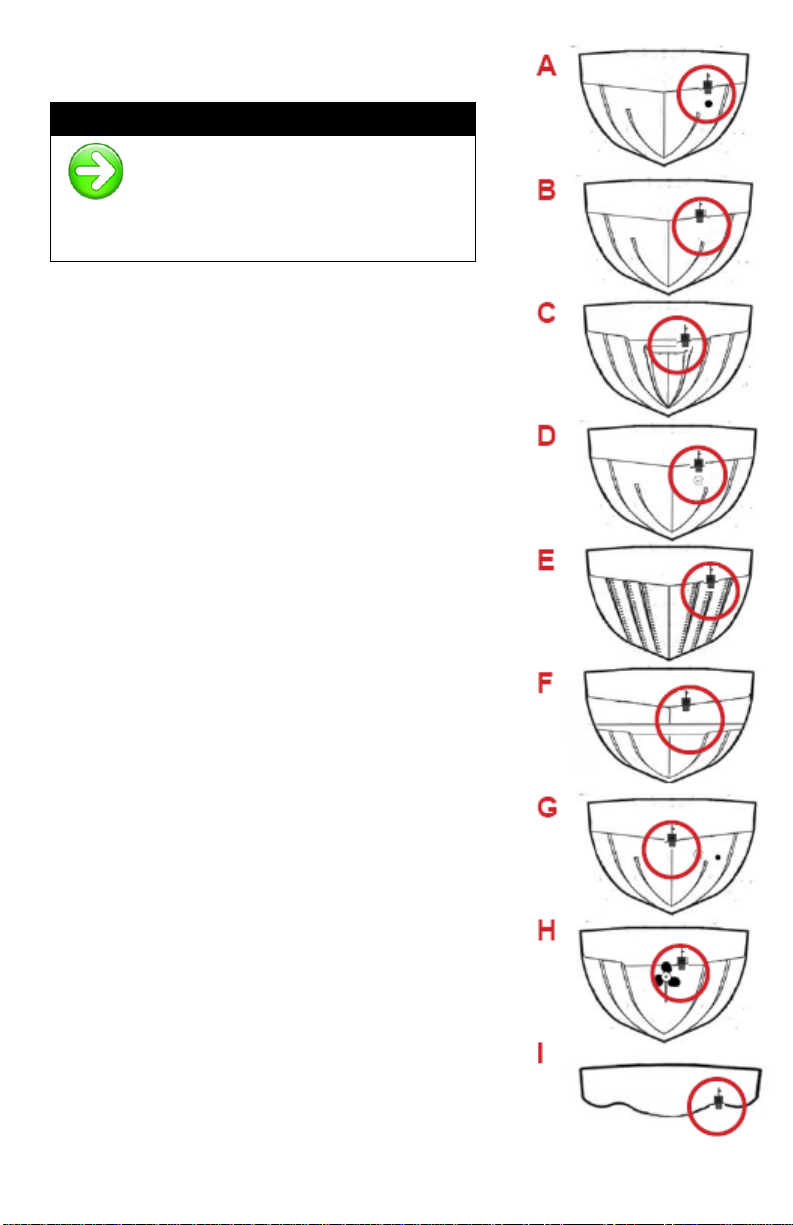

•Have someone run the boat on plane for you in smooth water.

CAREFULLY look over the transom at the water flowing from the bottom