3

NO

Maling

Når peisen er ferdig sparklet/slipt og limskjøtene tørre,

er peisen klar til å males. Bruk kun pustende maling

(akryl) ment for murverk. Dersom det ønskes struktur

kan det blandes litt iselim i malingen.

Behandling av marmor

Rengjør platene med svakt såpevann og fjern alle

eventuelle rester av limsøl.

Bruk aldri syreholdige/slipende stoffer da disse vil

ødelegge både overate og polering.

Ved rengjøring eller fuging er det viktig å bruke

vaskemidler/fug som er godkjent for marmor.

Riper i mørk marmor kan farges med blyantbly. Et

steinsenter kan være behjelpelig med ulike produkter

for overatebehandling av stein

For egen sikkerhet, følg monteringsanvisningen. Alle

sikkerhetsavstander er minimumsavstander. Installasjon

av ildsteder må i tillegg være i henhold til det enkelte

lands lover og regler. Nordpeis AS står ikke ansvarlig for

feilmontering av ildstedet.

Vi tar forbehold om trykkfeil og endringer.

For sist oppdaterte versjon og mer utfyllende informasjon

om brannmurer, pipetilkobling etc., se våre nettsider

www.nordpeis.no

2. Før du installerer nytt ildsted

Installasjon og kontroll før bruk

Installasjon av nye ildsteder skal meldes til de lokale

bygningsmyndigheter. Det anbefales å benytte

kompetent personell ved installasjon nytt ildsted.

Huseier står selv ansvarlig for at alle krav til sikkerhet

er ivaretatt på en forskriftsmessig måte og er forpliktet

til å få installasjonen inspisert og sikkerheten bekreftet

av en kvalisert kontrollør. Kvalisert kontrollør kan

være feier, murmester, varmeforhandler eller andre

med tilstrekkelig kompetanse. Det er også en fordel

å dokumentere denne kontrollen skriftlig, bruk gjerne

vedlagte kontrollskjema. Lokalt feievesen må informeres

dersom installasjonen medfører endret feiebehov.

Skorsteinstrekk

Sammenlignet med eldre ildsteder, stiller dagens

rentbrennende ildsteder betydelig større krav til

skorsteinen. Selv det beste ildsted vil fungere dårlig hvis

skorsteinen ikke er riktig dimensjonert og i god stand.

Oppdriften styres hovedsaklig av røykgasstemperatur,

utetemperatur, lufttilførsel og skorsteinens høyde og

innvendige diameter. Anbefalt skorsteinshøyde er minst

4 meter over røykinnføringen og en diameter på 150-

200mm. Skorsteinens diameter skal aldri være mindre

enn røykinnføringen/røykrøret. Ved nominell effekt skal

det være et undertrykk mellom 12 og 25 Pascal.

Trekken øker når:

• skorsteinen blir varmere enn utelufta

• den aktive lengden på skorsteinen over ildstedet

økes

• det er god lufttilførsel til forbrenningen

Er skorsteinen overdimensjonert i forhold til ildstedet,

kan det bli vanskelig å oppnå god trekk, fordi

skorsteinen ikke blir godt nok oppvarmet. I slike tilfeller

kan det lønne seg å ta kontakt med kynding personell

for vurdering av eventuelle tiltak. For kraftig trekk kan

avhjelpes med en trekkbegrenser. Ildstedet er typetestet

og må kobles til skorsteiner som er dimensjonert for

røykgasstemperatur som anvist i EC-deklarasjonen.

Ved behov, ta kontakt med en feier på forhånd.

Tilførsel av luft FIG Ronda AIR

Friskluftsett får å tilknytte ildstedet til luft utenfra fås

kjøpt som tilbehør, og vil sikre at tilførsel av luft til

ildstedet blir mindre påvirket av ventilasjonsanlegg,

kjøkkenvifter og andre forhold som kan medføre

undertrykk i rommet. I alle nybygg anbefaler vi på det

sterkeste at det prosjekteres og klargjøres for direkte

tilførsel av luft utenfra. Også i eldre hus kan bruk av

friskluftsett anbefales. Utilstrekkelig tilførsel av luft

utenfra kan medføre undertrykk i rommet der ildstedet

står - og dermed dårlig forbrenning, dårligere utnyttelse

av veden og nedsoting av skorsteinen.

Krav til gulvplate

Det kreves 30 cm gulvplate foran ildstedet, dersom

gulvet er brennbart.

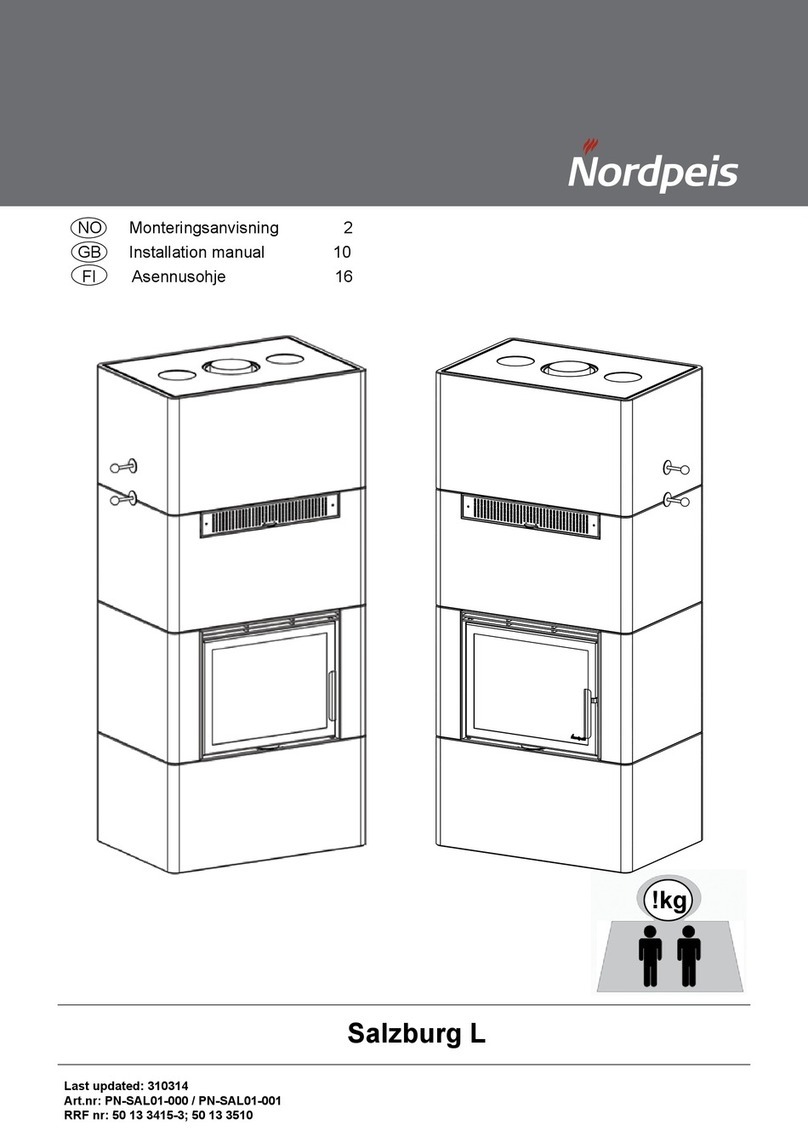

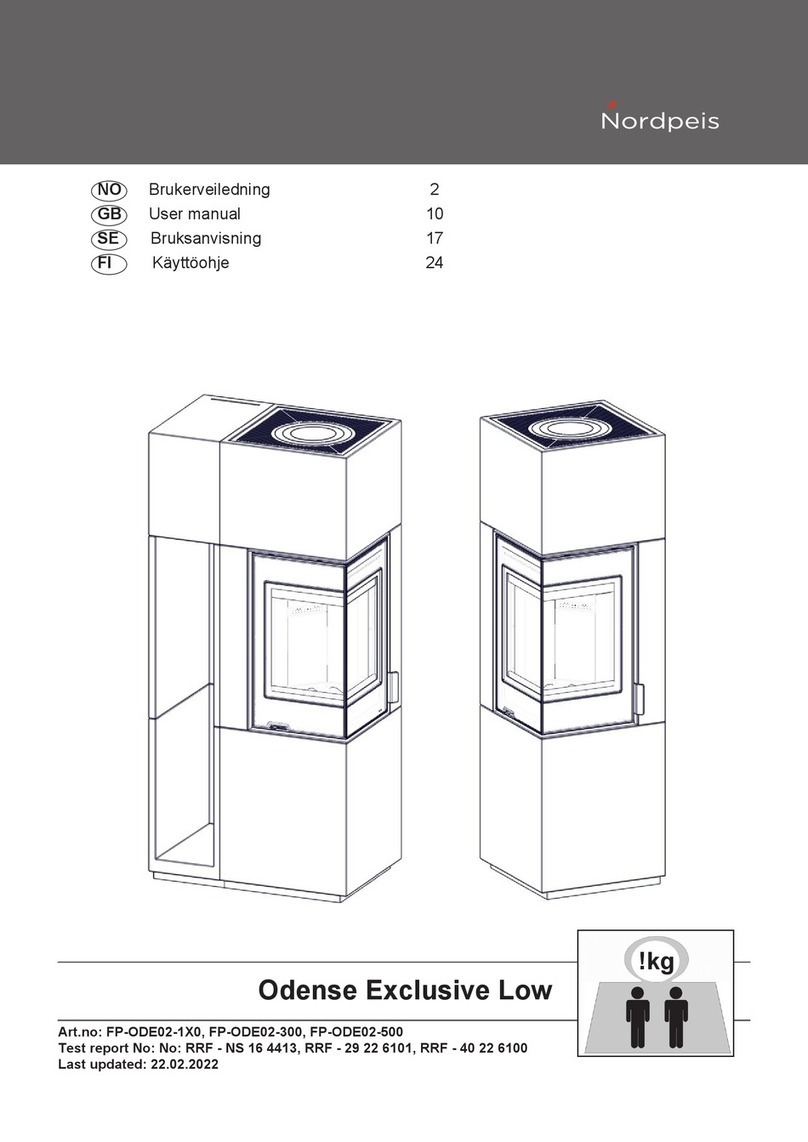

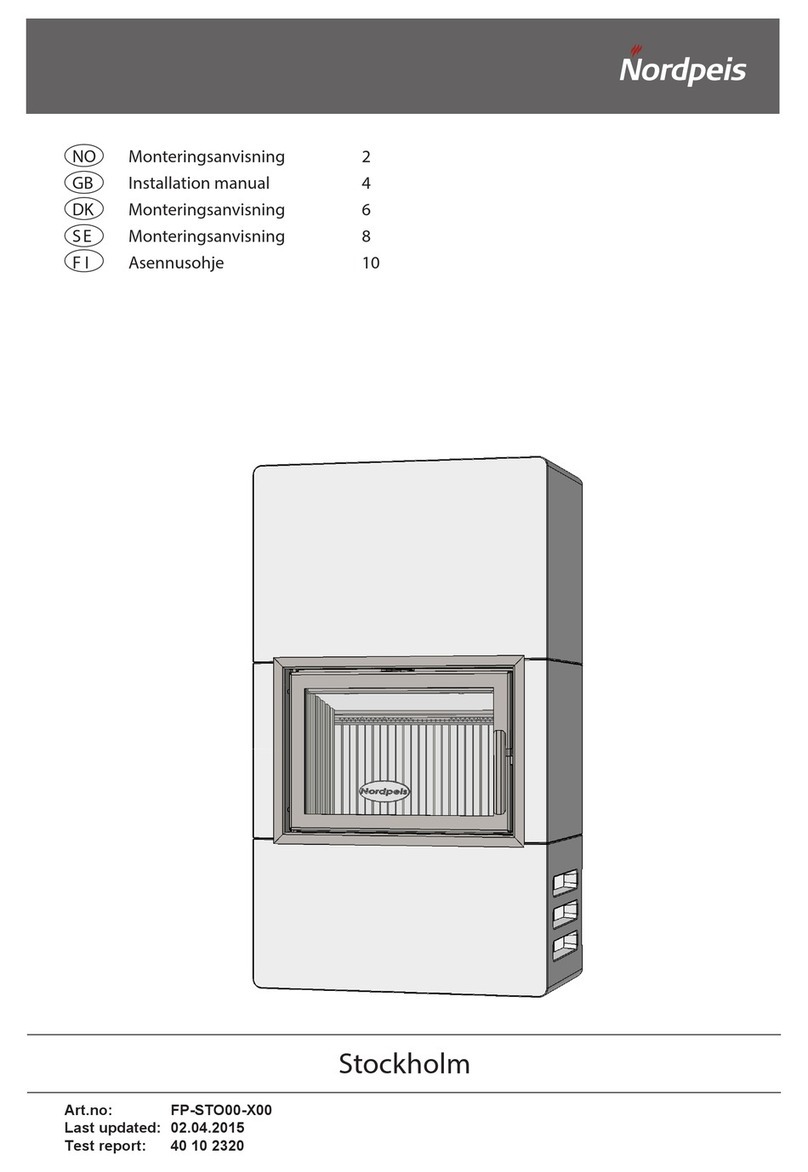

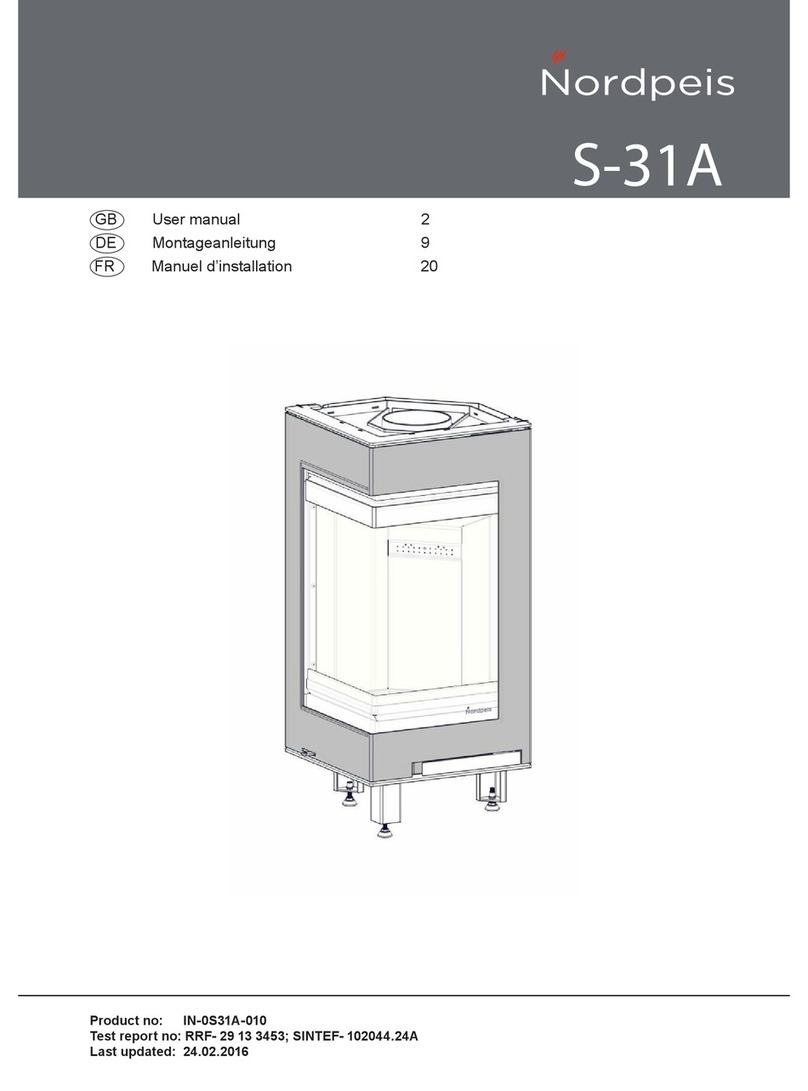

Måltegninger

Måltegningene angir ca. senter høyde for hull til

røykrøret. Skjevheter i gulv og vegger vil kunne påvirke

målene. Tørrstable ildstedet for nøyaktig høyde og

posisjon til røykinnføringen.

3. Teknisk informasjon

Ildsteder fra Nordpeis har sekundærforbrenning og

er rentbrennende. Ved sekundærforbrenning skjer

forbrenningen i to trinn: Først brenner veden, deretter

antennes røykgassene av forvarmet luft. Dette gjør at

nye ildsteder har minimalt med utslipp av sotpartikler

og uforbrente gasser (for eksempel CO) og er bedre

for miljøet. Ved går under betegnelse fornybar ressurs/

biobrensel. Rentbrennende ildsteder trenger lite ved for

å oppnå god varmeeffekt. Fyr utelukkende med ren og

tørr ved.

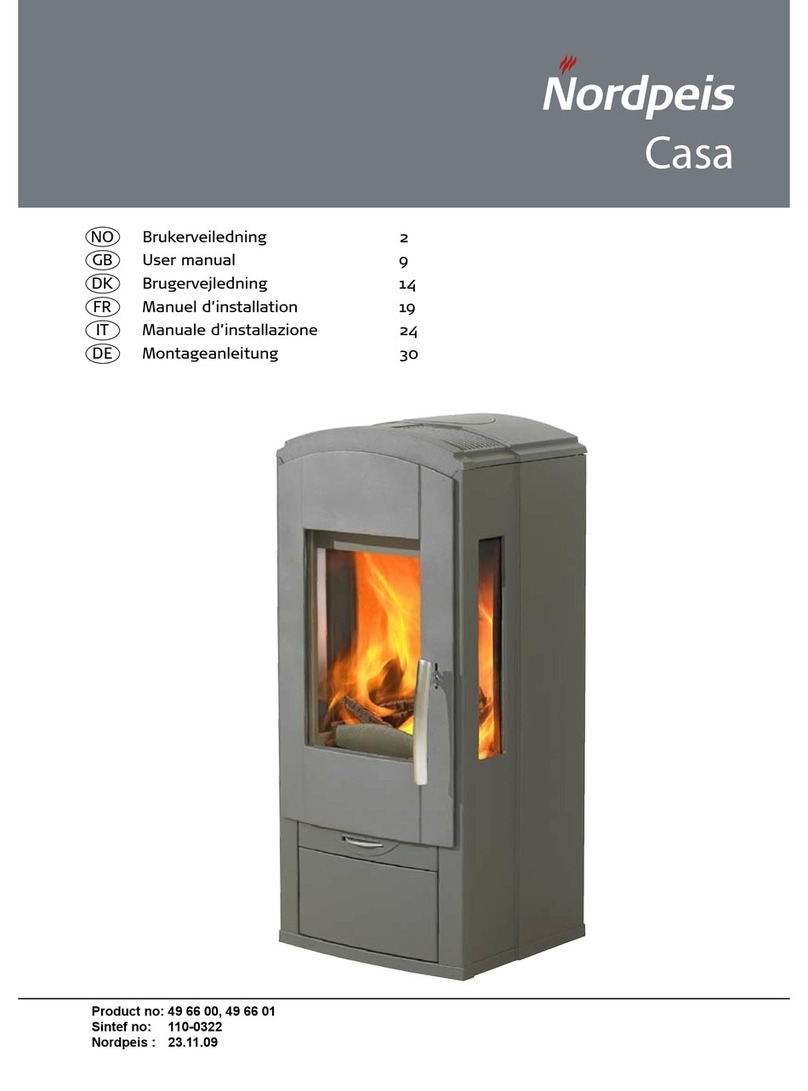

Omramming: Ronda

Innsats: NI-26

Materiale innsats: Støpejern/platestål

Overatebehandling dør/

dørramme:

Varmebestandig lakk

Brensel: Ved, 30 cm

Effekt, nominell: 5 kW