Part 331151C E2003 Nordson Corporation

tents

Table of Contents

Safety 1......................................

Qualified Personnel 1.......................

Intended Use 1.............................

Regulations and Approvals 1.................

Personal Safety 2...........................

High-Pressure Fluids 2....................

Fire Safety 3...............................

Halogenated Hydrocarbon Solvent Hazards 4

Action in the Event of a Malfunction 4..........

Disposal 4.................................

Description 5.................................

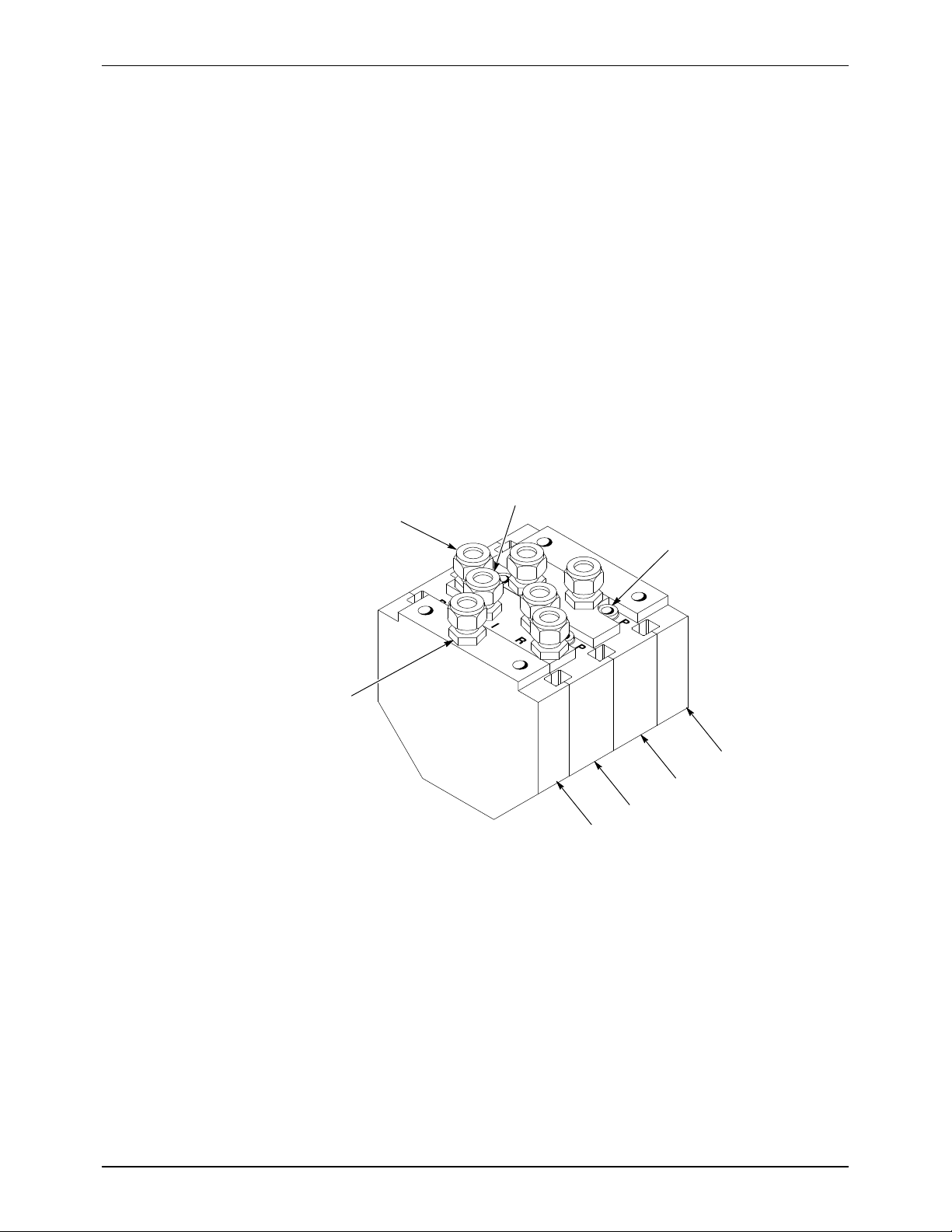

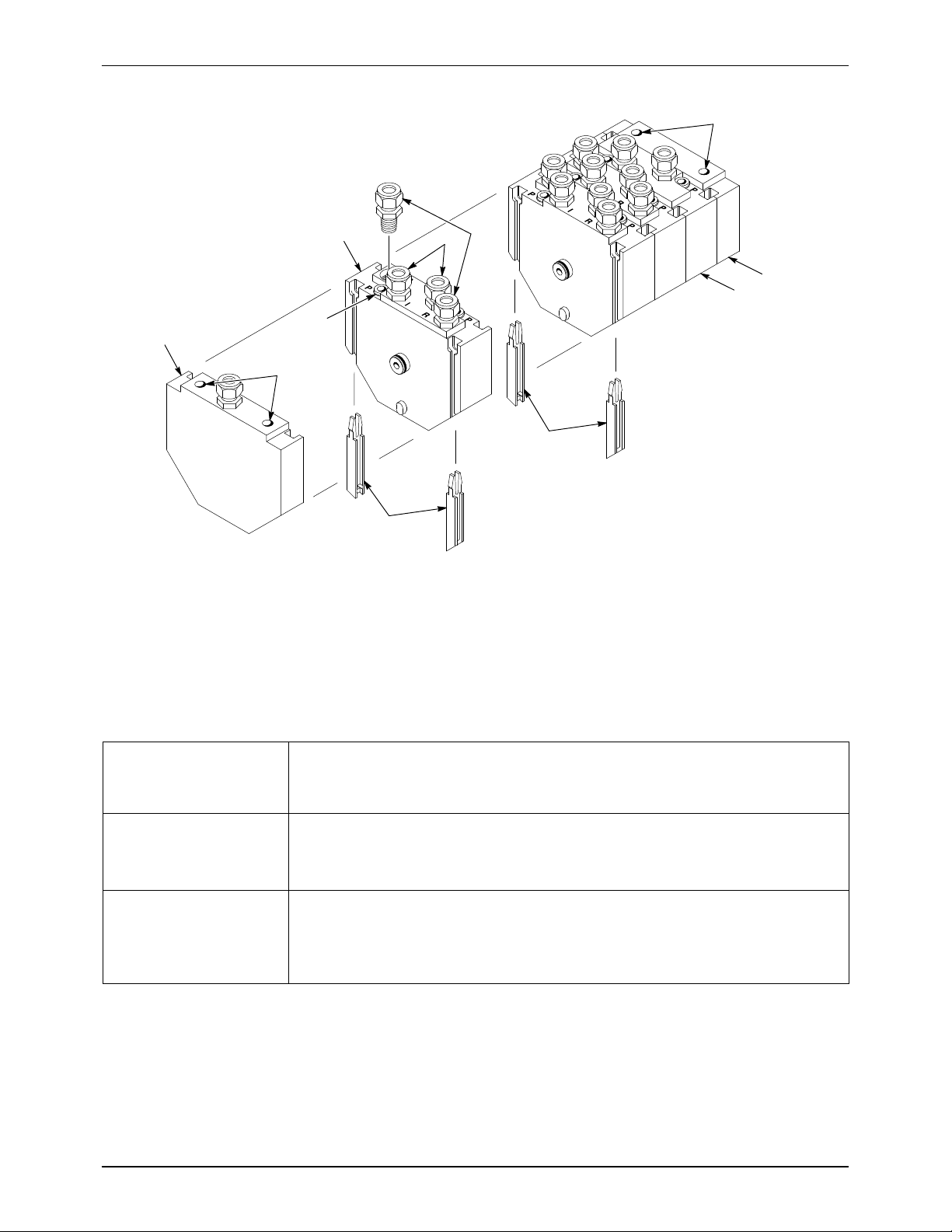

Color Change Plates 6.......................

Color Change Manifold Components 6.........

Options 7...................................

Theory of Operation 8.........................

Installation 9.................................

Fluid Lines 9................................

Air Supply Lines 10...........................

Adding Colors 10.............................

Adding a Divider Plate 10......................

Operation 11..................................

Startup 11...................................

Change Colors 11............................

Shutdown 11.................................

Maintenance 11...............................

Repair 12.....................................

Color Change Manifold Disassembly 12.........

Color Change Manifold Assembly 13............

Microvalve Repair 14.........................

Removal 14...............................

Disassembly 15............................

Assembly 16..............................

Installation 16.............................

Troubleshooting 16............................

Parts 18.......................................

Using the Illustrated Parts List 18..............

Color Change Manifold 19.....................

Female Plate Assembly 20....................

Male Plate Assembly 20......................

Circulating Plate Assembly 21.................

Non-Circulating Plate Assembly 22.............

Microvalve Assembly 22......................

Kits 23......................................

Buna-N, Hot Paint Manifold Air Fitting Kit 23...

Mounting Bar Kits 24.......................

Recommended Spare Parts 25.................

Optional Parts 26............................

Divider Plate Assembly 26..................

Zalak Microvalve O-ring Kit 27...............

Zalak Manifold Air Fitting Kit 27..............

Specifications 28...............................

Contact Us

Nordson Corporation welcomes requests for information, comments, and

inquiries about its products. General information about Nordson can be

found on the Internet using the following address:

http://www.nordson.com.

Address all correspondence to:

Nordson Corporation

Attn: Customer Service

555 Jackson Street

Amherst, OH 44001

Notice

This is a Nordson Corporation publication which is protected by copyright.

Original copyright date 1999. No part of this document may be

photocopied, reproduced, or translated to another language without the

prior written consent of Nordson Corporation. The information contained

in this publication is subject to change without notice.

Trademarks

Nordson and the Nordson logo are registered trademarks of Nordson

Corporation.

Loctite is a registered trademark of Loctite Corporation.

Zalak is a registered trademark of E.I. DuPont de Nemours and Company.