6 Electrical installation

NOTE

All external switching elements and their wiring must withstand an ampacity, maximal

short-circuit load of Imax = 1000 A (according to EN 60947-5-1).

DANGER

Switch the entire machine/system off line!

•The voltage supply must satisfy the regulations for extra-low voltages with safe iso‐

lation (SELV, PELV) for overvoltage category II as per EN 60 664 and EN 50 178.

NOTE

Overvoltage category III can be achieved if the contact circuits Y1/Y2 and 41/42 are

operated in the same circuit as the upstream OSSDs (safety extra-low voltage). For

installation in environments with overvoltage category III, external protection elements

must be used.

•All connections, wiring and cable runs must comply with the required category as

per EN ISO 13 849 and EN 62 061 (e.g. cables laid with protection, individually

sheathed cable with screen etc.).

•Always connect inputs B2 and B4 to the 0V potential of the supply voltage for the

basic devices.

•To protect the contact outputs on the and to increase the service life, the loads

connected must be equipped with, e.g., varistors and RC circuits. Please also note

that the selection of the arc suppression can increase the total response time of

the safety function.

•The output signal switching devices and the external device monitoring (EDM)

must be wired in the control cabinet.

•To prevent the welding of the contacts on the built-in relay, an overcurrent protec‐

tion device with max. 6 A short-circuit protection (duty class gG) is to be integrated

into the current paths (see figure 2, enable current path fuse F2/F3/F4).

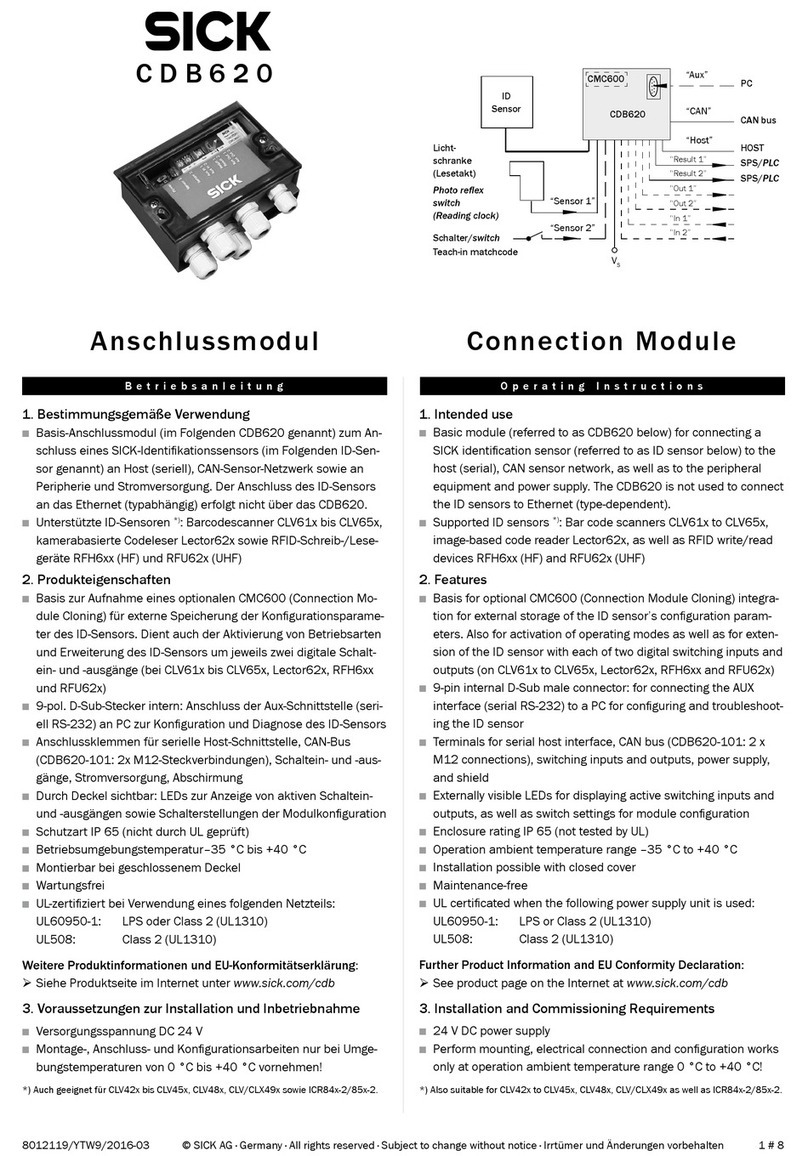

Table 2: Pin assignments

Terminal Description

B1 Input circuit 1

B3 Input circuit 2

B2 0 V

B4 0 V

Y1-Y2 Feedback current path (for usage as external device monitoring)

13-14 Enable current path 1

23-24 Enable current path 2

33-34 Enable current path 3

41-42 Signalling current path (not safe)

Single-channel operation

A jumper is to be connected between B1 and B3. The semiconductor output on the

basic device is to be connected to B1; 0 V on the basic device is to be connected to the

contacts B2 and B4.

Dual-channel operation

The semiconductor outputs on the basic device are to be connected to B1 and B3; 0 V

on the basic device is to be connected to the contacts B2 and B4.

ELECTRICAL INSTALLATION 6

8022191/2017-11-24 | SICK O P E R A T I N G I N S T R U C T I O N S | UE10-3OS 9

Subject to change without notice