Our policy is one of continuous research and development. We therefore reserve the right

to amend, without notice, the specification given in this document.

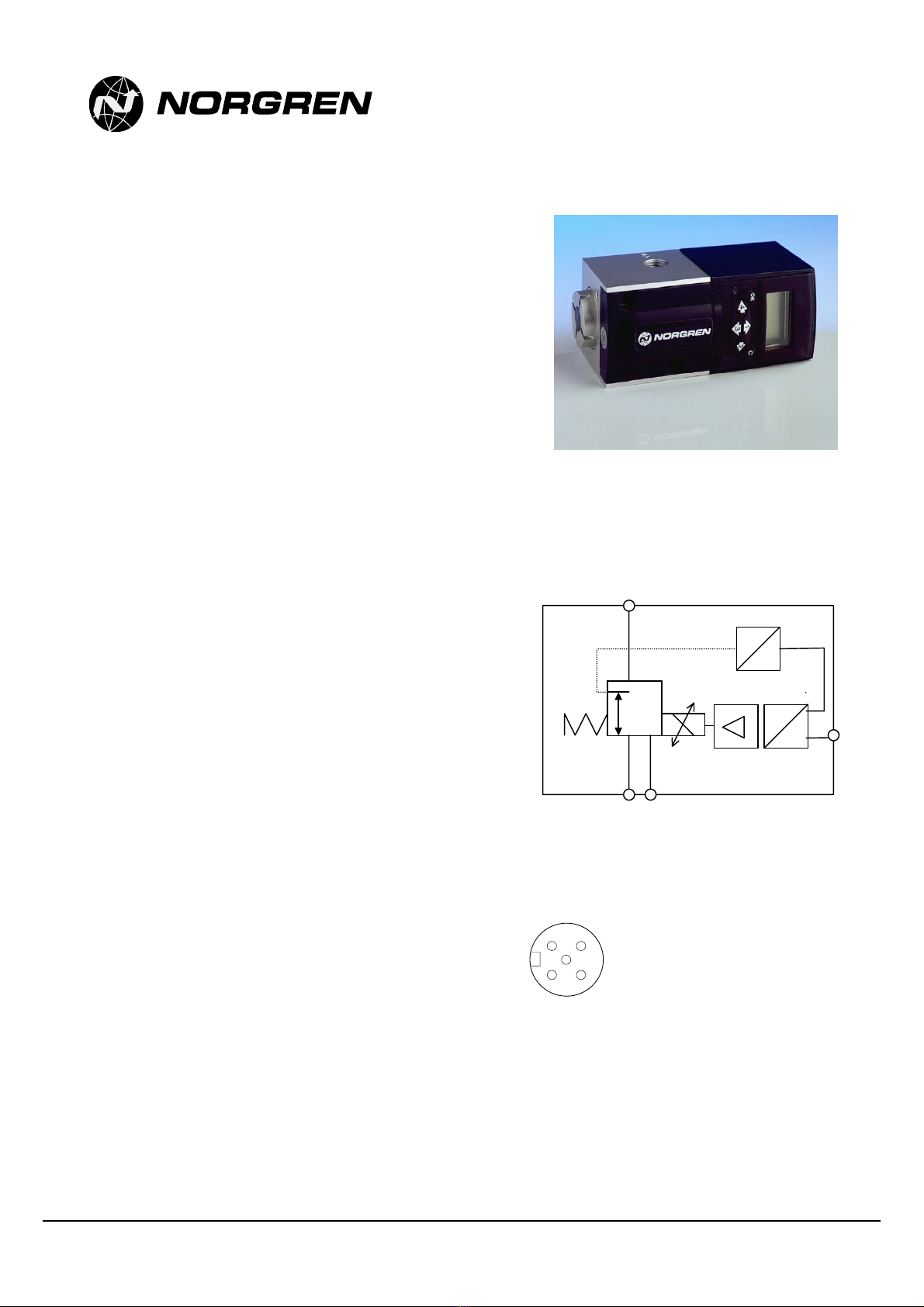

Installation and Commissioning

Pneumatic Installation

Supply Pressure:

Minimum 1 bar (14.5psig) above maximum

required output pressure for function (11 bar

(203psig) max.)

Output Pressure Range:

0-10 bar (0-145psig)

Media:

Clean, dry 5 micron filtered air

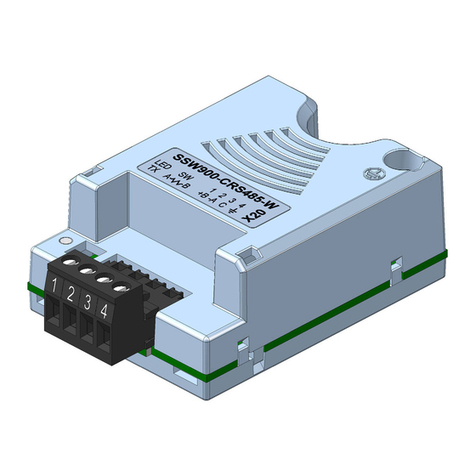

Port Size:

G ¼; ¼”NPT

Connection:

Pipe-work connection using 10mm OD, 8mm

ID, plastic pipe, cut cleanly at right angles, with

push-fit pipe connections.

Exhaust silencer at Port 3 if required (this will

only slightly degrade exhaust performance).

The connector plug must be hand-tight only, to

a tightening force less than 3 Newton.

Mounting:

Any mounting orientation.

Screw mounting through body mounting holes

to suit M4 screws.

Adjustment Controls:

Various via user interface.

Electrical installation

Power Supply:

24V dc power supply (+/- 25% with 250mA

current capability)

Signal:

0-10V, 4-20mA

Feedback:

10V full scale; switch mode settable

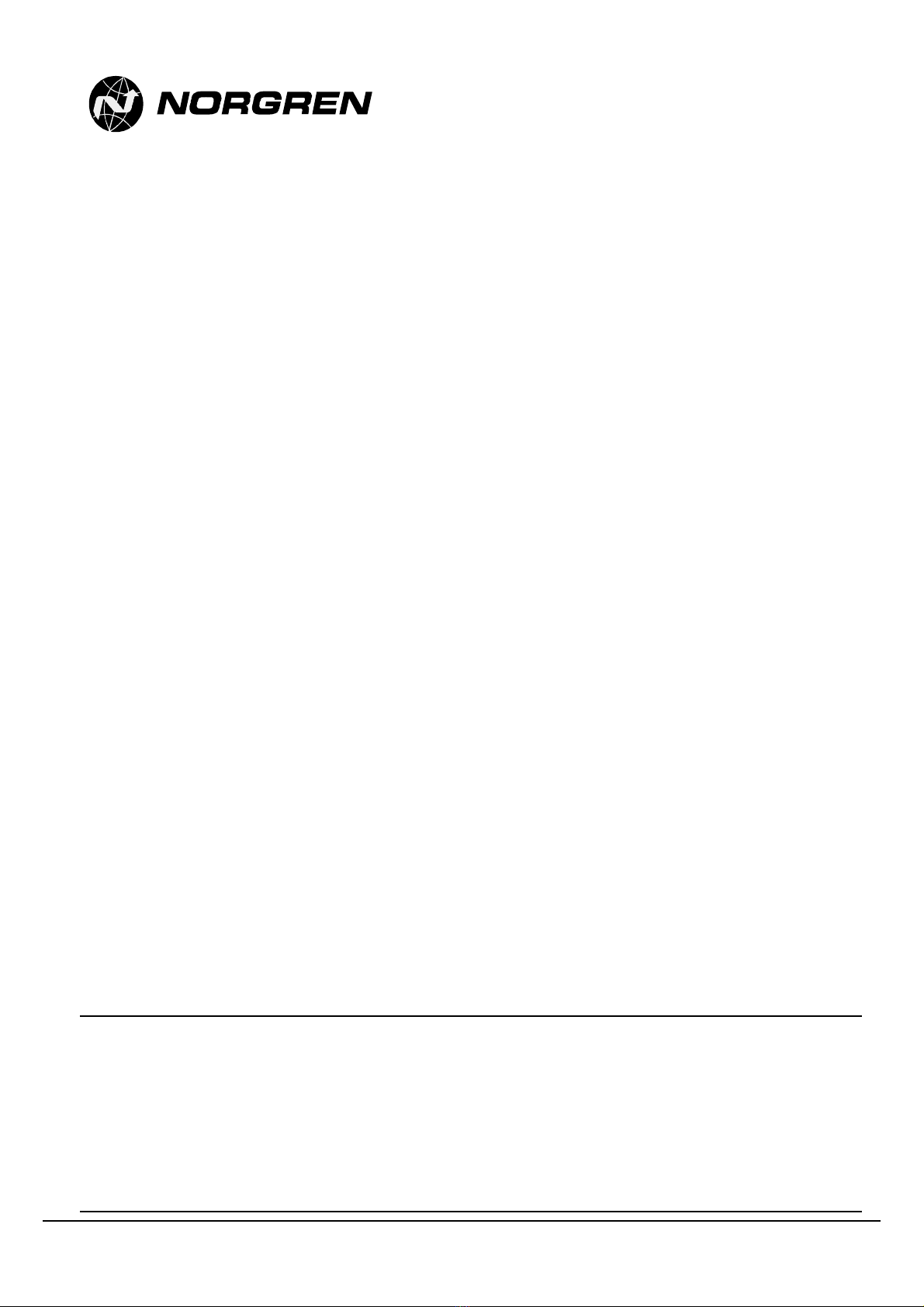

Connection:

5-core, screened cable and M12 socket

connector

Servicing and Repairs

A two year warranty applies to all Norgren products.

For terms and conditions please ask for a copy of

our ‘General Conditions of Sale.’

You should by no means attempt to repair the

product by yourself.

For repair please return the product concerned with

a description of the error, malfunction or failure to

the following address:

IMI Watson Smith Limited

Cross Chancellor Street

Leeds

LS6 2RT

U.K.

or contact us on:

Tel.: +44 (0)1132457587

Fax.: +44 (0)1132465735

E-mail: enquiries@watsonsmith.com

Website: http://www.watsonsmith.com

Transport, Storage and Cleaning

The product can only be transported and stored in

the original Norgren and Watson Smith packaging

which ensures suitable protection against

mechanical damage.

In case it is necessary to clean the product, we

recommend sending it back to the manufacturer.

The correct address can be found under servicing

and repairs.

Warning

These products are intended for use in industrial compressed air systems only. Do not use these products where pressures and

temperatures can exceed those listed under ‘Technical Data’.

Before using these products with fluids other than those specified, for non-industrial applications, life-support systems, or other applications

not within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in fluid power systems can fail in various modes. The system designer is warned to

consider the failure modes of all component parts used in fluid power systems and to provide adequate safeguards to prevent personal

injury or damage to equipment in the event of such failure.

System designers must provide a warning to end users in the system instructional manual if protection against a failure mode

cannot be adequately provided.

System designers and end users are cautioned to review specific warnings found in instruction sheets packed and shipped with these

products.