Norgren VR10 Installation and operating instructions

Operation & Service Manual

VR10 / VR15

With EtherNet/IP Interface

Before starting work read these instructions.

This manual contains proprietary information. No part of this

publication may be reproduced, transcribed or transmitted

in any form without the written consent of the publisher.

Every eort has been made to ensure that the information

contained in this manual is accurate. All rights reserved.

2

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

Change history:

The change history reflects all changes of the Operation & Service Manual, which were done after

the initial release.

Index

Chapters

Change description

Date

Name

001

All

New Release

27-Nov-2020

GG

002

All

Minor changes about pictures and texts

25-Jan-2021

GG

003

7

MS LED Description change

28-Jan-2021

GG

004

6.2.2

Minor changes about texts

09-Mar-2021

GG

005

All

Minor changes to text

24-Mar-2021

JR

This Operation & Service Manual makes no claims of being complete as it does not cover all

variants of the VR10 / VR15 valve islands.

Therefore, this document is subject to extensions or changes.

3

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

1 CONTENTS

1 CONTENTS .................................................................................................................. 3

2 ABOUT THIS DOCUMENTATION ............................................................................... 5

3 IMPORTANT HINTS ..................................................................................................... 6

3.1 GROUNDING AND EQUIPOTENTIAL BONDING ................................................. 6

4 ELECTRICAL COMPONENTS ..................................................................................... 7

4.1 EtherNet/IP PORT 1 & PORT 2 .............................................................................. 8

4.2 POWER SUPPLY CONNECTOR ........................................................................... 8

4.3 ELECTRICAL DATA ............................................................................................... 9

5

SOLENOID NUMBER, OUTPUT POINT & VALVE STATION MAPPING

.................................. 10

5.1 MAPPING RULES FOR VALVE STATIONS £ 12 ................................................ 10

5.2 MAPPING RULES FOR 12 < VALVE STATIONS £ 24 ........................................ 10

6 COMMISSIONING ...................................................................................................... 11

6.1 EDS FILE INSTALLATION ................................................................................... 11

6.2 HARDWARE CONFIGURATION .......................................................................... 14

6.2.1 Add Valve Island and Configuration ............................................................... 14

6.2.2 Assign IP Address to Valve Island ................................................................. 16

6.2.2.1 IP Address Setting by Remote Control ..................................................... 17

6.2.2.2 IP Address Set by Dial Panels .................................................................. 21

6.2.2.3 DHCP Mode .............................................................................................. 21

6.3 DIGITAL OUTPUTS DATA ................................................................................... 22

6.4 DIGITAL INPUTS DATA ....................................................................................... 24

6.4.1 Overall Status Diagnostics ............................................................................. 26

6.4.2 Short Circuit Diagnostics ............................................................................... 28

6.4.3 Open Load Diagnostics ................................................................................. 30

6.4.4 Cycle Overrun Diagnostics ............................................................................ 32

6.5 PARAMETERIZATION ......................................................................................... 34

6.5.1 Cycle Counter Limit ........................................................................................ 34

6.5.2 Open Load Diagnostics Setting ...................................................................... 36

6.5.3 Fail Safe State Setting ................................................................................... 38

6.5.4 Voltage and Short Circuit Diagnostics ............................................................ 40

4

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

6.6 CYCLE COUNTING DATA ACQUISITION ........................................................... 41

6.7 CYCLE COUNTER RESETTING ......................................................................... 44

7 LED STATUS DESCRIPTION .................................................................................... 48

8 TECHNICAL DATA EtherNet/IP INTERFACE ............................................................ 49

9 CUSTOMER SUPPORT ............................................................................................. 50

5

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

2 ABOUT THIS DOCUMENTATION

This User Guide contains the information to set up and operate VR10 / VR15 valve island with

EtherNet/IP

Interface and to detect and resolve problems.

Note:

In addition to the specific information for the

EtherNet/IP

variants, all data sheets and VR10 / VR15

PROTOCOL / MULTIPOLE SERIES IP65 VERSION Operation & Service Manual are applicable and remain valid.

Refer also to the data sheets on the following web link:

§ https://www.norgren.com

Refer also to the valve island installation instruction in the following document:

§

“VR10 / VR15 PROTOCOL / MULTIPOLE SERIES IP65 VERSION Operation & Service Manual”

• This manual can be found on

https://www.norgren.com/uk/en/technical-support/installation-

maintenance-instructions/valves

Basic information about EtherNet/IP could be found in the following documents:

§

“Technology Overview Series: EtherNet/IP”

•

https://www.odva.org/wp-content/uploads/2020/05/PUB00138R6-Tech-Series-

EtherNetIP.pdf

Network Infrastructure for EtherNet/IP could be found in the following documents:

§

"EtherNet/IP Network Infrastructure Guide”

•

https://www.odva.org/wp-

content/uploads/2020/05/PUB00035R0_Infrastructure_Guide.pdf

Further information about EtherNet/IP is available on following websites:

§

https://www.odva.org/

§

https://www.odva.org/technology-standards/document-library/

6

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

3 IMPORTANT HINTS

3.1 GROUNDING AND EQUIPOTENTIAL BONDING

Proper grounding and equipotential bonding are very important to protect against electromagnetic

interferences in EtherNet/IP networks. To reduce potential impact, grounding of the EtherNet/IP

cable screen should be done at both ends of every cable (i.e. at each device). Equipotential

bonding ensures that the ground potential is identical throughout the entire EtherNet/IP network

and is essential to avoid equipotential bonding currents, which could otherwise flow through the

EtherNet/IP cable screen. Please refer for further details to the “

Network Infrastructure for

EtherNet/IP

” provided by the

EtherNet/IP

user organization ODVA (https://www.odva.org/).

For proper grounding please use the earth screw (M4) on the upper side of the valve island. For

easy reference see item 6 in chapter 4.

7

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

4 ELECTRICAL COMPONENTS

1- Port 1 for EtherNet/IP

(M12 x 1 | Female | 4 – pin | D – coded)

2- Port 2 for Ethernet/IP

(M12 x 1 | Female | 4 – pin | D – coded)

3- PWR: Power supply connector

(M12 x 1 | Male | 5 – pin | A – coded)

4- Status LEDs

5- IP address switch.

6- Earth screw (M4)

7- Valve status LEDs

8

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

4.1 EtherNet/IP PORT 1 & PORT 2

M12 / 4 pins / Female Connector / D-coded

Pin No.

Function

1

Transmission Data + (TD +)

2

Receive Data + (RD +)

3

Transmission Data - (TD -)

4

Receive Data - (RD -)

4.2 POWER SUPPLY CONNECTOR

§ Pin allocating of power supply connector

M12 / 5 pins / Male Connector / A-coded

Pin No.

Function

1

L1 (VB +) 24V electronics power supply

2

N2 (VA -) 0V valves power supply

3

N1 (VB -) 0V electronics power supply

4

L2 (VA +) 24V valves power supply

5

FE (functional earth)

§ Power supply connector wiring diagram

Notes:

§ Make sure electronics power, valves power and their polarities are connected to correct pins

respectively before switching on.

§ Select the appropriate cables to mate with the connectors mounted on the control module.

§ Connect the earth screw to ground.

24V DC

Valve Island

24V DC

9

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

4.3 ELECTRICAL DATA

Specification

Remark

Valve voltage range (VA)

24VDC +10%/-5%

PELV

Electronics voltage range (VB)

24VDC +/-10%

PELV

Maximum currents

VA: n × 40 mA

VB: < 100 mA

n = number of solenoids

Voltages are galvanic decoupled

Yes

---

Protection against polarity reversal

Yes

---

Overcurrent protection VB, VA

Irreversible

---

Output polarity

PNP

---

10

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

5 SOLENOID NUMBER, OUTPUT POINT & VALVE STATION MAPPING

5.1 MAPPING RULES FOR VALVE STATIONS

£

12

§ If valve stations ≤ 12, 2 solenoid numbers are always reserved for each valve station. *

Detailed allocation is shown as below:

Station

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

#12

Solenoid A

(14 Solenoid)

Sol.01

Sol.03

Sol.05

Sol.07

Sol.09

Sol.11

Sol.13

Sol.15

Sol.17

Sol.19

Sol.21

Sol.23

Output

0

Output

2

Output

4

Output

6

Output

8

Output

10

Output

12

Output

14

Output

16

Output

18

Output

20

Output

22

Solenoid B

(12 Solenoid)

Sol.02

Sol.04

Sol.06

Sol.08

Sol.10

Sol.12

Sol.14

Sol.16

Sol.18

Sol.20

Sol.22

Sol.24

Output

1

Output

3

Output

5

Output

7

Output

9

Output

11

Output

13

Output

15

Output

17

Output

19

Output

21

Output

23

Notes:

* For valve station with single solenoid, only Solenoid A (14 Solenoid) is connected.

Consider the one which is closest to control module as 1st station (Station #1)

5.2 MAPPING RULES FOR 12

<

VALVE STATIONS

£

24

§ If 12 < valve stations ≤ 24, special rules are required since only 1 solenoid number is

allocated to valve station with single solenoid:

• Sequence all solenoids following the rules below by starting from 1st station which is the

station closest to control module:

o If 1st station is with double solenoids, sequence solenoid A as Sol.01, solenoid B as

Sol.02, following 2nd station solenoid A as Sol.03, solenoid B as Sol.04……

o If 1st station is with single solenoid, sequence solenoid A as Sol.01, following 2nd

station solenoid A as Sol.02, solenoid B as Sol.03……

o If a station is originally configured as blank, always 2 solenoid numbers are allocated.

o The rest of stations should also adhere to the sequence rules above.

• A 16-station 24 solenoids valve island example is shown below:

Double

Solenoids

Double

Solenoids

Single

Solenoid

Single

Solenoid

Double

Solenoids

Double

Solenoids

Single

Solenoid

Double

Solenoids

Single

Solenoid

Double

Solenoids

Single

Solenoid

Double

Solenoids

Single

Solenoid

Single

Solenoid

Double

Solenoids

Single

Solenoid

Station

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

#12

#13

#14

#15

#16

Solenoid A

(14 Solenoid)

Sol.01

Sol.03

Sol.05

Sol.06

Sol.07

Sol.09

Sol.11

Sol.12

Sol.14

Sol.15

Sol.17

Sol.18

Sol.20

Sol.21

Sol.22

Sol.24

Output

0

Output

2

Output

4

Output

5

Output

6

Output

8

Output

10

Output

11

Output

13

Output

14

Output

16

Output

17

Output

19

Output

20

Output

21

Output

23

Solenoid B

(12 Solenoid)

Sol.02

Sol.04

--*

--*

Sol.08

Sol.10

--*

Sol.13

--*

Sol.16

--*

Sol.19

--*

--*

Sol.23

--*

Output

1

Output

3

Output

7

Output

9

Output

12

Output

15

Output

18

Output

22

Note:

* For valve station with single solenoid, only Solenoid A (14 Solenoid) is allocated & connected.

Consider the one which is closest to control module as 1st station (Station #1).

11

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

6 COMMISSIONING

Notes:

1. The method of module installation strongly depends on the configuration software. Please refer to the configuration

software manual.

2. All examples in this document are made with following tools,

Hardware: Allen-Bradley PLC CPU 1756-L61, Ethernet/IP Module 1756-ENBT.

Software (Rockwell Automation): BootP-DHCP, RS-Linx Classic, RS Logix 5000.

6.1 EDS FILE INSTALLATION

A device description file is needed for configuration of valve island. The ESD file is provided by

NORGREN and can be downloaded from the following web link:

§ https://www.norgren.com/uk/en/technical-support/software

The EDS (Electronic Data Sheet) file could be used for all variants VR10 / VR15:

§ “NORGREN-VR1X-EP-Vxx-JJJJMMDD.eds”

Note: “JJJJMMDD” (JJJJ-year, MM-month, DD-day) is date of release, “Vxx” (xx-version number) is version of release.

The EDS file can be installed inside the engineering tool of the EtherNet/IP controller by following

steps in RS Logix 5000.:

§ Click “Tools” menu.

§ Choose “EDS Hardware Installation

Tool”. Then click on “Next” in

Rockwell Automation’s EDS wizard

window.

§ Select “Register an EDS file(s)”.

Click Next. (Tag 1-2)

12

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

§ In next window, click on

“Register a single file”. (Tag 3)

§ “Browse” to the source path

where EDS file is stored, then

click on “Next”. (Tag 4-5)

§ Click “Next” on the EDS File

Installation Test Result window.

(Tag 6)

13

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

§ Click “Next” by accepting the default

icon of Norgren valve island. (Tag 7)

§ Click “Next” on the task summary

window. (Tag 8)

§ Click Finish. (Tag 9)

§ Now the EDS file is added to the

engineering tool.

14

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

6.2 HARDWARE CONFIGURATION

Note: please create a new project or open an existing project before configuring any hardware.

Please make sure the EtherNet/IP module has been configured correctly before add valve island

moudle in the “Controller Organizer” window in RS Logix 5000 as below.

6.2.1 Add Valve Island and Configuration

§ Find the EtherNet/IP module in controller

Organizer. (Tag 1)

§ Right-clicking on “Ethernet”. (Tag 2)

§ Choose “New Module”. (Tag 3)

§ In the “Select Module Type” window,

filter by key word “Norgren” if too

many module types in “Catalog”.

(Tag 4)

§ Select correct module type. (Tag 5)

§ Click create. (Tag 6)

15

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

§ In the “New Module” window, select

“General” tab, input Name and IP

address. (Tag 7-8)

§ Select “Connection” tab. (Tag 9)

§ Set “Requested Packet Interval (RPI)”

greater than or equal to 10ms. The RPI

times has a direct impact to the busload.

(Tag 10)

§ Click “OK”. (Tag 11)

Note: The lower the cycle times, the higher the

busload

§ Now the valve island is added to the tree

“Controller Organizer”.

16

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

6.2.2 Assign IP Address to Valve Island

VR10/VR15 provides several options to assign IP address to valve island by removing the window

to set the rotary and DIP switch with a 2mm slotted screwdriver during power off.

The detail functions of the switches are shown as below:

Note: VR10/15 supports static and DHCP IP assignment method, for users of other IP assignment

methods (such as BOOTP), please refer to 6.2.2.1 with BOOTP_DHCP server or DHCP server

which is typically provided by PLC OEM (such as BOOTP_DHCP tool within RS Logix 5000

software package from Rockwell Automation) to assign IP address.

IP address dial panels:

0 0 0: IP address set by Remote Control

2 5 5: IP address set by DHCP

001-254: IP address set by dial panel.

Address from 192.168.*. 001 to 192.168.*. 254

“*” is set by “setting switch 1”

Settings - Select additional IP address range.

Switch 1 is “ON” side:

IP address range: 192.168.1.001 to 192.168.1.254

Switch 1 is at opposite “ON” side:

IP address range: 192.168.0.001 to 192.168.0.254

Notes:

001-254 is set by dial panels.

Switch 1 does not take effect under Remote control

and DHCP mode.

Switch 2 is not used.

ON side

17

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

6.2.2.1 IP Address Setting by Remote Control

In remote control mode, IP address can be set by DHCP server, or TCP/IP Interface Object.

§ IP address set by DHCP Server

VR10/VR15 is set as a DHCP client in remote control mode by default.

IP Address must be assigned using a DHCP server or a similar tool.

The IP address must be set again after each power cycle.

The following example shows the IP Address assignment using Rockwell Automations tool

BOOTP_DHCP.

In the BOOTP_DHCP tool, making sure network adaptor which is in the network is selected.

Then follow the steps below:

• In the “commissioning tool” window,

click Add Relation. (Tag 1)

• Enter Client Address (MAC), IP

Address and Hostname in the “New

Entry” window, Click OK. (Tag 2-3)

• The relation now is added.

• Select the added relation. (Tag 4)

• Click “Enable BOOTP/DHCP”. (Tag 5)

• The VR10/VR15 valve island will

appear with assigned IP Address in

“Discovery History” list if address

assignment was successful. (Tag 6)

18

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

§ Static IP Address assignment

Static IP address must be done once and is valid after power cycles.

The following example shows how to set static IP address by Rockwell Automation tool

BOOTP/DHCP.

• Click Add Relation. (Tag 1)

• Enter Client Address (MAC), IP

Address and Hostname. (Tag 2)

• Click OK. (Tag 3)

• Select the added relation. (Tag 4)

• Click “Enable BOOTP/DHCP”. (Tag 5)

• The VR10/VR15 valve island will

appear with assigned IP Address in

“Discovery History” list if address

assignment was successful. (Tag 6)

• Right-clicking on the relation. (Tag 7)

• Select “Disable BOOTP/DHCP”.

(Tag 8)

19

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

• “[Disable DHCP] command

successful” will appear in the

Errors and warnings status.

20

Operation & Service Manual

VR10 / VR15 with EtherNet/IP Interface

Construction & Design is subject to change (A1743-OPM-EP / Rev.004)

§ Static IP address can also set by TCP/IP Interface Object.

The Read/Write access to the TCP/IP Interface Object is done via the Explicit Messages

communication method.

The configuration method is set up with the bits0-3 in attribute 3. Please use the statically

assigned IP configuration set up value “0” for those bits.

Bit(s):

Called:

Definition

0-3

Configuration

Method

Determines how

the device shall

obtain its IP-

related

configuration

0 = The device shall use statically assigned IP configuration

values.

1 = Not used.

2 = The device shall obtain its interface configuration values

via DHCP.

3-15 = Reserved for future use.

4

DNS Enable

If 1 (TRUE), the device shall resolve host names by querying a DNS server.

5-31

Reserved

Reserved for future use and shall be set to zero.

Attribute 3 of TCP/IP Interface Object: Configuration Method

Attribute 5 contains the configuration parameters required to operate as a TCP/IP node. At

least network address and network mask need to be configured.

Name

Meaning

IP address

The device’s IP address.

Network mask

The device’s network mask. The network mask is used when the IP network has been

partitioned into subnets. The network mask is used to determine whether an IP address is

located on another subnet.

Gateway address

The IP address of the device’s default gateway. When a destination IP address is on a

different subnet, packets are forwarded to the default gateway for routing to the destination

subnet.

Name server

The IP address of the primary name server. The name server is used to resolve host

names. For example, that might be contained in a CIP connection path.

Name server 2

The IP address of the secondary name server. The secondary name server is used when

the primary name server is not available or is unable to resolve a host name.

Domain name

The default domain name. The default domain name is used when resolving host names

that are not fully qualified. For example, if the default domain name is “odva.org”, and the

device needs to resolve a host name of “plc”, then the device will attempt to resolve the host

name as “plc.adva.org”.

Attribute 5 of TCP/IP Interface Object: Interface Configuration

Other manuals for VR10

3

This manual suits for next models

1

Table of contents

Other Norgren Control Unit manuals

Norgren

Norgren FD67 User manual

Norgren

Norgren 82 Series User manual

Norgren

Norgren VP51 User manual

Norgren

Norgren VP23 Series User manual

Norgren

Norgren VP60 Series User manual

Norgren

Norgren Prospector A00 5A Series User manual

Norgren

Norgren VS18 Manual

Norgren

Norgren VR10 Instruction Manual

Norgren

Norgren HERION G1/4 User manual

Popular Control Unit manuals by other brands

Ametek

Ametek Z-tron IV Installation and operating instructions

Telit Wireless Solutions

Telit Wireless Solutions ME910C1 Series user guide

ACS

ACS ACM1281U-C7 Reference manual

Xerox

Xerox 2101 Customer release notes

Vision tools

Vision tools MDL600 Technical manual

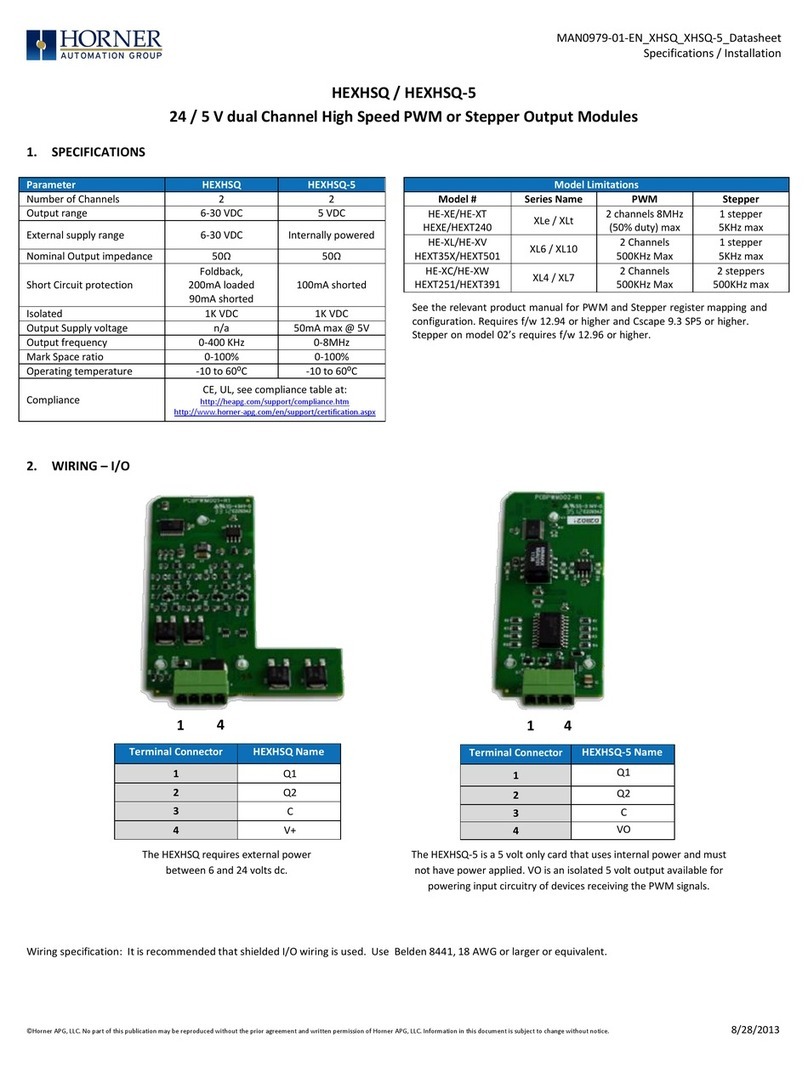

HORNER

HORNER HEXHSQ Specifications & installation