Norgren VR10 Instruction Manual

Installation & Maintenance Instruction

VR10 / VR15

Valve Islands

Before starting work read these instructions.

This manual contains proprietary information. No part of this

publication may be reproduced, transcribed or transmitted

in any form without the written consent of the publisher.

Every eort has been made to ensure that the information

contained in this manual is accurate. All rights reserved.

2

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

Change history:

The change history reflects all changes of the Installation & Maintenance Instruction, which were done after

the initial release.

Index

Chapters

Change description

Date

Name

001

All

New release

27-Nov-2020

GG

002

All

Minor changes about pictures and texts, add ISEM &

External Pilot Base Fittings disassembly/assembly.

27-Jan-2021

GG

003

4

Additional minor comments implemented

4-Feb-2021

GG

004

4

Minor changes about tie rods

18-Feb-2021

GG

005

All

Minor changes to text

23-Mar-21

RL

This Installation & Maintenance Instruction makes no claims of being complete as it does not cover all

variants of the VR10 / VR15 valve islands.

Therefore, this document is subject to extensions or changes.

3

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

1 CONTENTS

1 CONTENTS .................................................................................................................. 3

2 VR10 / VR15 OVERVIEW ............................................................................................ 5

3 SAFETY, WARNINGS .................................................................................................. 8

4 INSTALLATION AND MAINTENANCE ........................................................................ 9

4.1 INSTALLATION AND OPERATION ....................................................................... 9

4.1.1 Overview .......................................................................................................... 9

4.1.2 Tools .............................................................................................................. 10

4.1.3 Tightening Torque .......................................................................................... 10

4.1.4 Port Identification ........................................................................................... 10

4.1.5 Manual Override Operation ............................................................................ 11

4.1.6 Assembling and Disassembling ..................................................................... 12

4.1.7 Piping ............................................................................................................. 33

4.1.8 Multi-Pressure Zone Option ........................................................................... 34

4.2 MAINTENANCE .................................................................................................... 35

4.2.1 Lubrication ...................................................................................................... 35

4.2.2 Valve Identification Information ...................................................................... 35

4.2.3 Spare Parts .................................................................................................... 35

5 TRANSPORT / STORAGE / PACKAGING ................................................................. 35

6 TECHNICAL DATA ..................................................................................................... 36

6.1 SPECIFICATION .................................................................................................. 36

6.1.1 Operation ....................................................................................................... 36

6.1.2 Flow Rate ....................................................................................................... 36

6.1.3 Valve Mounting .............................................................................................. 36

6.1.4 Ambient Temperature .................................................................................... 36

6.1.5 Medium Temperature ..................................................................................... 36

6.1.6 Medium .......................................................................................................... 37

6.1.7 Air Quality ....................................................................................................... 37

6.2 MATERIALS ......................................................................................................... 37

6.3 PNEUMATIC ......................................................................................................... 38

4

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

6.3.1 Response Time .............................................................................................. 38

6.3.2 Push in Fitting ................................................................................................ 38

6.3.3 Valve Function ............................................................................................... 38

6.3.4 Life Expectation .............................................................................................. 39

6.4 ELECTRICAL ........................................................................................................ 40

6.4.1 General Features for Valve Island with Protocols .......................................... 40

6.4.2 General Features for Valve Island with Multipole D-Sub Connector .............. 41

6.4.3 Wiring Rules for Multipole Series ................................................................... 42

6.4.4 Pin Allocating & Wire Colours Identifying for Multipole Series ....................... 45

6.4.5 Wire Connection for Valve Island with Protocols ........................................... 47

6.5 COMPLIANCE AND APPROVALS ....................................................................... 51

6.5.1 CE marking .................................................................................................... 51

6.5.2 REACH ........................................................................................................... 51

6.5.3 RoHS .............................................................................................................. 51

7 CUSTOMER SUPPORT ............................................................................................. 52

5

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

Note: All images shown in this document are indicative only. If there is any inconsistency between the images and the

actual product, the actual product shall govern.

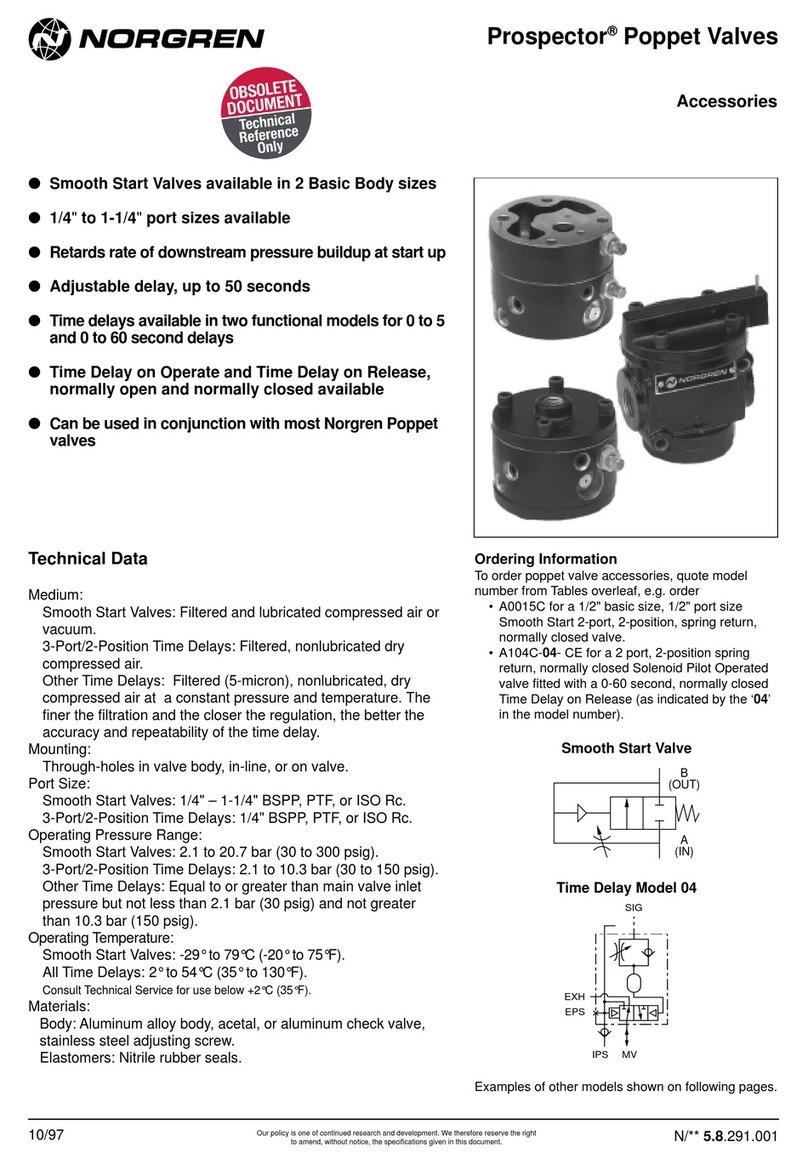

2 VR10 / VR15 OVERVIEW

§ Valve width: VR10: 10mm VR15: 15mm

§ Valve Polarity:

§ Valve island with multipole D-Sub Connector 25-Pin:

• 24 VDC system: Common Negative (PNP) & common Positive (NPN)

• 12 VDC system: Common Negative (PNP)

§ Valve island with protocols:

• Common Negative (PNP) with 24 VDC only

§ Up to 24 solenoids

§ LED indication of solenoid function

§ Ingress Protection:

§ IP40

§ IP65

§ Expansible station with extension kit

§ Easy to replace valves and fittings

§ DIN Rail and base mounting options

§ Modular system with a wide range of configurations

§ To configure and order a Valve Island, visit https://www.norgren.com

6

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

Easy to identify operation with

LEDs next to solenoids.

Solenoid A (14 Solenoid) turns

on red LED, and Solenoid B (12

Solenoid) turns on green LED.

Easy to replace sub-base,

with click together circuit

boards for electrical

connectivity.

Double and single wiring

determined by circuit board.

Industrial universal Electrical Interface

D-Sub Connector 25-Pin IP40 version

Vertical or Horizontal D-Sub Connector easier

installation

Vertical

Horizontal

Possible to select

silencer or blanking

plate.

Excellent interchangeability of control module

Multipole (IP65 Version)

D-Sub Connector

25-Pin

7

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

Certifications

RoHs REACH and CE

External pilot available

for use in low pressure

or vacuum applications

Sup/Exh module available

for multi-pressure

manifolds, or to allow for

additional inlet and

exhaust ports to increase

supply and better exhaust

performance.

Easy to replace fittings.

Fast response

Maximum length of 24

stations/solenoids.

Easy to use Push-In

Fittings with metric and

inch options.

Two mounting options

DIN rail or base

mounting.

Dual 3/2 valves available in 3

configurations.

NC/NC

NO/NO

NC/NO

8

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

3 SAFETY, WARNINGS

This product is intended for use in industrial compressed air system only. Do not use this product where

pressures and temperatures can exceed those under ‘Technical Data’.

Before using this product with fluids other than those specified, for non-industrial applications, life-support

systems, or other applications not within published specifications, consult IMI Norgren. Through misuse, age,

or malfunction, components used in fluid power systems can fail in various modes. The system designer is

warned to consider the failure modes of all component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to equipment in the event of such failure.

System designers must provide a warning to end users in the system instructional manual if protection

against a failure mode cannot be adequately provided. System designers and end users are cautioned to

review specification warnings found in instruction sheets packed and shipped with this product.

Specific warnings:

§ Check that the specification of the Valve Island and marking on the item of the equipment are suitable

for the application it is being used on.

§ Check technical data, such as operating pressure, voltage level, current and temperature, on the

product label or in the data sheets for compliance with the existing operating conditions.

§ After removing the packaging, ensure that no contamination enters the system.

§ Check before the installation of the system that no contamination exists in the piping and valve island.

§ Check during installation of the system that gaskets have not become damaged.

§ Take measures to avoid unintentional or improper activation.

§ Prior to the first electrical operation, ensure no danger would result from the medium exhausting from

any open ports.

§ Consider in case of pressurised systems that lines, valves and other components should not be

removed.

§ To avoid damaging the product, please make sure that the maximum torque values are not exceed.

§ IMPORTANT: Always switch off the air supply, exhaust the residual pressure and unplug all electrical

connections before performing any maintenance.

§ Ensure the machine is in a safe condition before operating manual overrides.

§ Pay due care and attention to the different polarity types available - PNP/NPN.

§ A polarity protection diode is built in: Incorrect polarity does not cause a short circuit and does not

require replacement valve slices. In this case only the LED indicator works, but not the valve slices.

9

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4 INSTALLATION AND MAINTENANCE

4.1 INSTALLATION AND OPERATION

4.1.1 Overview

§ DIN Rail is optional depending on your requirement.

§ 2-10 stations: one Sup/Exh (supply/exhaust) Module is required.

§ 11-24 stations: two Sup/Exh Modules are recommended.

1-Control module

2a-Left Endplate (IP65)

2b-Left end plate (IP40

Version with D-Sub 25pin)

3-Sup/Exh Module

4-Tie rod

5-DIN Rail

6-Sub-base

7-Right end plate

8-Valve

10

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.2 Tools

VR10:

§ Phillips screwdriver size #00

§ Phillips screwdriver size #1

§ Phillips screwdriver size #2

§ Slotted screwdriver 3mm

VR15:

§ Phillips screwdriver size #1

§ Phillips screwdriver size #2

§ Slotted screwdriver 3mm

4.1.3 Tightening Torque

To avoid damaging the product, please follow recommended torque values.

§ M2 screws, torque at 0.15~0.2 Nm (1.3~1.8 lbf·in)

§ M3 screws, torque at 0.4~0.5 Nm (3.5~4.4 lbf·in)

§ M4 screws, torque at 0.7~0.8 Nm (6.2~7.1 lbf·in)

4.1.4 Port Identification

Port Description

Port Identification

Port for Main & internal pilot air supply

P / 1

Port for air exhaust

E / 3 / 5

Port for air outlet

A / 4 & B / 2

Port for external pilot air supply (if used)

12 / 14

Port for collected air exhaust of pilot valves

82 / 84

Note:

Do not plug port 3/5 or 82/84 if the silencer is not

incorporated into Sup/Exh Module.

Plugging either port will cause valves to malfunction.

Port 82/84

Port 12/14

Port P/1

Port E/3/5

Port A/4

Port B/2

11

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.5 Manual Override Operation

VR10:

VR15:

Solenoid A (14 Solenoid)

Manual Push Only

Red button

Solenoid B (12 Solenoid)

Manual Push Only

Green button

Valve Body

Solenoid B (12 Solenoid)

Manual Push Only

Green button

Valve Body

Solenoid A (14 Solenoid)

Manual Push Only

Orange button

12

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.6 Assembling and Disassembling

IMPORTANT:

Pressure and power must be removed from system before assembling & disassembling electrical

connectors, cables, plugs, valves, and blanking plates.

4.1.6.1 Torque List and Its Location

• IP65 Valve Island

1-Control Module

2-Left Endplate

3-Sup/Exh Module

4-Tie Rods

5-DIN Rail

6-Sub-Base

7-Right Endplate

8-Valve Slice

0.15-0.2 Nm | 1.3-1.8 lbf·in (VR10 series)

0.4-0.5 Nm | 3.5-4.4 lbf·in (VR15 series)

0.7-0.8 Nm | 6.2-7.1 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.7-0.8 Nm | 6.2-7.1 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

13

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

• IP40 Valve Island

1-D-Sub Connector

2-Sup/Exh Module

3-Tie rod

4-DIN Rail

5-Sub-base

6-Right end plate

7-Valve Slice

0.15-0.2 Nm | 1.3-1.8 lbf·in (VR10 series)

0.4-0.5 Nm | 3.5-4.4 lbf·in (VR15 series)

0.7-0.8 Nm | 6.2-7.1 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.4-0.5 Nm | 3.5-4.4 lbf·in

0.7-0.8 Nm | 6.2-7.1 lbf·in

14

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.6.2 Assembling and Disassembling Control Module (IP65 Version)

§ Disassemble control module

1) Disassemble all three screws on control module.

2) Pull out control module

§ Assemble control module

1) Push in control module

2) Assemble all three screws on control module.

15

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.6.3 Changing Orientation of D-Sub Connector (IP40 Version)

§ Disassemble D-Sub connector housing

1. Disassemble two screws on D-Sub connector housing

2. Pull out D-Sub connector housing slowly and make sure the wires are not damaged. (Wires are

not shown)

§ Change the orientation as required.

§ Assemble D-Sub connector housing

1. Push and hold D-Sub connector housing to left endplate

2. Assemble two screws on left endplate

D-Sub connector housing

16

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.6.4 Assembling and Disassembling D-Sub Connector (IP40 Version)

§ Disassembling D-Sub connector

1. Disassemble two screws on D-Sub connector

2. Pull out D-Sub connector slowly. Make sure the connector is in its place.

3. Loosen the screw on the D-Sub connector housing if orientation is horizontal.

4. Pull out D-Sub connector housing slowly and make sure the wires are not damaged. (Wires are

not shown)

§ Assembling D-Sub connector

1. Push and hold D-Sub connector to left endplate. Make sure the wires are proper placed.

2. Assemble two screws with correct torque.

3. Push and hold D-Sub connector housing to left endplate

4. Assemble two screws on left endplate

D-Sub connector housing

17

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

IMPORTANT:

1. The red wire must be connected to the upper position as shown below.

2. The PCB fitted must be located into the slot of the cover when assembling D-Sub connector.

18

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

4.1.6.5 Assembling and Disassembling Manifold

§ Disassembling Manifold

Valve manifold can be disassembled after control module / D-Sub connector is removed.

1. Disassemble tie rod screws on left endplate.

2. Lift latch on right endplate.

3. Pull out right endplate and tie rods.

4. Disassemble tie rod screw on right end plate.

5. Lift latch on Sup/Exh module.

6. Pull out left endplate.

See illustration below.

19

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

§ Assembly Manifold (right endplates as example)

1. Put flat end side of tie rods into right endplate, then attach screws to tie rods.

2. Insert tie rods into valve stations and push to close the gap.

3. Close the latch on right endplate.

4. Push in left endplate. (See Note).

5. Close all latches.

6. Assemble tie rod screws on left endplate and apply torque.

See illustration below.

Note:

Remove this gasket

for IP40 version

before Step 4.

20

Installation & Maintenance Instruction

VR10 / VR15 VALVE ISLAND

Construction & Design is subject to change (A1743-OPM-MX / Rev.004)

Note:

Expansion tie rod kits should be

assembled to the round side and any

gaps closed before inserting into valve

stations.

Other manuals for VR10

3

This manual suits for next models

1

Table of contents

Other Norgren Control Unit manuals

Norgren

Norgren HERION G1/4 User manual

Norgren

Norgren 82 Series User manual

Norgren

Norgren VS18 Manual

Norgren

Norgren FD67 User manual

Norgren

Norgren VP60 Series User manual

Norgren

Norgren VP51 User manual

Norgren

Norgren VR10 Installation and operating instructions

Norgren

Norgren VP23 Series User manual

Norgren

Norgren Prospector A00 5A Series User manual