Page 2 of 4 I&M No. V_6592_CA

©ASCO Valve, Inc. 160 Park Avenue, Florham Park, New Jersey 07932 www.emerson.com

Causes of Improper Operation

• Incorrect Pressure:

• Excessive Leakage: Disassemble valve and clean all parts. If parts are

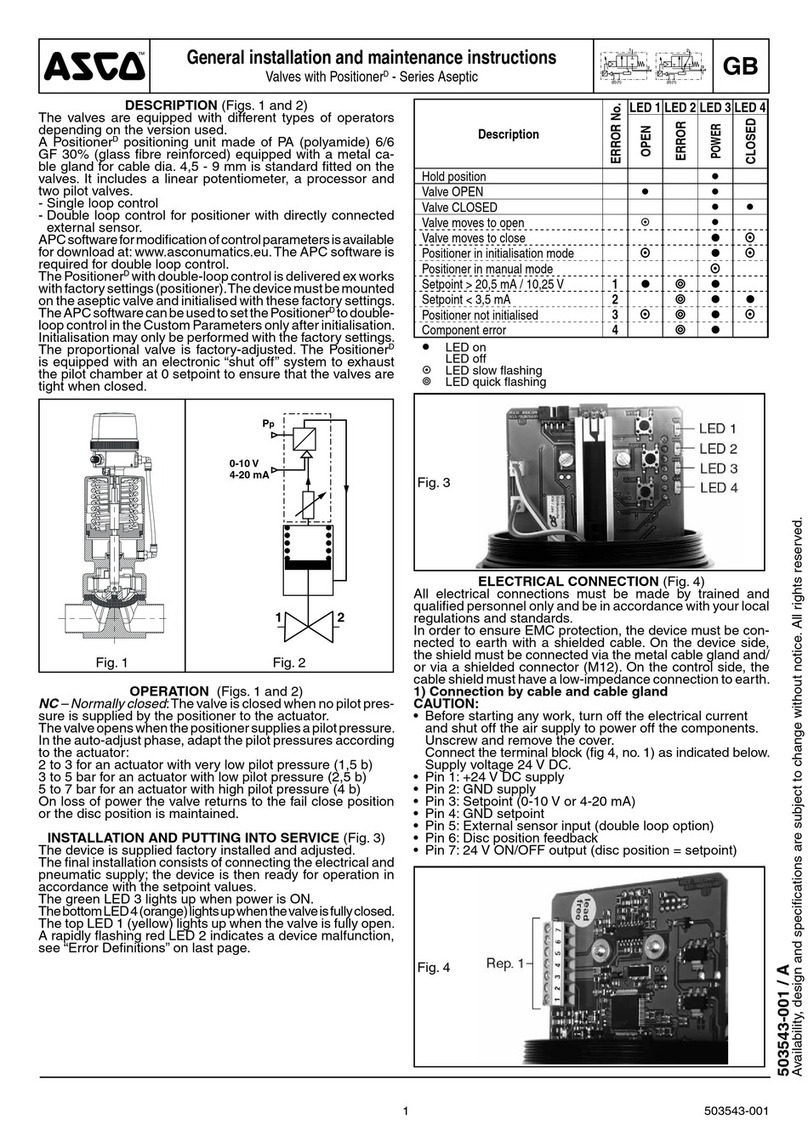

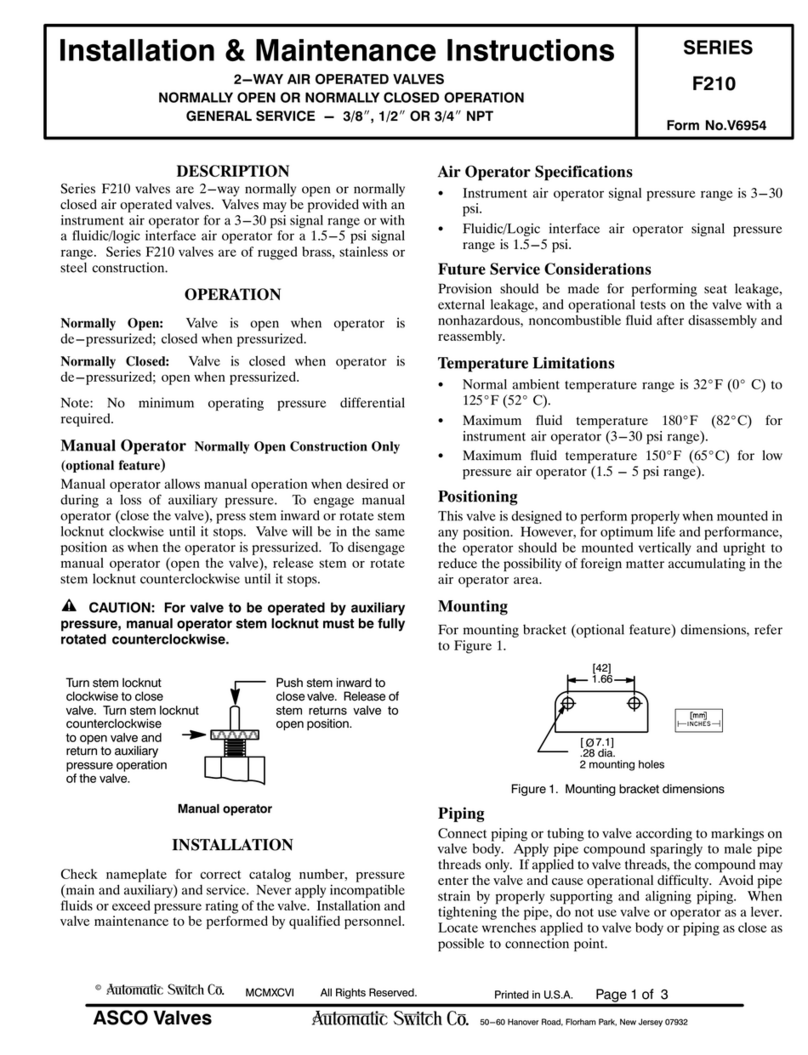

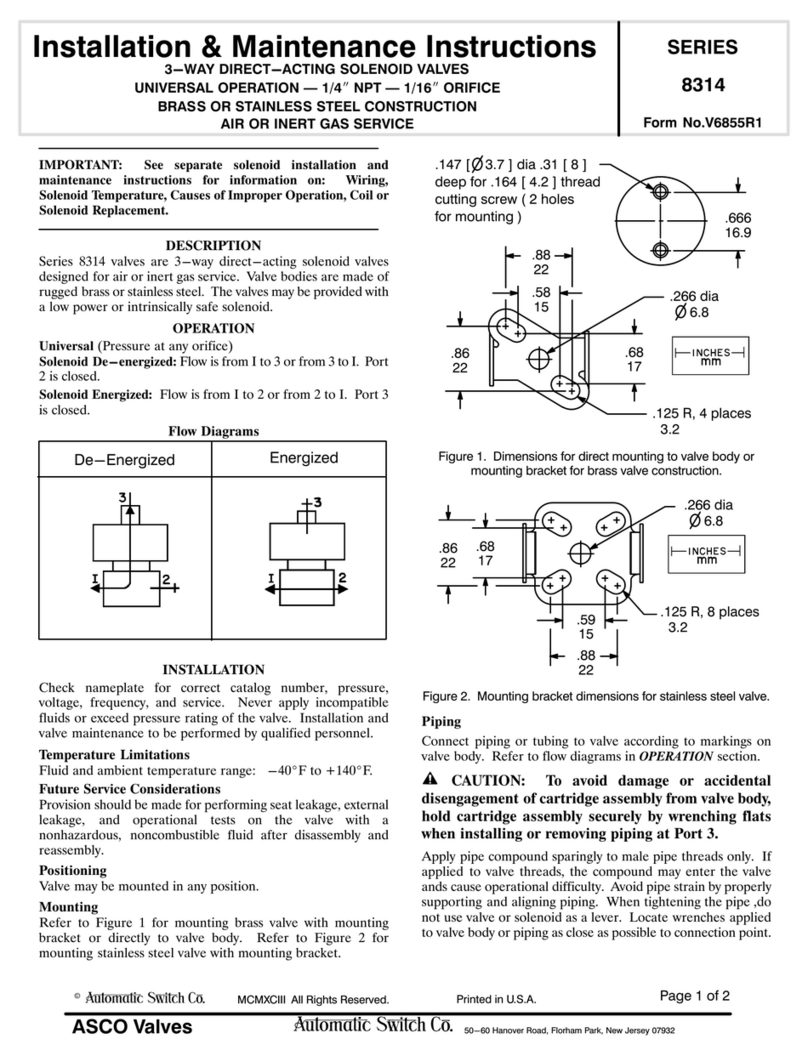

Valve Disassembly (Refer to Figures 1 and 2)

1. Disassemble valve in an orderly fashion. Use exploded views for

2. To remove valve solenoid, see separate solenoid instructions.

3. If the valve being serviced has a manual operator, refer to section

4. Unscrew solenoid base sub-assembly. Remove solenoid base gasket,

core spring and core guide.

5.

self-tapping screw to remove insert from body. Turn screw a few turns

CAUTION: Do not damage center hole (pilot orice) in raised

surface insert. Remove insert by using a pair of pliers to grip the head

of the screw.

ATTENTION: N’endommager pas le trou central (orice

pilote) situé dans la partie haute de la pièce d’insertion. Retirez

la pièce d’insertion en utilisant une pince sur la tête de la vis.

6. Remove three gaskets from insert. Tag each gasket as it is removed so

that they can be reassembled in the same location. Middle and lower

gaskets are the same size. However, the lower gasket is a softer material.

Then remove disc holder sub-assembly, spring cup and disc spring.

7. The solenoid pilot is now completely disassembled.

8. Remove bonnet screws and lockwashers (4) from each end of valve

body. Remove valve bonnets, body passage gaskets, retaining rings,

diaphragm assemblies and body gaskets from each end of the valve

body. These parts are identical.

9.

Valve Reassembly

1.

of parts.

2.

3.

retaining ring, body passage gasket, valve bonnet and bonnet screws.

4.

Nm].

5.

been previously used.

6. Snap upper and middle insert gaskets into grooves of insert. Lower

and the lower corner of the body insert cavity. Middle and lower insert

gaskets are the same size. However, lower gasket is made of a softer

material.

7.

and disc holder sub-assembly) into body cavity, making certain that the

disc holder spring is centered.

8. If the valve being rebuilt has a manual operator, refer to section on

9. Replace solenoid base gasket, core assembly, core spring and core guide,

if present. If the core spring is the internal type as shown in Figure 1, be

end of core spring protrudes from core top. If the core spring is the same

diameter throughout, the end with the closed turns will protrude from the

top of the core.

10.

11. Install solenoid, see separate instructions, and make electrical hookup.

12. Restore line pressure and electrical power supply to valve.

13.

of proper operation.

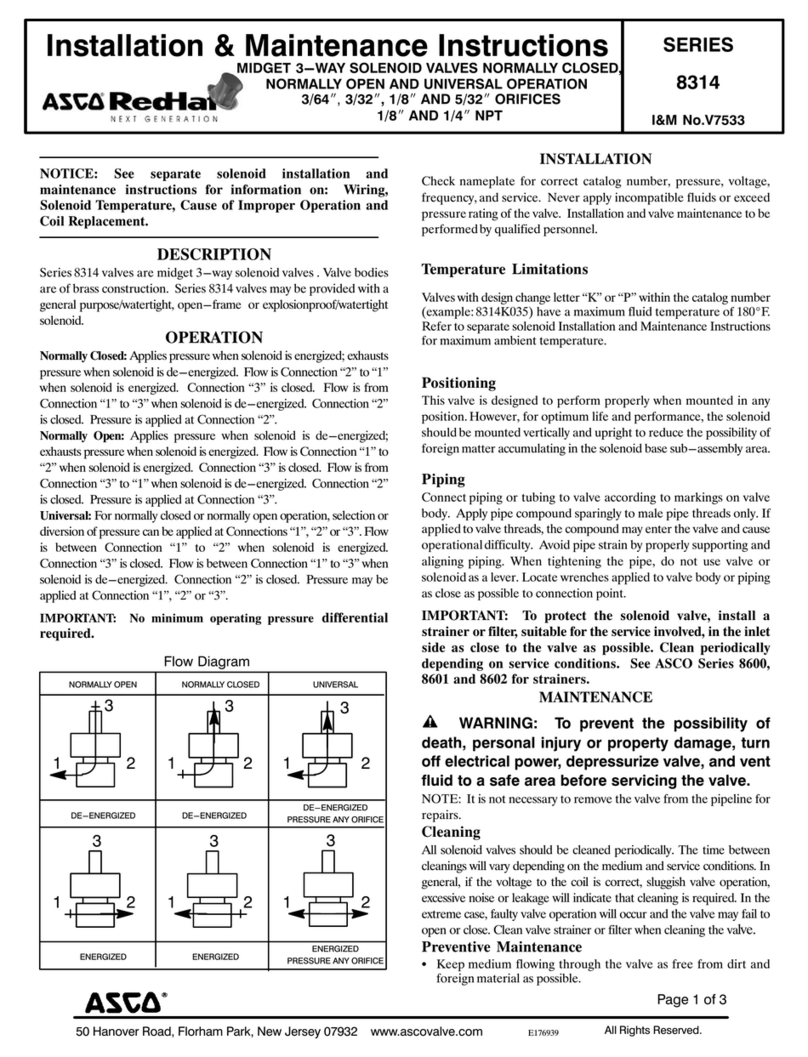

Manual Operator Disassembly

1.

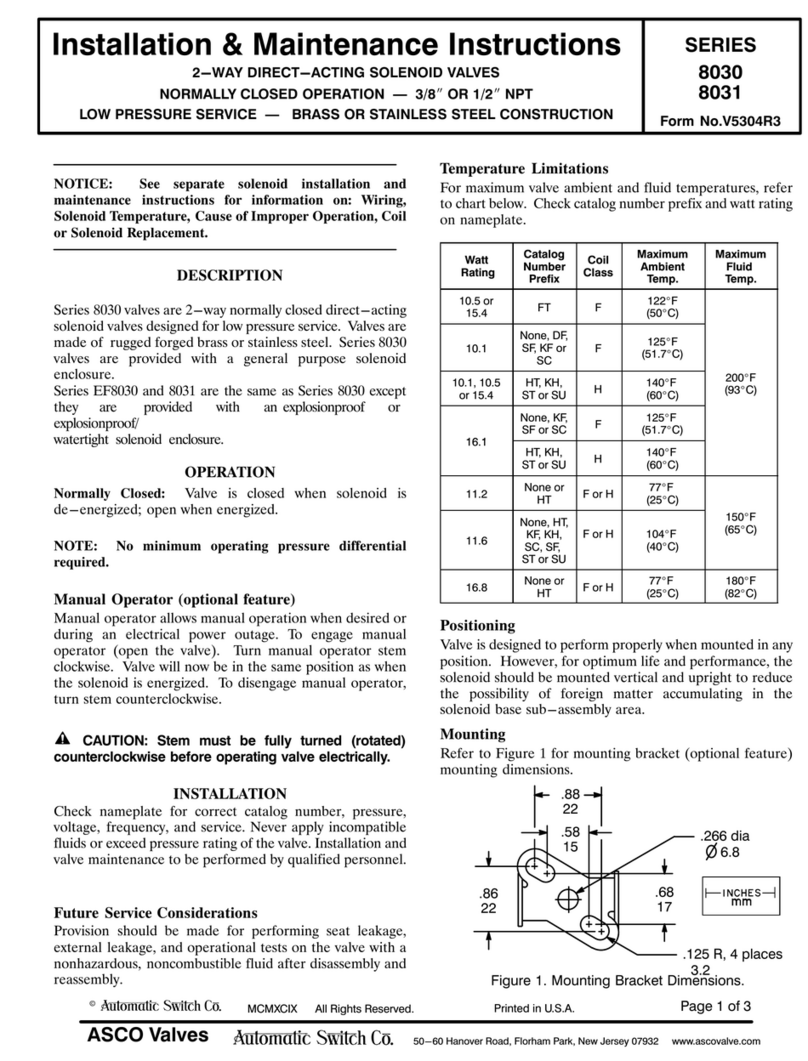

To determine correct manual operator construction, check valve

nameplate for watt rating. Then see Figure 2 for corresponding watt

rating.

2. Unscrew solenoid base sub-assembly. For valves with internal type

core springs, remove core spring, core assembly and solenoid base

gasket.

3. Unscrew manual operator body from main valve body and remove

body gasket.

4. Before removing the stem retainer from the manual operator body, note

the location of the captive spacer on the stem/lever sub-assembly. The

captive spacer will either be on the inside or outside of the fork on the

stem retainer. Location of this spacer is important for reassembly.

5. Remove stem retainer and slip the stem/lever sub-assembly from the

manual operator body. Then remove stem gasket from stem/lever sub-

assembly.

6. For valve with external type core springs, remove core assembly, core

spring, core guide and rider ring (if present). For valve with a watt

rating of 16.8; 6,;6.1; etc., remove disc holder sub-assembly.

7.

Manual Operator Reassembly

1. Reassemble manual operator in reverse order of disassembly. Use

determine construction.

2. Replace body gasket and disc holder sub-assembly, if used.

3. Replace stem gasket on stem/lever sub-assembly.

4.

assembly with stem gasket and stem retainer. On constructions with

an external type core springs, it is necessary to position (preassemble)

the core assembly in the manual operator body as part of the manual

operator body sub-assembly

5. There is a captive spacing washer on the stem/lever sub-assembly.

Referring to the full size template in Figure 2, locate the spacing washer

as follows:

dia.) or valves having a watt rating of 6; 6.1; etc., the spacer must be

located inside the retainer fork.

or valves having a watt rating of 16.8; 10.1; 11.2, etc., the spacer

must be located outside the retainer fork.

6. Install the stem/lever sub-assembly in manual operator body. Determine

the proper location of the spacer and slip the stem retainer in place.

7. For valves, with external type core springs, install core assembly with

core spring, core guide and rider ring (if present) into base of manual

operator body. For valves with internal type core spring, install disc

holder sub-assembly into base of manual operator body.

8.

9.

position that the operator would be in if the valve was to be operated

electrically.

10. Install core assembly, core spring, solenoid base gasket and solenoid

11. Install the solenoid and make electrical hookup

12. Restore line pressure and electrical power supply.

13.

manually a few times to be sure of proper operation.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Rebuild Kit number stamped on the valve nameplate. If the number of

the kit is not visible, order by indicating the number of kits

they are intended.