Norgren VS18 Manual

VS18/VS26 VALVE ADVANTAGE

MAINTENANCE & INSTRUCTION BOOKLET

VS2672926-KG00E

REVISION E

MAY 2007

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

1 CONTENT

1CONTENT ..............................................................................................................................................2

2VS18/VS26-SYSTEM OVERVIEW ...........................................................................................................5

3SAFETY, WARNING ................................................................................................................................6

4TECHNICAL DATA...................................................................................................................................8

4.1 SPECIFICATION ..................................................................................................................................8

4.1.1 Ambient temperature ............................................................................................................................. 8

4.1.2 Medium temperature.............................................................................................................................. 8

4.1.3 Medium.................................................................................................................................................. 8

4.1.4 Air quality............................................................................................................................................... 8

4.2 MATERIALS........................................................................................................................................9

4.3 PNEUMATIC .....................................................................................................................................10

4.3.1 Response times VS valves .................................................................................................................. 10

4.3.2 Flow..................................................................................................................................................... 11

4.3.3 Maximum cycling rate .......................................................................................................................... 11

4.3.4 Minimum impulse on bistable valves ................................................................................................... 11

4.3.5 Important information for 2x2/2 valves................................................................................................. 11

4.4 ELECTRICAL ....................................................................................................................................12

4.4.1 Voltage tolerances ............................................................................................................................... 12

4.4.2 Required performance of power supply unit ........................................................................................ 12

4.4.3 Power supply and precautions............................................................................................................. 12

4.5 COMPLIANCE AND APPROVALS..........................................................................................................13

4.5.1 CE marking.......................................................................................................................................... 13

4.5.2 ATEX (Directive 94/9/EC) for 24V DC only.......................................................................................... 13

4.5.3 ISO standard ....................................................................................................................................... 14

4.5.4 Fieldbus standards .............................................................................................................................. 14

4.5.5 CNOMO standard................................................................................................................................ 14

4.5.6 DIN standard ....................................................................................................................................... 14

4.5.7 UL/CSA approval................................................................................................................................. 14

5INSTALLATION AND MAINTENANCE MECHANICAL.....................................................................................15

5.1 INSTALLATION ..................................................................................................................................15

5.1.1 Tools.................................................................................................................................................... 15

5.1.2 Tightening torque................................................................................................................................. 15

5.1.3 Port identification ................................................................................................................................. 16

5.1.4 Assembly of VS18/VS26 valve islands ................................................................................................ 17

5.1.5 Valve identification labels .................................................................................................................... 21

5.1.6 Internal/external pilot air supply ........................................................................................................... 22

5.1.7 Multi pressure ...................................................................................................................................... 23

5.1.8 DIN-rail assembly ................................................................................................................................ 24

5.1.9 Installation instruction in case of raised vibrations ............................................................................... 25

5.1.10 Sandwich plates................................................................................................................................... 26

5.1.11 Replacement of valves ........................................................................................................................ 28

5.1.12 Replacement of pilot valves................................................................................................................. 29

5.1.13 Manual override set-up kit ................................................................................................................... 30

5.1.14 Blanking plug for base connector hole................................................................................................. 31

5.2 MAINTENANCE .................................................................................................................................32

5.2.1 Lubrication ........................................................................................................................................... 32

5.2.2 Spare parts .......................................................................................................................................... 33

6SINGLE STATION SUB-BASE ..................................................................................................................34

6.1 GENERAL INFORMATION ...................................................................................................................34

6.1.1 24V DC power supply .......................................................................................................................... 34

6.1.2 115V AC power supply ........................................................................................................................ 34

6.1.3 Max current load on valve connectors with 24V DC ............................................................................ 34

6.1.4 Max current load on valve connectors with 115V AC........................................................................... 34

6.2 VARIANT WITH M12 CONNECTOR......................................................................................................35

6.2.1 Pin assignment (acc. VDMA 24571) .................................................................................................... 35

6.3 VARIANT WITH NPTF1/2“ CONDUIT WITH FLYING LEADS .....................................................................36

6.3.1 Wiring information................................................................................................................................ 36

VS2672926-KG00E_05/07 Page 2/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

7MULTIPOLE..........................................................................................................................................37

7.1 GENERAL INFORMATION....................................................................................................................37

7.1.1 24V DC power supply...........................................................................................................................37

7.1.2 115V AC power supply.........................................................................................................................37

7.1.3 Max current load on valve connectors with 24V DC .............................................................................37

7.1.4 Max current load on valve connectors with 115V AC ...........................................................................37

7.2 VARIANTS WITH D-SUB CONNECTORS ...............................................................................................38

7.2.1 D-Sub assembly / Installation of PCB...................................................................................................38

7.2.2 Pin assignment.....................................................................................................................................39

7.3 VARIANT WITH NPTF1” CONDUIT ENTRY WITH TERMINALS ..................................................................42

7.3.1 NPTF1” conduit entry with terminals assembly / Installation of PCB ....................................................42

7.3.2 Pin assignment.....................................................................................................................................44

7.4 VARIANT WITH M23 CONNECTOR ......................................................................................................45

7.4.1 M23 assembly / Installation of PCB......................................................................................................45

7.4.2 Pin assignment.....................................................................................................................................46

8FIELDBUS............................................................................................................................................47

8.1 GENERAL INFORMATION....................................................................................................................47

8.1.1 Power supply and pin assignment ........................................................................................................48

8.1.2 Max. current load on valve connectors.................................................................................................48

8.1.3 Fieldbus assembly / Installation of PCBs (excluding AS-Interface and FD67 bus)...............................49

8.1.4 AS-Interface assembly / Installation of PCBs .......................................................................................50

8.1.5 FD67 bus assembly / Installation of PCB .............................................................................................51

8.2 PROFIBUS DP..................................................................................................................................52

8.2.1 Profibus DP pin assignment .................................................................................................................52

8.2.2 Profibus DP wiring................................................................................................................................53

8.2.3 Profibus DP address and baud rate setting..........................................................................................55

8.2.4 Profibus DP output addressing.............................................................................................................56

8.2.5 Diagnostics...........................................................................................................................................57

8.2.6 Profibus DP LED indicators..................................................................................................................57

8.2.7 Profibus DP commissioning..................................................................................................................57

8.2.8 GSD file................................................................................................................................................58

8.2.9 Profibus DP valve island expansion .....................................................................................................58

8.2.10 More information on Profibus DP .........................................................................................................58

8.3 DEVICENET .....................................................................................................................................59

8.3.1 DeviceNet pin assignment....................................................................................................................59

8.3.2 DeviceNet wiring ..................................................................................................................................59

8.3.3 DeviceNet address and baud rate setting.............................................................................................61

8.3.4 DeviceNet output addressing ...............................................................................................................61

8.3.5 Diagnostics...........................................................................................................................................62

8.3.6 DeviceNet LED indicators ....................................................................................................................62

8.3.7 DeviceNet EDS files and commissioning..............................................................................................63

8.3.8 DeviceNet valve island expansion........................................................................................................64

8.3.9 More information on DeviceNet ............................................................................................................64

8.4 CANOPEN .......................................................................................................................................65

8.4.1 CANopen pin assignment.....................................................................................................................65

8.4.2 CANopen wiring ...................................................................................................................................66

8.4.3 CANopen address and baud rate setting..............................................................................................67

8.4.4 CANopen output addressing ................................................................................................................68

8.4.5 Diagnostics...........................................................................................................................................68

8.4.6 CANopen LED indicators .....................................................................................................................69

8.4.7 CANopen commissioning .....................................................................................................................70

8.4.8 CANopen valve island expansion.........................................................................................................70

8.4.9 More information on CANopen .............................................................................................................70

8.5 INTERBUS-S ....................................................................................................................................71

8.5.1 Interbus-S pin assignment....................................................................................................................71

8.5.2 Interbus-S wiring ..................................................................................................................................72

8.5.3 Interbus-S address and baud rate setting ............................................................................................72

8.5.4 Interbus-S output addressing ...............................................................................................................72

8.5.5 Diagnostics...........................................................................................................................................72

8.5.6 Interbus-S LED indicators ....................................................................................................................73

8.5.7 Interbus-S ID and length codes ............................................................................................................74

8.5.8 Interbus-S commissioning ....................................................................................................................75

8.5.9 Interbus-S valve island expansion........................................................................................................75

8.5.10 More information on Interbus-S ............................................................................................................75

VS2672926-KG00E_05/07 Page 3/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

8.6 AS-INTERFACE ................................................................................................................................76

8.6.1 AS-Interface pin assignment................................................................................................................ 76

8.6.2 AS-Interface wiring .............................................................................................................................. 77

8.6.3 AS-Interface address and baud rate setting ........................................................................................ 77

8.6.4 AS-Interface single slave valve island configurations and settings ...................................................... 78

8.6.5 AS-Interface single slave output addressing........................................................................................ 78

8.6.6 AS-Interface double slave valve island configurations and settings..................................................... 79

8.6.7 AS-Interface double slave output addressing ...................................................................................... 80

8.6.8 Diagnostics .......................................................................................................................................... 81

8.6.9 AS-Interface LED indicators ................................................................................................................ 81

8.6.10 AS-Interface ID and I/O configuration codes ....................................................................................... 82

8.6.11 AS-Interface commissioning ................................................................................................................ 82

8.6.12 AS-Interface valve island expansion.................................................................................................... 82

8.6.13 More information on AS-Interface........................................................................................................ 82

8.7 FD67 BUS .......................................................................................................................................83

8.7.1 FD67 bus pin assignment .................................................................................................................... 83

8.7.2 Wiring termination................................................................................................................................ 84

8.7.3 FD67 bus output addressing................................................................................................................ 84

8.7.4 FD67 bus LED indicators and diagnostics ........................................................................................... 85

8.7.5 FD67 bus commissioning .................................................................................................................... 85

8.7.6 FD67 Profibus GSD file ....................................................................................................................... 85

8.7.7 FD67 DeviceNet EDS file .................................................................................................................... 86

8.7.8 FD67 CANopen EDS file ..................................................................................................................... 86

8.7.9 FD67 valve island expansion ............................................................................................................... 86

8.7.10 More information on FD67 ................................................................................................................... 86

9VALVE ISLAND EXPANSION....................................................................................................................87

9.1 GENERAL INFORMATION ...................................................................................................................87

9.2 ASSEMBLY OF SINGLE ADD-ON STATIONS FOR MULTIPOLE AND FIELDBUS VALVE ISLANDS ....................88

10 USE IN AREAS WITH POTENTIALLY EXPLOSIVE ATMOSPHERE (94/9/EC „ATEX“) – OPERATING MANUAL AND

DECLARATION OF CONFORMITY.............................................................................................................90

10.1 INTENDED USAGE .............................................................................................................................90

10.2 OPERATING MANUAL ATEX .............................................................................................................90

10.2.1 General conditions............................................................................................................................... 90

10.2.2 Installation ........................................................................................................................................... 91

10.2.3 Operating............................................................................................................................................. 91

10.2.4 Failures................................................................................................................................................ 92

10.2.5 Maintenance and repair ....................................................................................................................... 92

10.3 ATEX CONFORMITY .........................................................................................................................93

10.3.1 Operating conditions............................................................................................................................ 93

10.3.2 Labels .................................................................................................................................................. 93

10.3.3 Specific conditions ............................................................................................................................... 94

10.3.4 Declaration of conformity ..................................................................................................................... 94

11 TRANSPORT / STORAGE / PACKAGING ...................................................................................................96

12 REVISION INDEX...................................................................................................................................97

VS2672926-KG00E_05/07 Page 4/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

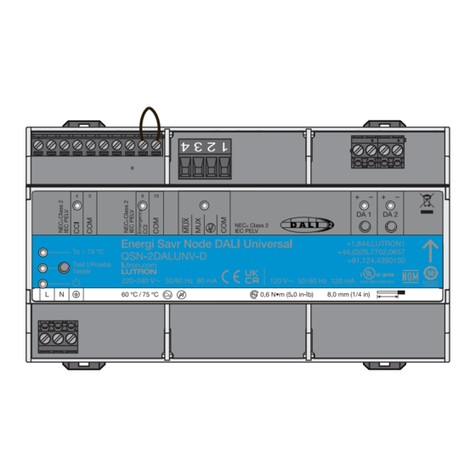

2 VS18/VS26-SYSTEM OVERVIEW

24V DC or 115V AC Multipole

Integrated Fieldbus

Field expandable with single add-on stations

Dual spool technology

VS18G/VS26G Glandless spool and sleeve

for long life

VS18S/VS26S Softseal spool

for high flow

Wide range of accessories

UL and ATEX

Universal PNP/NPN 24V DC Multipole

Please find ordering information of all components in the data sheets 5.4.159 (VS18) and

5.4.160 (VS26).

VS2672926-KG00E_05/07 Page 5/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

3 SAFETY, WARNING

These products are intended for use in industrial compressed air or hydraulic systems only. Do

not use these products where pressures and temperatures can exceed those listed under

‘Technical Data’.

Before using these products with fluids other than those specified, for non-industrial

applications, life-support systems, or other applications not within published specifications,

consult NORGREN. Through misuse, age, or malfunction, components used in fluid power

systems can fail in various modes. The system designer is warned to consider the failure modes

of all component parts used in fluid power systems and to provide adequate safeguards to

prevent personal injury or damage to equipment in the event of such failure.

System designers must provide a warning to end users in the system instructional

manual if protection against a failure mode cannot be adequately provided. System

designers and end users are cautioned to review specific warnings found in instruction sheets

packed and shipped with these products.

Specific warnings:

• Check if classification of the valve island and marking on the item of equipment are able for

case of operation.

• Check technical data, such as operating pressure, voltage level, current type and

temperature, on the product label or in the data sheets for compliance with the existing

operating conditions.

• After removing the packaging, make sure that no contamination enter into the system.

• Check before the installation of the system that no contamination exists in the piping and

valve island.

• Check during installation of the system that gaskets will not become damaged.

• Please consider the information of this operating manual as well as the use conditions and

permissible data, which are on the product labels.

• Adapt to the general rules of technology when selecting and using an item of equipment.

• Take measures to avoid unintentional or improper activation.

• Prior to the first electrical operation, ensure no danger would result from the medium

exhausting from any open ports.

• Consider in case of pressurised systems that lines, valves and other components should not

be removed.

• ATTENTION: There is some risk of injury! The surface of pilot valves could become very

warm in continuous operation.

• ATTENTION: Valves with NO function (normally open) are open without pilot pressure.

During commissioning, protection against exhausted medium has to be provided.

• Leak and strength tests on open and closed valves are admissible until max. 1.5 times the

max. operating pressure. It is not allowed to operate the valve during these tests.

• Never use the valve island as lever arm or a step for climbing.

• Protect the valve island from falling objects.

VS2672926-KG00E_05/07 Page 6/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

• Any fitting position of the valve island is permissible but valves with indicating lights up is

preferred.

• To avoid damaging the product, please make sure that the maximum torque values are not

exceeded (see section 5.1.2).

• Avoid short-circuits and breaks by not deviating from the standard use of connector cables

and cords.

• Order spare parts with the part number indicated on the product labels. (See section 5.2.2

and/or data sheets 5.4.159 (VS18) resp. 5.4.160 (VS26)).

• Do not load the system by bending or torsion.

• Important: Power must be removed from the system while assembling and disassembling

electrical connectors, plugs and cables, valves, sandwich plates and blanking plates.

• Install and use only complete configured and connected valve islands.

• VS18/VS26 Fieldbus valve islands contain electronic devices, which could be damaged

through electrostatic discharge. Therefore electrostatic precautions must be taken.

Specifically, the person assembling or configuring the valve island must be connected to an

earth ground.

• Please refer to section 4.4.3 for information on power supply and earth ground connection of

Multipole and Fieldbus valve islands.

• Use this booklet or the instruction sheets packed with the product for assembling and

installation.

VS2672926-KG00E_05/07 Page 7/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4 TECHNICAL DATA

For more information, please refer to data sheets 5.4.159 (VS18) and 5.4.160 (VS26).

4.1 SPECIFICATION

4.1.1 Ambient temperature

-15°C to +50°C

(Consult our technical service for use below +2°C.)

4.1.2 Medium temperature

-5°C to +50°C

4.1.3 Medium

The valves of these series are intended for use with compressed air only.

The valves must be operated within the pressure range specified in the data sheets 5.4.159

(VS18) and 5.4.160 (VS26).

4.1.4 Air quality

The valves are designed for filtered (40µm), lubricated or non-lubricated compressed air.

(Please find details on oils in section 5.2.1.) If the air supply is lubricated, then lubrication must

be supplied for the life of the product.

VS2672926-KG00E_05/07 Page 8/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.2 MATERIALS

Valve body / sub-bases: Die-cast aluminium

Glandless spool&sleeve (VS**G): Aluminium, hard anodised, teflon coated

Softseal spool (VS**S): Aluminium with HNBR seals

Plastic parts: POM, PA, PPA

Mounting sheets / screws: steel, zinc coated

Springs: stainless steel

Seals: NBR

Sandwich plates: Aluminium bar material, PA

Electrical contacts: brass, tin/gold coated

PCB: Glasepoxy

VS2672926-KG00E_05/07 Page 9/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.3 PNEUMATIC

4.3.1 Response times VS valves

The response measurements are taken according to ISO 12238 standard.

Glandless valves VS**G VS18 VS26

Response

time ON (ms)

Response

time OFF (ms)

Response

time ON (ms)

Response

time OFF (ms)

5/2 Sol/Spring 18 54 24 58

5/2 Sol/Sol 18 18 20 20

5/2 Sol (priority side 14)/Sol 141) 212) 141) 212)

5/3 APB Sol/Sol 24 37 26 52

5/3 COE Sol/Sol 25 49 28 52

Softseal valves VS**S VS18 VS26

Response

time ON (ms)

Response

time OFF (ms)

Response

time ON (ms)

Response

time OFF (ms)

2x2/2 NC Sol/Sol 24 21 29 29

2x2/2 NO Sol/Sol 24 21 29 29

2x2/2 NO/NC Sol/Sol 24 21 29 29

2x3/2 NC Sol/Sol 20 22 32 25

2x3/2 NO Sol/Sol 20 22 32 25

2x3/2 NO/NC Sol/Sol 20 22 32 25

5/2 Sol/Spring 16 42 18 46

5/2 Sol/Sol 14 14 14 14

5/3 APB Sol/Sol 18 40 20 55

5/3 COE Sol/Sol 18 40 19 55

1) ON side 14

2) ON side 12

APB = All ports blocked

COE = Centre open exhaust

NC = Normally closed

NO = Normally open

VS2672926-KG00E_05/07 Page 10/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.3.2 Flow

The flow values are measured at 6 bar inlet pressure and with a pressure drop of 1 bar.

Glandless valves VS**G VS18 VS26

QN

(L/min)

Kv

(m3/h)

Cv (US

Gal/min)

QN

(L/min)

Kv

(m3/h)

Cv (US

Gal/min)

5/2 Sol/Spring 550 0.48 0.56 1‘000 0.87 1.02

5/2 Sol/Sol 550 0.48 0.56 1‘000 0.87 1.02

5/2 Sol (priority side 14)/Sol 550 0.48 0.56 1‘000 0.87 1.02

5/3 APB Sol/Sol 550 0.48 0.56 1‘000 0.87 1.02

5/3 COE Sol/Sol 550 0.48 0.56 1‘000 0.87 1.02

Softseal valves VS**S VS18 VS26

QN

(L/min)

Kv

(m3/h)

Cv (US

Gal/min)

QN

(L/min)

Kv

(m3/h)

Cv (US

Gal/min)

2x2/2 NC Sol/Sol 550 0.46 0.56 1’150 1.00 1.17

2x2/2 NO Sol/Sol 550 0.46 0.56 1’150 1.00 1.17

2x2/2 NO/NC Sol/Sol 550 0.46 0.56 1’150 1.00 1.17

2x3/2 NC Sol/Sol 600 0.52 0.61 1‘250 1.09 1.27

2x3/2 NO Sol/Sol 600 0.52 0.61 1‘250 1.09 1.27

2x3/2 NO/NC Sol/Sol 600 0.52 0.61 1‘250 1.09 1.27

5/2 Sol/Spring 650 0.57 0.66 1‘350 1.18 1.37

5/2 Sol/Sol 650 0.57 0.66 1‘350 1.18 1.37

5/3 APB Sol/Sol 650 0.57 0.66 1‘350 1.18 1.37

5/3 COE Sol/Sol 650 0.57 0.66 1‘350 1.18 1.37

APB = All ports blocked

COE = Centre open exhaust

NC = Normally closed

NO = Normally open

4.3.3 Maximum cycling rate

In practice the cycling rate should be lower than 300 c.p.m. (<5 Hz). The valves should be

switched above 90% (working port) and below 10% (exhausting port) of the supply pressure.

4.3.4 Minimum impulse on bistable valves

The minimum impulse length on 5/2 way bistable valves should correspond at least twice to the

response time (see section 4.3.1).

4.3.5 Important information for 2x2/2 valves

All 2x2/2 functions (NC, NO or NO/NC) have port 1 not connected in neither end position to port

2 or 4. Port 1 is not necessary (except internal pilot air). Supply of compressed air or vacuum

must be feeded to port 3 or 5.

Pay attention to this when configuring the valve island (blanking off canals 3 and 5 in base) !!

VS2672926-KG00E_05/07 Page 11/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.4 ELECTRICAL

4.4.1 Voltage tolerances

Voltage Voltage tolerances

24V DC +/-10%

115V AC -10%/+15%

4.4.2 Required performance of power supply unit

The required performance can be calculated from the maximum number of energized solenoids

at the same time. In case of a Fieldbus valve island the consumption of power of the electronic

has to be considered (see section 8).

4.4.3 Power supply and precautions

All VS18/VS26 24V DC products are designed to be used with a protective extra low voltage

(PELV) power supply (UL Class 2 Supply only).

All VS18/VS26 115V AC products correspond to the protection class I. Connection of the

protective earth (PE) ground is required.

VS2672926-KG00E_05/07 Page 12/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.5 COMPLIANCE AND APPROVALS

The VS18/VS26 products are tested and compliant:

4.5.1 CE marking

Degrees of protection provided by enclosures (IP code):

EN 60529:91+A1:00 (IEC 60529:89 + A1:99)

Low-voltage switchgear and controlgear:

EN 60947-5-1: 97+A1:00+A2:00+A12:00 - Control circuit devices and switching elements

EN 60947-1: 99+A1:00+A2:01 - Electromechanical control circuit devices

Electromagnetic compatibility (EMC directive 89/336/EEC):

EN 61000-6-2: 01 - Immunity for industrial environments

EN 61000-6-4: 01 - Emission standard for industrial environments

Vibrations- and shock test:

DIN EN 60 068-2-6 - Vibration resistance (Test Fc: Vibration (sinusoidal))

DIN EN 60 068-2-27 (30g) - Shock resistance (Test Ea and guidance: Shock)

4.5.2 ATEX (Directive 94/9/EC) for 24V DC only

EN 50021:99 - Electrical apparatus for potentially explosive atmospheres - Type of

protection "n"

EN 13463-1:02 - Non-electrical equipment for potentially explosive atmospheres. Part 1.

Basic methodology and requirements.

EN 50281-1-1:99 - Electrical apparatus for use in the presence of combustible dust - Part 1-1:

Electrical apparatus protected by enclosures - Construction and testing

EN 1127-1:97 - Explosive atmospheres – Explosion prevention and protection – Part 1 :

Basic concepts and methodology.

For more information please refer to section 10.

VS2672926-KG00E_05/07 Page 13/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4.5.3 ISO standard

ISO 15407-2 (size 26mm and 18mm)

4.5.4 Fieldbus standards

Norgren Profibus DP Fieldbus systems conform to

DIN 19245 part 3.

Norgren DeviceNet systems conform to

DeviceNet specification volume 1 release 2 and the Pneumatic Valve Device Profile.

Norgren CANopen Fieldbus systems conform to

CANopen communication profile CiA DS-301 V4.0.

Norgren Interbus-S Fieldbus systems conform to

DIN 19258.

Norgren AS-Interface Fieldbus systems conform to

AS-I V2.11 specification.

For detailed information on Fieldbus protocols please refer to section 8.

4.5.5 CNOMO standard

The M23 19-pin connector fulfils CNOMO standard E03.62.530.N.

For more information on this standard please refer to the CNOMO website www.cnomo.com.

For more information on the M23 19-pin connector please refer to section 7.4.

4.5.6 DIN standard

Colour code of D-Sub connectors according DIN 47100

4.5.7 UL/CSA approval

Investigated to UL 429 - 5th edition & CSA 22.2 No.139 - 1982 for 24V DC electrically operated

valves.

VS2672926-KG00E_05/07 Page 14/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

5 INSTALLATION AND MAINTENANCE MECHANICAL

5.1 INSTALLATION

5.1.1 Tools

VS18:

• Hexagon wrench key 2mm

• Hexagon wrench key 2.5mm

• Socket screw key X10

• Philips screwdriver size 1

• Screwdriver size 1

VS26:

• Hexagon wrench key 3mm

• Socket screw key X10

• Philips screwdriver size 1

• Screwdriver size 1

5.1.2 Tightening torque

To avoid damaging the product, please make sure that the maximum torque values are not

exceeded. The maximum torques are specified in the particular installation instructions.

Valve mounting screws

The valve mounting screws are pressurised. To prevent leakage through the mounting screws,

screws with blue coated thread are used. The specified torques for the blue coated screws

reduce to standard values after first use of the screws. These screws should not be used more

than five times, as good sealing performance can then not be guaranteed.

VS2672926-KG00E_05/07 Page 15/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

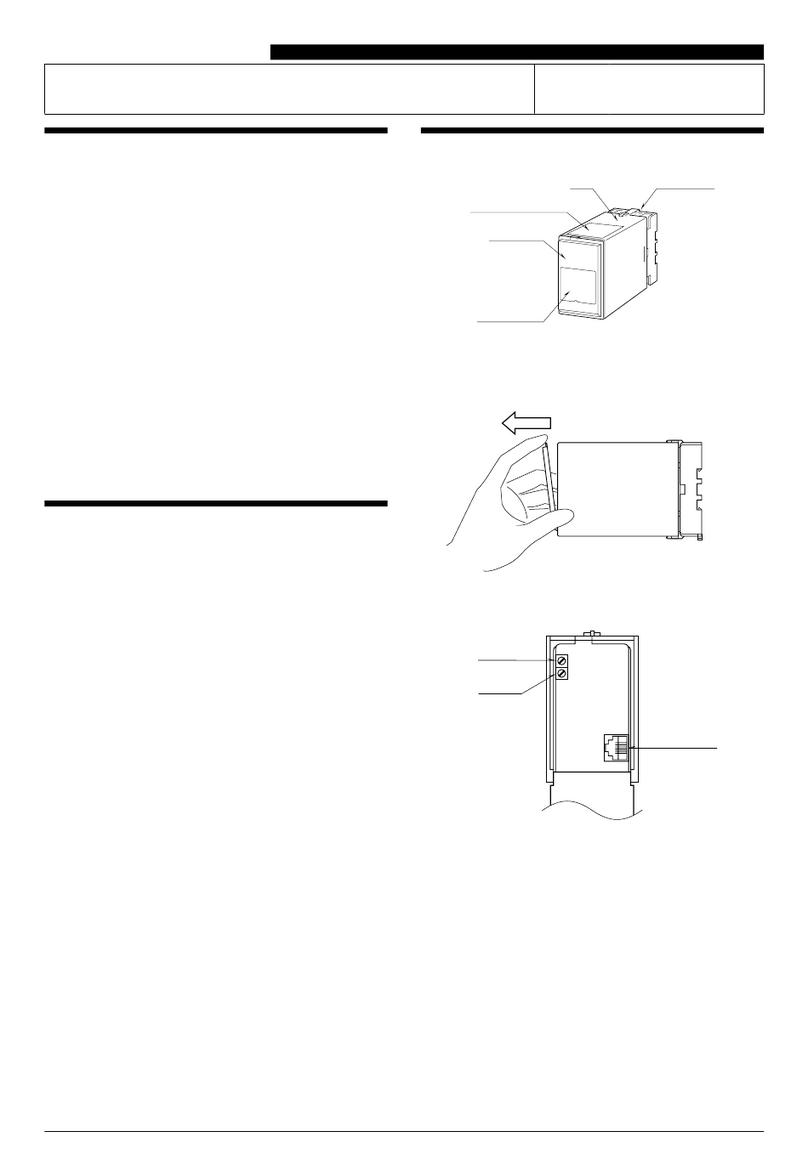

5.1.3 Port identification

On all end plates and modular sub-bases each port is marked as follows:

Function Port/Identification

Main/internal pilot air supply 1

Exhaust 3 + 5

Outlet 2 + 4

External pilot air supply (if used) 12/14

Collected exhaust of pilot valves 82/84

Note:

Never plug port 82/84. Plugging this port will cause valves to malfunction.

port 1 port 82/84

port 12/14

port 2

port 5

port 4

port 3

VS2672926-KG00E_05/07 Page 16/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

5.1.4 Assembly of VS18/VS26 valve islands

Tools:

VS18: Hexagon wrench key 2.5mm

Philips screwdriver size 1

VS26: Hexagon wrench key 3mm

Philips screwdriver size 1

To assemble a complete valve island, make sure you have ordered all necessary components

and the required tools are available.

1. First bolt all modular sub-bases together. Ensure sub-bases are properly aligned and the

gasket is fitted between the sub-bases. Then tighten the mounting screws (two per modular

sub-base) with the specified torque. If you are using a power screwdriver, consider the

maximum speed allowed.

For multi pressure applications, please refer to section 5.1.7.

Note:

When ordering an even number of stations, please ensure the valve island contains a

maximum of two single station modular sub-bases. E.g.: You order an 8-station Multipole

valve island with an 8-station main PCB. The valve island must have at least three double

station modular sub-bases and must have no more than two single station modular sub-

bases.

When ordering an odd number of stations, the single station modular sub-base should be at

the right end of the valve island. In addition, you can use two additional single station

modular sub-bases, for a total of three.

Screw Type

(thread) Valve

seize Tightening

torque in Nm Tightening

torque in Ibs Max. screw driver

speed in r.p.m.

11 M3x10 VS18 0.8 – 0.9 7.08 – 7.96 1100

11 M4x12 VS26 1.0 – 1.1 8.85 – 9.73 1100

VS2672926-KG00E_05/07 Page 17/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

2. Mount the left and right end plate to the modular sub-base. Ensure end plates are properly

aligned and the end plate gasket is fitted. Then tighten the mounting screws (two per end

plate) with the specified torque. If you are using a power screwdriver, consider the maximum

speed allowed.

Screw Type

(thread) Valve

seize Tightening

torque in Nm Tightening

torque in Ibs Max. screw driver

speed in r.p.m.

11 M3x10 VS18 0.8 – 0.9 7.08 – 7.96 1100

11 M4x12 VS26 1.0 – 1.1 8.85 – 9.73 1100

3. Having assembled the base of the valve island, proceed with the electronic components. For

these instructions please refer to following sections:

7.2.1 D-Sub assembly / Installation of PCB

7.3.1 NPTF1” conduit entry with terminals assembly / Installation of PCB

7.4.1 M23 assembly / Installation of PCB

8.1.3 Fieldbus assembly / Installation of PCBs (excluding AS-Interface and FD67 bus)

8.1.4 AS-Interface assembly / Installation of PCBs

8.1.5 FD67 bus assembly / Installation of PCB

VS2672926-KG00E_05/07 Page 18/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

4. Lastly, mount the valves, sandwich plates, blanking plates and/or intermediate

supply/exhaust modules.

Valves:

1. Ensure valve body gasket is fitted on the bottom of the valve. Place valve onto the

modular sub-base aligned to the interface. Use plug-in connection as positioning point.

2. VS26 only: Orientate straight flange of the U-washers towards the outer edge of the

valve.

3. Tighten the valve mounting screws (two per valve) with the specified torque. If you are

using a power screwdriver, consider the maximum speed allowed.

Screw Type

(thread) Valve

seize Tightening

torque in Nm Tightening

torque in Ibs Max. screw driver

speed in r.p.m.

12 M3x40 VS18 1.1 – 1.5 9.73 – 13.27 1100

12 M4x42 VS26 1.2 – 1.6 10.62 – 14.16 1100

VS2672926-KG00E_05/07 Page 19/97

VS18/VS26 MAINTENANCE & INSTRUCTION BOOKLET

Blanking plate and/or intermediate supply/exhaust module (ISEM):

1. Ensure gasket is fitted on the bottom of the blanking plate or ISEM. Place blanking plate

or ISEM onto the modular sub-base aligned to the interface.

2. Tighten valve mounting screws (two per blanking plate/ISEM) with the specified torque.

If you are using a power screwdriver consider the maximum speed allowed.

Screw Type

(thread) Valve

seize Tightening

torque in Nm Tightening

torque in Ibs Max. screw driver

speed in r.p.m.

18 M3x14 VS18 0.8 – 0.9 7.08 – 7.96 1100

18 M4x16 VS26 1.0 – 1.1 8.85 – 9.73 1100

Screw type used with ISEM:

M3x22 VS18 0.8 – 0.9 7.08 – 7.96 1100

M4x25 VS26 1.0 – 1.1 8.85 – 9.73 1100

Sandwich plates: Please refer to section 5.1.10

5. Having assembled the complete valve island, it is possible to mount it on a DIN-rail. For

instructions please refer to section 5.1.8.

VS2672926-KG00E_05/07 Page 20/97

This manual suits for next models

1

Table of contents

Other Norgren Control Unit manuals

Norgren

Norgren FD67 User manual

Norgren

Norgren Prospector A00 5A Series User manual

Norgren

Norgren VR10 Installation and operating instructions

Norgren

Norgren VP60 Series User manual

Norgren

Norgren VP51 User manual

Norgren

Norgren 82 Series User manual

Norgren

Norgren HERION G1/4 User manual

Norgren

Norgren VR10 Instruction Manual

Norgren

Norgren VP23 Series User manual

Popular Control Unit manuals by other brands

Emerson

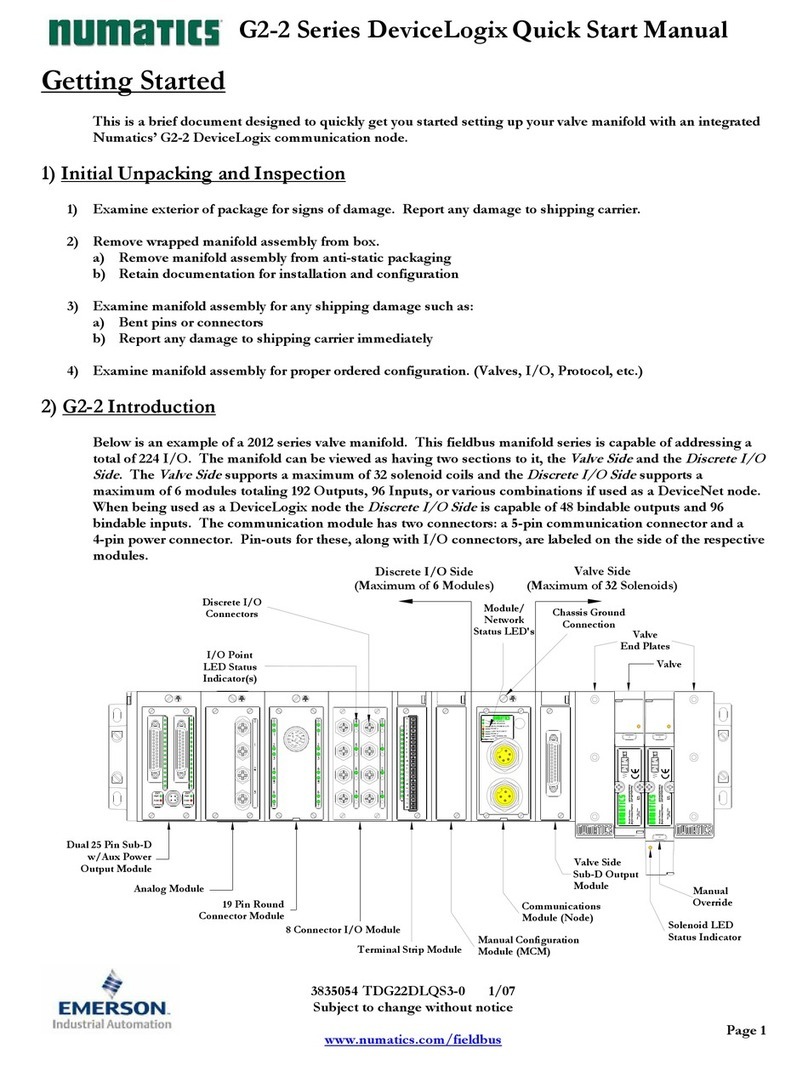

Emerson Numatics DeviceLogix G2-2 Series Quick start manual

Turbonetics

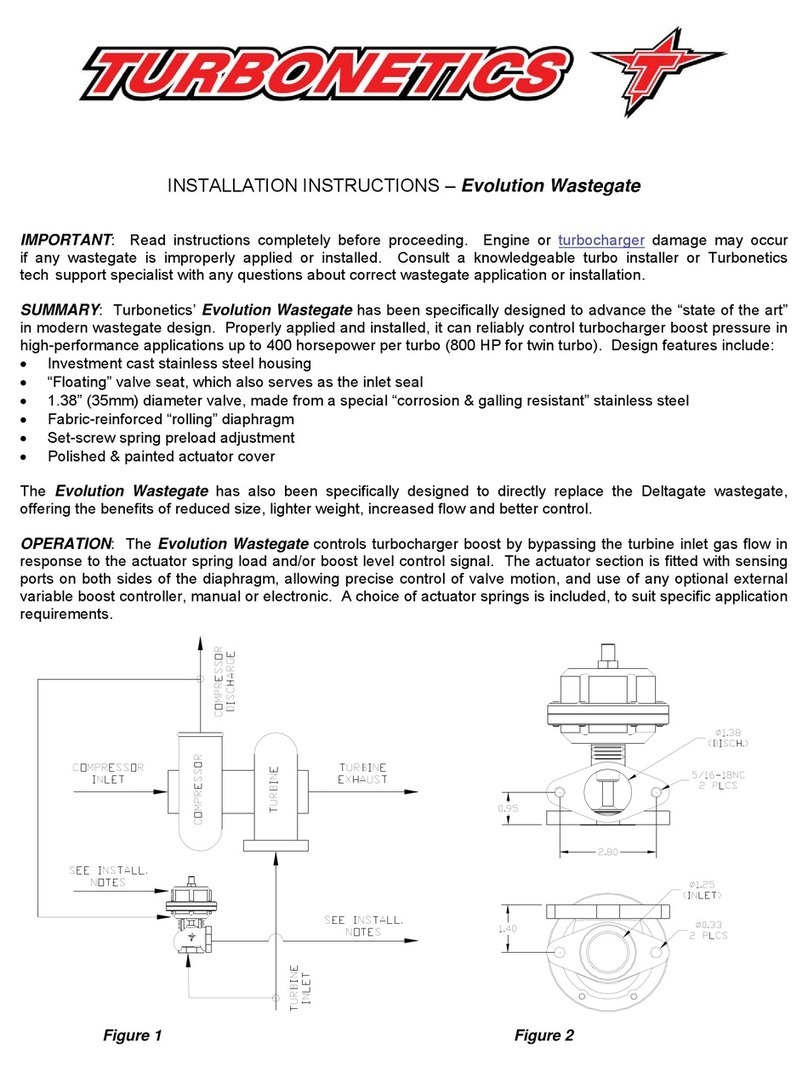

Turbonetics Evolution Wastegate 10780 Installation instructions manual

Simplex

Simplex 2004 Series installation guide

SMA

SMA 1C4-313-001-001 Replacement manual

H3C

H3C MSR Router Comware 5 Series Guide

Festo

Festo CPX-E-1CI manual