norweco HYDRO-KINETIC 1260L User manual

WASTEWATER TREATMENT SYSTEM

MODELS 1260L THROUGH 3020L

INSTALLATION AND OPERATION MANUAL

Hydro-Kinetic®Installation and Operation Instructions

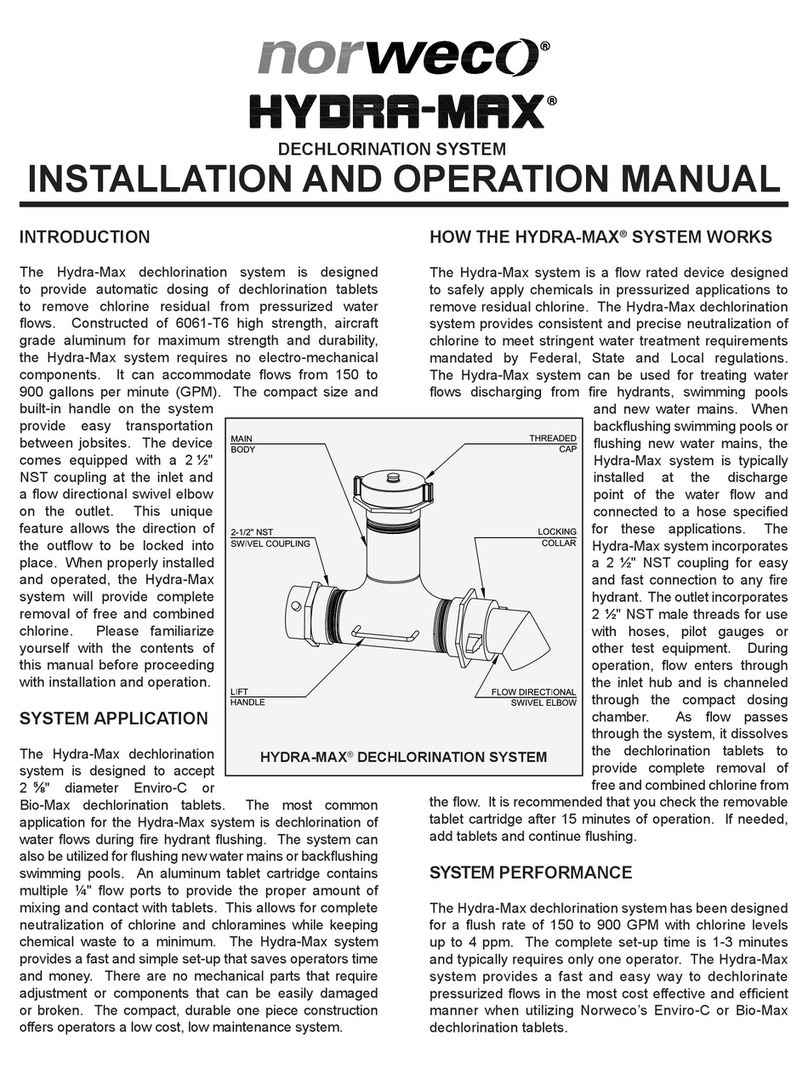

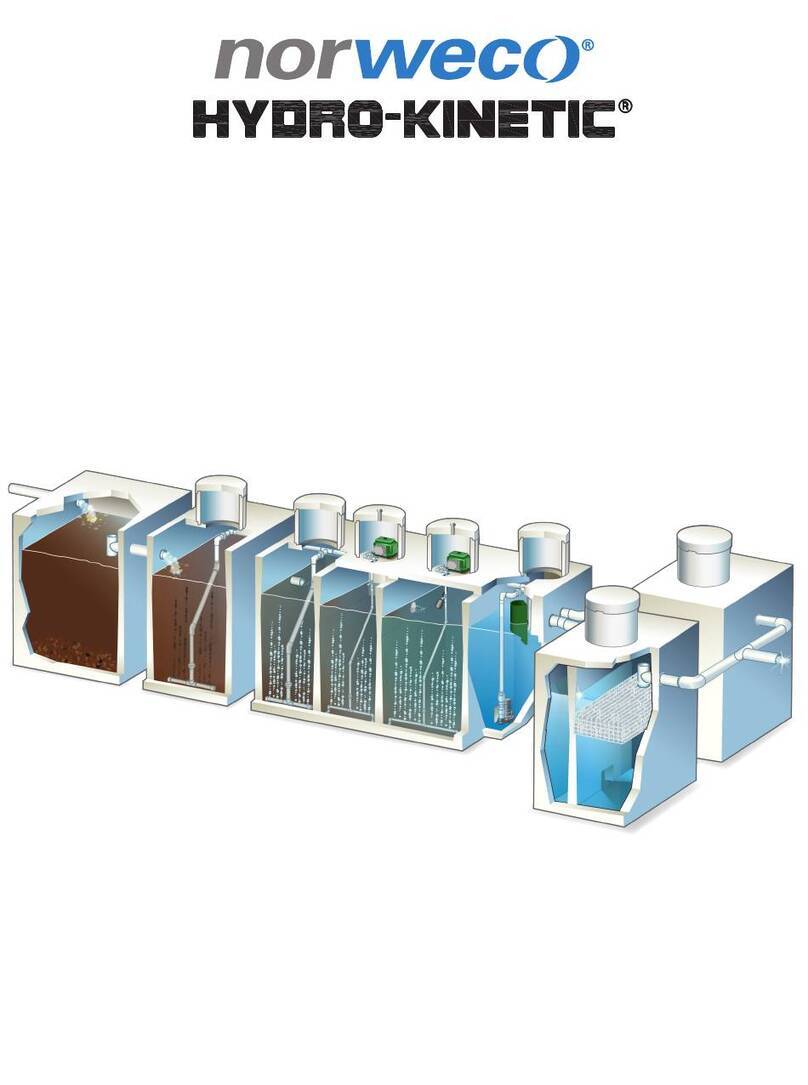

Wastewater enters the pretreatment chamber to precondition the waste before it flows into the anoxic chamber.

Once in the anoxic chamber, facultative anaerobes digest organic matter. Flow then enters the aeration chamber

where aerobic bacteria biologically convert the waste into stable substances and oxidize ammonia into nitrite and

nitrate. Following aeration, liquids flow to the clarification chamber where gravity settles out biologically active

material. A recirculation pump in the clarier transfers a portion of the wastewater back to the anoxic chamber where

nitrogen compounds are converted to harmless nitrogen gas. From the clarier, treated liquids pass through the ow

equalization device and into the disposal system. Euent passes through the Bio-Film Reactor for nal treatment.

The Hydro-Kinetic system is certied to BNQ Standard 3680-600 Class B-IV, D-I, N-I and BNQ Standard 3680-910 Class III,

averaging euent quality of 3.0 mg/L CBOD, 2.0 mg/L TSS, 67% Nitrogen removal and 2,200 CFU/100 ml fecal coliform.

The Hydro-Kinetic system with Phos-4-Fade lter is certied to BNQ Standard 3680-600 Class B-IV, D-I, N-I, P-II and BNQ

Standard 3680-910 Class IV, averaging euent quality of 3.0 mg/L CBOD, 2.0 mg/L TSS, 67% Nitrogen removal, 0.14 mg/L

Total Phosphorus and 2,200 CFU/100 ml fecal coliform. The Hydro-Kinetic system with UV disinfection is certied to BNQ

Standard 3680-600 Class B-IV, D-III, N-I and BNQ Standard 3680-910 Class V, averaging euent quality of 3.0 mg/L CBOD,

2.0 mg/L TSS, 67% Nitrogen removal and 2 CFU/100 ml fecal coliform. The Hydro-Kinetic system with Phos-4-Fade lter

and UV disinfection is certied to BNQ Standard 3680-600 Class B-IV, D-III, N-I, P-II and BNQ Standard 3680-910 Class IV

& V, averaging euent quality of 3.0 mg/L CBOD, 2.0 mg/L TSS, 67% Nitrogen removal, 0.14 mg/L Total Phosphorus and 2

CFU/100 ml fecal coliform.

Before You Start

Installation procedures, equipment and personnel should always comply with applicable safety regulations as well as all federal,

state and local codes. The Hydro-Kinetic system must be installed by an authorized representative of Norweco according to

these instructions to insure safe, reliable and ecient operation. Carefully unpack and inspect the system components.

Make sure you have received all components in good condition. Read all instructions before beginning installation. The

Hydro-Kinetic system components include:

Page 1

1. Service Pro Model 801P Control Center

2. Model A100/A150 Air Pump (with power wire junction box)

3. Alarm Float (with alarm wire junction box)

4. Flow Equalization Device

5. Primary Recirculation Assembly

6. Model SD102/SD103 Recirculation Pump

7. Intermediate Recirculation Assembly

8. Diuser

9. Mixing Bar

10. Mixing Bar Drop Pipe Assembly

11. Diuser Drop Pipe Assembly

12. Primary Air Assembly

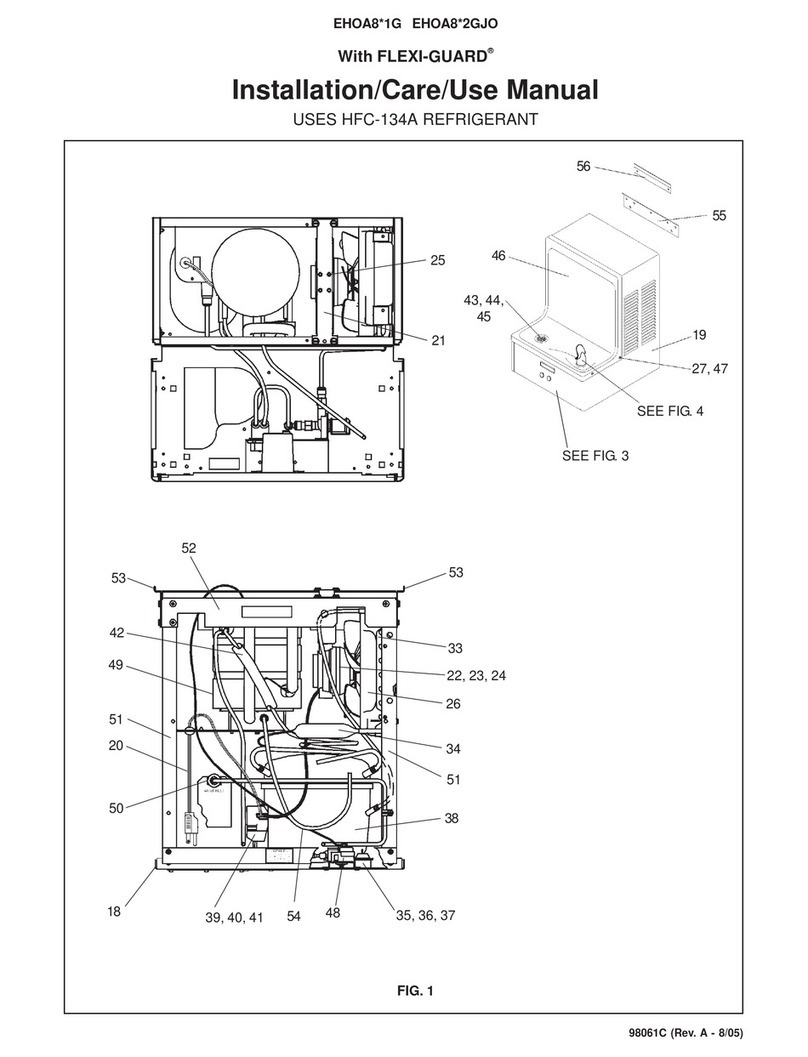

FIGURE 1

4. FLOW

EQUALIZATION

DEVICE

2. AIR PUMP

6. RECIRCULATION

PUMP

12. PRIMARY AIR

ASSEMBLY

(Subassembly A5)

10. MIXING BAR

DROP PIPE

ASSEMBLY

(Subassemblies

S8-S10)

7. INTERMEDIATE

RECIRCULATION ASSEMBLY

(Subassemblies S1-S3)

5. PRIMARY

RECIRCULATION

ASSEMBLY

(Subassemblies S4-S6)

9. MIXING BAR

(Subassembly S7)

1. SERVICE PRO

MODEL 801P

CONTROL CENTER

11. DIFFUSER

DROP PIPE

ASSEMBLY

(Subassemblies A2-A4)

8. DIFFUSER

(Subassembly A1)

3. ALARM FLOAT

PRETREATMENT

CHAMBER ANOXIC

CHAMBER

AERATION

CHAMBER

CLARIFICATION

CHAMBER

S7

S1 S2

S3

S5

S6

S8

S9

S10

A1

A2

A3

A4

A5

S4

Page 2

Pre-Delivery Tank Preparation

The Hydro-Kinetic tank equipment package contains some components that are cast-in the tank during the manufacturing

process, and other components that are installed after the casting process is complete. In the standard two-piece tank, the

only component that needs to be installed prior to delivery is the intermediate recirculation assembly. In a one-piece tank,

the distributor will need to provide a pretreatment outlet tee, an aeration chamber inlet elbow and a Bio-Film Reactor outlet

tee. Norweco recommends assembling all of these components, as well as the Bio-Film Reactor elements, before the tank

is delivered to the installation site. Install components according to the following steps:

1. For a one-piece tank, solvent weld the 4" Schedule 40 PVC pretreatment outlet tee to the coupling that was cast-in the

outlet of the pretreatment chamber (distributor to provide). Solvent weld the 4" Schedule 40 PVC aeration chamber

transfer elbow into the coupling cast-in the inlet of the aeration chamber (distributor to provide).

2. For all systems, begin in the anoxic chamber and solvent weld subassembly S1 into the coupling that was cast-in the

wall between the anoxic and aeration chambers. The elbow should be oriented as shown in Figure 2, with the short

stub of pipe parallel to the oor and ceiling of the tank.

3. Solvent weld subassembly S2 into the aeration chamber side of the same cast-in coupling. See Figure 2.

4. Starting in the aeration chamber, pass subassembly S3 through the wall into the clarication chamber. Solvent weld

the coupling on subassembly S2 to subassembly S3. See Figure 2.

5. Place the Bio-Film Reactor elements into the media chamber of the Bio-Film Reactor tank. They will rest on the

support rib cast into the media chamber. The Bio-Film Reactor elements should be installed with the media service

hatch oriented toward the middle of the tank and facing up. See Figure 3.

6. Using the universal tool, rotate the two slide locks on each Bio-Film Reactor element so that they lock into the recesses

cast into the tank.

Tank Delivery and Setting

1. When installing a Hydro-Kinetic system, rst check the length, width and depth of the excavation. Insure the excavation

is long enough to allow at least 2' between the treatment tank and the Bio-Film Reactor for installation of the interconnect

plumbing and backll between the tanks. Cut a 4" Schedule 40 PVC pipe (distributor to provide) 6" longer than the

distance between the tanks for the interconnect plumbing. Insert the interconnect pipe into the inlet of the Bio-Film

Reactor tank prior to tank placement. This allows the interconnect pipe to be backed straight out, and solvent welded

into the cast-in outlet coupling of the clarication chamber when the tank is set. The excavation should have sucient

overdig to allow for a minimum of 6" clearance around the entire perimeter of the system. Additional overdig will be

required on deep installations or where unstable soil conditions exist. Safe working conditions must be established

and maintained during the entire installation procedure.

2. Prepare the excavation to the appropriate depth based on the elevation of the building sewer line. Concrete systems

should have a maximum burial depth of 42" below grade to top of the tank. HDPE systems should have a maximum

burial depth of 36½" below grade to top of the tank. Allow ⅛" of fall per foot from the building to the system. Fall

through the system is 5" from inlet invert to outlet invert. Therefore, the outlet line from the system must be installed

5" lower than the inlet sewer line. The bottom of the excavation must be level and smooth. A 4" layer of gravel, sand

or ne crushed stone should be installed and leveled to within ¼" from side to side and end to end.

FIGURE 3

BIO-FILM REACTOR

ELEMENTS

INLET

ROTATE SLIDE

LOCKS

OUTLET

BIO-FILM REACTOR

TANK

INFLUENT

CHAMBER

MEDIA

CHAMBER

S1 S2

CAST-IN

COUPLING

ANOXIC

CHAMBER

FIGURE 2

CLARIFICATION

CHAMBER

S3

AERATION

CHAMBER

Page 3

3. Using extreme caution, place the treatment tank into the excavation. Place the Bio-Film Reactor in the excavation

allowing at least 2' between the treatment tank and the Bio-Film Reactor tank. Insure tanks are installed square and

level.

4. Connect the building sewer line to the pretreatment chamber inlet. The inlet line must be laid continuously and

unspliced from the tank to undisturbed earth beyond the limits of the tank excavation.

5. Back the interconnect pipe out of the Bio-Film Reactor tank and solvent weld the pipe to the outlet coupling of the

clarication chamber. Then, connect the discharge sewer line to the Bio-Film Reactor tank outlet continuously and

unspliced from the tank to undisturbed earth beyond the limits of the tank excavation. If using a one-piece tank, insert

discharge sewer line through tank outlet seal, leaving 4" to 6" protruding inside the tank. Solvent weld the 4" Schedule

40 PVC outlet tee (distributor to provide) to the discharge sewer line.

6. Install risers as required to bring the access covers to grade.

Plant Wiring and Control Center Installation

1. Electrical work must be performed in accordance with the latest edition of the National Electrical Code as well as

applicable local codes.

2. All electrical service cable used with the Hydro-Kinetic system must be UL and CSA approved, type UF, #14/2 AWG

minimum and must have a full-size center ground. Larger cable is required if the length of the underground service is

greater than 80 feet. Consult your electrician for details.

3. An approved cable must be installed from the air pump to the junction box provided for connection to the control

center. If installing the air pump in a location other than the aeration chamber riser, insure the air line is no more

than 75' in length and the air pump is protected from the elements in a clean, dry, well-ventilated area and proceed

to step 6.

4. Inspect the power cable entrance in the side of the aeration riser. Remove any sharp edges or ash. Insert the free

end of the power cable through the shorter segment of a pre-formed ½" conduit ell (2' by 1'), then into the power cable

entrance of the aeration riser. Guide the power cable into the riser. Pull enough cable through the riser to reach 36"

above the riser top. Coil and secure the cable in the aeration riser so that it will not hang down into the tank.

5. Lay the conduit ell with cable directly across the top and down the tank side. Do not allow the power cable to be laid

across the end of the tank or any removable access cover. Seal the connection between the conduit and the aeration

riser with mortar or approved sealant.

6. A second underground cable must be installed unspliced from the Service Pro control center into the clarication

chamber riser to supply power to the recirculation pump.

7. Inspect the power cable entrance in the side of the concrete clarication riser. Remove any sharp edges or ash.

Insert the free end of the power cable through the shorter segment of a pre-formed ½" conduit ell (2' by 1'), then into

the power cable entrance of the clarication riser. Guide the power cable into the riser. Pull enough cable through the

riser to reach 36" above the riser top. Coil and secure the cable in the clarication riser so that it will not hang down

into the tank.

8. Lay the conduit ell with cable directly across the top and down the tank side. Do not allow the power cable to be

laid across the end of the tank or any removable access cover. Seal the connection between the conduit and the

clarication riser with mortar or approved sealant.

9. Two alarm leads must be installed from the air pump pressure switch to the Service Pro control center. The alarm

leads should be #16 AWG minimum and installed in conduit where contact with concrete may occur. IMPORTANT:

Alarm leads and power leads must always be installed in separate conduits.

10. Two alarm leads must be installed from the high water oat switch to the Service Pro control center. The alarm leads

should be #16 AWG minimum and installed in conduit where contact with concrete may occur. IMPORTANT: Alarm

leads and power leads must always be installed in separate conduits. If the air pump will be installed in the aeration

riser, the high water and air pump alarm leads should be installed in the same conduit. Properly seal the conduit

opening in the riser with mortar or approved sealant.

11. Check the excavation and sewer line trenches to be sure they are free of debris, rocks and any sharp or abrasive

objects that could damage electrical cables or alarm leads during backll or settling.

Page 4

12. Uncoil the electrical service cables and alarm leads into the excavation and inuent sewer line trench. Leave sucient

slack in the cables so they will not be stressed or pulled tight during backll or settling.

13. Always encase the electrical cables and alarm leads in conduit any time they are above nished grade. Route the

conduits and cables as directly as possible to the control center mounting location.

Required Prior to Backlling

1. For installations where the air pump will not be located in the aeration riser, install a ¾" Schedule 40 PVC air line from

the air pump to the system. The air line should be buried in a trench at a recommended depth of at least 12 inches.

Protect the air line in a casing pipe if heavy loading is anticipated. The air line must be run into the aeration riser and

the opening in the riser sealed with mortar or approved sealant.

2. On the Bio-Film Reactor elements, use the universal tool to insure each of the slide locks are rotated until they are in

the furthest extension point possible.

Backlling

1. The system should be backlled immediately after sewer lines and underground electrical cables are installed. Fine,

loose earth should be used to backll the tank excavation and sewer line trenches. Be sure it is completely free of

rocks, large clumps of earth and construction debris. Use ne granular material when backlling around electrical

cables and conduits. The underground electrical cables should have at least two feet of earth cover. If the proposed

nished grade will not permit this coverage, the cables should be installed in approved conduit from the tank to the

building foundation. Backll evenly around the entire perimeter of the tank rather than all at once on each side. Take

care to completely ll in the cavity beneath the hopper at the bottom of the clarier end wall.

2. Final grading should be 6" below the top of each access cover and should slope away from the tank so surface runo

will drain away from the treatment system. Use extreme care in backlling. Do not allow dirt or mud to enter any part

of the treatment system or sewer lines. If dirt or mud enters any portion of the system, it must be removed to insure

proper system operation. Removing the dirt or mud may require repeated ushing and tank pumping.

3. Immediately after backlling, ll each chamber of the

treatment system with water to the outlet invert. The

water must be free of leaves, mud, grit or any other

materials that might interfere with system operation.

Air Pump and Piping Installation

1. Remove all packaging from the plumbing assemblies

labeled "AIR". Attach diuser bar A1 to subassembly

A2 at union as shown in Figure 4. Securely tighten

union by hand.

2. Solvent weld subassembly A2 to subassembly

A3 as shown in Figure 4. Insure red arrows are

aligned.

3. Solvent weld subassembly A3 to subassembly

A4 as shown in Figure 4. Insure blue arrows are

aligned.

4. Install this entire assembly into aeration chamber by

bending the exible tubing. Lower assembly into the

tank until the diuser bar contacts both the oor and

side wall of the tank as shown in Figure 4.

5. Remove air pump and components from carton. If

the air pump will be installed in the aeration chamber

riser, install a concrete support base for air pump.

6. Install the air pump in the aeration chamber riser on

the support base (or in a clean, dry, well-ventilated

area protected from the elements no more than

75' from the tank). Attach subassembly A4 to

subassembly A5 at union as shown in Figure 4.

Securely tighten union by hand.

FIGURE 4

FIGURE 5

AERATION

CHAMBER

A5

A4

A3

A1

A2

PRETREATMENT

CHAMBER

CLARIFICATION

CHAMBER

AERATION

CHAMBER

ANOXIC

CHAMBER

Page 5

7. To wire the air pump female electrical connector, unscrew

the three captive stainless steel screws from the face of the

female connector. They will stay in the body of the receptacle.

Lift out the rigid internal receptacle body. Unscrew the

compression nut on the strain relief connector. Insert

the electrical service cable through the compression nut,

compression ring and neoprene grommet. Strip the outer

insulation back 1¼" on the underground electrical service

cable and expose the three individual leads. Use extreme

care to be sure the insulation jackets on the individual black

and white leads are not scarred or damaged while stripping

the outer jacket.

8. Strip o the insulation jackets 7

/16" from the ends of the

individual black and white leads. Insert the black lead into

the hole adjacent to the brass-colored screw and tighten the

screw securely. Insert the white lead into the hole adjacent

to the silver-colored screw and tighten the screw securely.

Insert the bare copper ground lead into the hole that is

adjacent to the green-colored screw and tighten the screw

securely. Align the insert key on the receptacle body with the

keyway molded into the rubber sleeve. Press the receptacle body into the sleeve and tighten the three stainless steel

screws on the face of the connector. Press the grommet into the electrical connector and tighten the compression nut.

Recirculation Pump and Piping Installation

In the clarication chamber:

1. Remove all packaging from the

plumbing assemblies labeled

"SLUDGE". Solvent weld subassembly

S3 to subassembly S4 in the

clarication chamber (S3 was installed

with the Tank Equipment Package). Be

sure the union is facing horizontally as

shown in Figure 6.

2. Thread subassembly S5 into the pump

discharge as shown in Figure 7.

3. Solvent weld the coupling on

subassembly S5 to subassembly S6.

See Figure 7.

4. Attach pump cord to pump discharge

assembly (S5-S6) using cable ties

provided.

5. Use discharge assembly to lower

pump into the clarication chamber

until pump rests on the oor of the

hopper as shown in Figure 7. Attach

subassembly S4 to subassembly S6 at

union. Securely tighten union by hand.

In the anoxic chamber:

6. Attach subassembly S7 to subassembly S8 at union as shown in Figure 7. Securely tighten union by hand.

7. Solvent weld subassembly S8 to subassembly S9 as shown in Figure 7. Insure yellow arrows are aligned.

8. Solvent weld subassembly S9 to subassembly S10 as shown in Figure 7. Insure green arrows are aligned.

9. Bend mixing bar assembly at exible tubing and lower into anoxic chamber until mixing bar is positioned as shown in

Figure 7. Attach subassembly S10 to subassembly S1 at union. Securely tighten union by hand.

FIGURE 6

S5

FIGURE 7

CLARIFICATION

CHAMBER

ANOXIC

CHAMBER CLARIFICATION

CHAMBER

AERATION

CHAMBER

S6

S5

S3

S2

S1

S10

S9

S8

S7

S4

S3

S4

CLARIFICATION

CHAMBER

Page 6

FIGURE 8

10. Wire the recirculation pump female electrical connector. Unscrew

the three captive stainless steel screws from the face of the female

connector. They will stay in the body of the receptacle. Lift out the

rigid internal receptacle body. Unscrew the compression nut on the

strain relief connector. Insert the electrical service cable through the

compression nut, compression ring and neoprene grommet. Strip the

outer insulation back 1¼" on the underground electrical service cable

and expose the three individual leads. Use extreme care to insure

the insulation jackets on the individual black and white leads are not

scarred or damaged while stripping the outer jacket.

11. Strip o the insulation jackets 7

/16" from the ends of the individual black

and white leads. Insert the black lead into the hole adjacent to the

brass-colored screw and tighten the screw securely. Insert the white

lead into the hole adjacent to the silver-colored screw and tighten the

screw securely. Insert the bare copper ground lead into the hole that

is adjacent to the green-colored screw and tighten the screw securely.

Align the insert key on the receptacle body with the keyway molded

into the rubber sleeve. Press the receptacle body into the sleeve and

tighten the three stainless steel screws on the face of the connector.

Press the neoprene grommet into the electrical connector and tighten the compression nut.

12. Plug the male connector on the recirculation pump power cord into the female connector.

13. Install the ow equalization device by sliding it into the tank receiving ange in the clarication chamber as shown in

Figure 8. Use the universal tool to insure the device is completely seated in the ange.

Completing the Installation

1. The control center should be wired for operation when the tank and underground electrical cables are installed. The

control center should be located so that the red warning light can be seen and the audible alarm heard. The mounting

location should minimize exposure to direct sunlight, freezing rain or conditions that might prevent routine inspection

or access. The control center should always be mounted out of the reach of children.

2. Remove the cover from the alarm wire junction box connected to the oat switch. Solvent weld the junction box to the

conduit containing the alarm leads, located in the aeration chamber riser.

3. Reference Figure 9 for all wiring instructions. The black and white alarm wires contained in the junction box are

provided to connect the oat switch to the control center. Connect the black wire in the junction box to either alarm

lead from the panel, and secure with a wire nut connector. Connect the white wire in the junction box to the remaining

alarm lead from the panel, and secure with a wire nut connector.

4. If the air pump is installed in the aeration chamber riser, solvent weld the conduit connection for the pressure switch

alarm cable to the junction box. Connect the black wire in the pressure switch cable to either alarm lead from the

panel, and secure with a wire nut connector. Connect the white wire in the pressure switch cable to the remaining

alarm lead from the panel, and secure with a wire nut connector.

5. Reinstall and secure the cover on the alarm wire junction box. Plug any unused junction box openings.

6. Proceed to the control center. Detach the cover from the control center enclosure and remove the insert from the

mounting posts. Set the control center insert aside. Remove the knockouts in the bottom of the enclosure and install a

sealed conduit connector (distributor to provide) in each opening. Exposed wiring to or from the control center should

always be encased in conduit. Mount the control center securely using masonry nails, wood screws or common nails

as appropriate.

7. Use a dedicated 115 VAC, single-phase circuit at the main electrical service panel. A 15 amp circuit breaker is

recommended (10 amp minimum). CAUTION: MAKE SURE THIS CIRCUIT IS DE-ENERGIZED. CHECK IT

WITH AN ELECTRICIAN’S TEST LIGHT BEFORE PROCEEDING. REMEMBER THAT OTHER CIRCUITS IN THE

SERVICE PANEL MAY REMAIN ENERGIZED AS YOU ARE WORKING. USE ONLY TOOLS WITH INSULATED

HANDLES, STAND IN A DRY LOCATION AND WORK WITH EXTREME CARE.

8. Open the black electrical insulator on the back of the control center insert for access to power and alarm wiring

connections.

9. Install a #14/2 AWG minimum cable with full-size center ground from the control center to the power wire junction box

provided for connection to the control center.

FLOW

EQUALIZATION

DEVICE

INSURE DEVICE

IS COMPLETELY

SEATED IN FLANGE

RECEIVING

FLANGE

UNIVERSALUNIVERSAL

TOOLTOOL

CLARIFICATION

CHAMBER

Page 7

10. Wire from the dedicated circuit breaker in the main service panel to the power wire junction box. Use at least #14 AWG

black copper wire. Connect the black wire from the main service panel to the black wire in the air pump power cable

and the black wire to the control center. Secure with a wire nut connector.

11. Wire from the neutral in the main service panel to the junction box. Use at least #14 AWG white copper wire. Connect

the white wire from the main service panel to the white wire from the air pump power cable and the white wire to the

control center. Secure with a wire nut connector.

12. Connect the ground wire from the main electrical service panel to the non-insulated ground lead from the air pump and

the ground wire to the control center. Secure with a wire nut connector. IMPORTANT: Never allow the white neutral

leads and the ground leads to be spliced together.

13. Install the cover on the junction box and proceed to the control center.

14. Connect the black wire from the junction box to the black wire on the control center. Secure with a wire nut connector.

15. Connect the black lead of the underground electrical cable from the recirculation pump to the red wire on the control

center. Secure with a wire nut connector.

16. Connect the white wire from the junction box to the white wire from the recirculation pump and white wire on the control

center. Secure with a wire nut connector.

17. Connect the ground wire from the junction box to the non-insulated ground lead from the recirculation pump and the

green wire on the control center. Secure with a wire nut connector. IMPORTANT: Never allow the white neutral leads

and the ground leads to be spliced together.

18. An auxiliary alarm input (AUX1) is available for connection of optional equipment such as an ultraviolet disinfection

system, chemical detection system or euent pump system. Refer to the Alarm Input section in the Service Pro Model

801P Installation and Operation Instructions for details regarding the connection of auxiliary equipment.

19. Connect the alarm leads from the high water oat switch to the AUX2 RELAY terminals on the control center.

20. Connect the alarm leads from the air pump pressure switch to the AUX3 RELAY terminals on the control center.

21. If the remote monitoring features of the control center will be utilized, run the telephone or network cable to the bottom

of the control center enclosure. IMPORTANT: Never install the communication cable in a conduit with power lines.

22. Place the communication cable in the electrical grommet provided. The grommet snaps into the control center

enclosure. Crimp the appropriate phone or network connector on the end of the communication cable. Plug the

connector into the jack on the control center insert. Connect the other end to the telephone or network system.

FIGURE 9

Page 8

23. Carefully form all wiring neatly into the lower part of the control center. Do not allow the wires to make contact with

other electrical components in the control center. The conduit openings in the enclosure must now be sealed using

expanding foam sealant (available from Norweco).

24. Close the black electrical insulator and snap the control center insert into position. Reinstall and close the control

center cover. Secure it with the Norweco tamper evident seal.

25. Clearly label the dedicated circuit used for the Hydro-Kinetic system on the door of the main service panel. Replace

the service panel deadfront and enclosure cover.

Final Check and System Startup

1. Place the dedicated circuit breaker for the Hydro-Kinetic system in the main service panel in the "on" position.

2. To commission the telemetry system, rst insure the phone/network cable is properly installed. Place the control

center power switch in the "o" position. While holding in the reset button, place the power switch in the "on" position.

Continue to hold the reset button for 5 seconds. Release the reset button and allow the telemetry system up to 60

seconds to call out and complete the commissioning process. The phone/network light will illuminate during the

call out process. If commissioning is successful, the alarm light will ash 5 short ashes and stop as verication. If

commissioning is unsuccessful, refer to the Service Pro Model 801P Installation and Operation Instructions.

3. If no telemetry system is installed, press and hold the RESET button on the control center for 5 seconds. The audible

alarm should sound and the alarm light should illuminate.

4. The system is operational once all installation and startup steps have been completed to this point. It will take 2 to 6

weeks for the system to reach biological maturity, depending upon system loading. DANGER: Make sure the system

access covers are in good condition and securely installed on the mounting castings. Never allow access

risers to be left uncovered or partially covered. Failure to secure access covers and safety nets could result

in bodily injury, illness or death. Riser safety nets are available from Norweco for concrete or plastic risers.

Routine Maintenance

The following should be performed every 12 months (or as required by your local governing regulations) by a qualied

service technician:

1. If applicable, inspect the euent discharge point to make sure there are no restrictions to the euent ow. If restrictions

are present, perform service as needed.

2. If euent sampling is required, it is recommended that a proper sampling port be installed downstream of the system.

3. Inspect the vent cap, perimeter vent and air pump for objects, plants, insects or debris that could impede the air intake.

Remove these items if present.

4. Check the air pump for proper operation. Check the air lter and clean or replace as required. Check the aeration

chamber for odor. A musty odor indicates the presence of aerobic conditions essential for proper treatment. A septic

odor indicates inadequate aeration, suggesting that the delivery of air into the aeration chamber has been restricted.

5. Check the aeration chamber and insure the diuser assembly is creating a rolling motion of the chamber contents. If

a rolling motion is not visible, verify air pump operation. Remove and clean diuser assembly if necessary.

6. Check the anoxic chamber and insure the mixing bar is operational. The recirculation pump operates on a

pre-programmed on/o cycle, so press the reset button if necessary to verify operation.

7. Inspect the ow equalization device. Rinse the design ow, sustained ow and peak ow ports with a garden hose and

insure they are free of debris. Clean the ow ports with a brush if necessary.

8. Use the hopper scraping tool to gently scrape all surfaces of the clarication chamber hopper.

9. The settled solids should be pumped from the Bio-Film Reactor tank to the pretreatment chamber. With the ow

equalization device securely in place, install the outlet blocking tool into the clarier outlet coupling prior to pumping.

Place the intake of the service pump at the bottom of the inuent chamber. Pump the contents from the bottom of

the Bio-Film Reactor tank until the accumulated solids are withdrawn and the water level is below the bottom of the

Bio-Film Reactor elements. Approximately 150 gallons will be removed during service. Rinse the media with a hose

during tank pumping. After pumping, remove the outlet blocking tool and allow the Bio-Film Reactor tank to rell to

normal operating level. Never leave the Bio-Film Reactor tank empty after pumping.

Page 9

10. Inspect the system to determine if complete pumping may be required. See "System Pumping" section of this document.

11. Upon completion of the inspection, insure that all access covers are properly reinstalled. Any missing or damaged

access covers should be immediately replaced. DANGER: Make sure the system access covers are in good

condition and securely installed on the mounting castings. Never allow access risers to be left uncovered

or partially covered. Failure to secure access covers and safety nets could result in bodily injury, illness or

death. Riser safety nets are available from Norweco for concrete or plastic risers.

12. Approved replacement parts are available from the authorized system dealer listed on the control center cover.

System Pumping

1. The Hydro-Kinetic system is a biological treatment device and will not require pumping as often as a septic tank.

Pumping of the system will likely be required at 3 to 5 year intervals depending upon system usage, loading and

treatment requirements. If pumping is required more frequently than every 2 years, there is an operational problem

with the system and it should be evaluated in greater detail.

2. If the service technician suspects that the system may require pumping, a settleable solids test should be performed on a

sample from the aeration chamber. The air pump must be removed from the aeration chamber riser to perform this test.

3. Immediately after removing air pump, dip a graduated cone or other clear container into the aeration chamber to a

depth of 2½ feet. Set the container on a level surface and then allow the solids to settle for 30 minutes while you

complete the service inspection. Do not disturb the container during the test.

4. After 30 minutes, read the level of solids and compare it with the total liquid volume in the container. Calculate the

percentage of settled solids volume (i.e. ½ full of solids equals 50%). If the settled material contains large pockets

of clear liquid, estimate the volume of these pockets and reduce the settled solids reading by that amount. A settled

solids reading of up to 80% indicates no adjustments are necessary. A settled solids level greater than 80% in the

aeration chamber indicates excessive solids and that the system should be pumped.

5. If it is determined that pumping is required, contact a tank pumping service licensed by the local regulatory agency.

The septage or biosolids from the system must be removed and disposed of in a manner consistent with federal, state

and local regulations. Advise the pumping service that they will be pumping approximately 1,500 gallons.

6. Turn o the air pump and recirculation pump before tank pumping.

7. Remove the access cover from the aeration and clarication chambers. Unplug the air pump and disassemble the

union located on the primary air connection. Remove the air pump, primary air connection and support base from

the aeration riser. Use the universal tool to bend exible diuser tubing and remove the diuser drop pipe assembly.

Connect the suction hose to the pump being used to evacuate the chamber.

8. Activate the pump and remove the aeration chamber contents. Pump the aeration chamber from the top down, to remove

biologically inactive material. Feed the hose down as the liquid is being evacuated from the aeration chamber. It is not

necessary to wash down the sidewalls or tank bottom. Pump only 75% of the volume out of the aeration chamber to

facilitate plant re-start. Replace the diuser drop pipe assembly. Reinstall the support base, primary air connection and

air pump. Reassemble the union in the primary air connection and plug in the air pump. Replace both access covers.

9. The Bio-Film Reactor tank should be pumped after the aeration chamber. Remove the Bio-Film Reactor tank

access cover. Lower the hose into the inuent chamber until it contacts the bottom of the tank. Withdraw the hose

approximately 2 inches. Completely pump 100% of the contents from the chamber and rinse the media with a hose

during tank pumping. Replace the Bio-Film Reactor tank access cover.

10. Next, pump the anoxic chamber. Remove the anoxic chamber access cover. Use the universal tool to bend exible

mixing bar tubing and remove the mixing bar drop pipe to allow access for the suction hose. Lower the hose until it

contacts the bottom of the tank. Withdraw the hose approximately 2 inches. Completely pump 100% of the contents

from the chamber. Reinstall the mixing bar drop pipe assembly and replace the access cover.

11. The nal chamber to pump is the pretreatment chamber. Remove the pretreatment chamber access cover. Break

up the scum mat to facilitate pumping. Lower the hose until it contacts the bottom of the tank. Withdraw the hose

approximately 2 inches. Activate the pump and remove 100% of the chamber contents. It is not necessary to wash

down the sidewalls or tank bottom. If solids are so concentrated that the suction hose cannot withdraw them, tank

contents may be backushed to break up the solid matter. Replace the pretreatment chamber access cover.

12. After pumping, rell all chambers to capacity with clean water. Return all plumbing and equipment to its properly

installed location. Replace any access covers that were removed. Turn on power to the air pump and the recirculation

Page 10

pump. Check for proper operation of all equipment. DANGER: Make sure the system access covers are in good

condition and securely installed on the mounting castings. Never allow access risers to be left uncovered

or partially covered. Failure to secure access covers and safety nets could result in bodily injury, illness or

death. Riser safety nets are available from Norweco for concrete or plastic risers.

Troubleshooting

This troubleshooting section provides solutions to the most common problems encountered in the operation of the system.

Control Center Alarming

1. Liquid in tank at level of high water alarm oat: system is ooded due to an obstruction in the ow

equalization device, outlet, euent line or disposal eld. Determine cause and remove obstruction, or make

repairs as required. Be sure to check euent disposal system for proper operation.

2. No rolling action in aeration chamber:

•Air pump is pumping air but there is an obstruction in the line between the air pump and diuser: disassemble

air line and remove obstruction.

• Diuser is plugged: remove and clean diuser.

• Air pump is not running: check power supply to air pump.

• Air is escaping through a leak in the plumbing assembly between air pump and diuser: identify and repair

air leak. If necessary, remove the diuser, diuser drop pipe assembly, and primary air assembly from the

aeration chamber and use a soapy water solution to thoroughly coat the plumbing and check for bubbles.

Repair any leaking air pipe or tting and retest.

3. Air pump is running but does not pump air: clean or replace air lter. Internal components are worn and

the air pump is failing. Rebuild or replace the air pump. Contact the authorized Norweco representative for

replacement components.

4. No mixing action in anoxic chamber:

• Recirculation pump is operating but there is an obstruction in the line between the recirculation pump and

mixing bar: disassemble mixing bar plumbing and remove obstruction.

• Recirculation pump is not operating. Pump needs replaced. Contact the authorized Norweco representative

for replacement components.

• Mixing bar is plugged: remove and clean mixing bar.

• Check valve is stuck in closed position: repair or replace check valve.

Septic Odor from System

1. No power to air pump: check air pump for proper operation. Insure the breaker is in the "on" position, the air

pump is plugged in and power is present (check with test light from Tool Kaddy)

2. Insucient air delivery to aeration chamber: see “Control Center Alarming”

3. Incomplete treatment due to hydraulic overloading: see “Hydraulic Overloading of System”

4. Water softener backwash discharging into system: notify owner to remove backwash line from system

5. Excessive solids in aeration chamber: evaluate chamber and pump if necessary

6. Excessive solids in anoxic chamber: evaluate chamber and pump if necessary

Hydraulic Overloading of System

1. Ground water entering tank through defective inlet or outlet seal: excavate and repair seal

2. Ground water entering system through crack in tank: excavate and repair crack with hydraulic cement

3. Ground water entering system through joint between riser and tank: excavate and reseal joint with

non-shrink grout or mastic

4. Roong down spouts, footer drains or oor drains tied into system: notify owner to relocate connection

downstream of system

5. Check valve is stuck in closed position: repair or replace check valve

©MMXXII NORWECO, INC. NORWALK, OHIO U.S.A / REV. 10/2022

PROGRESS THROUGH SERVICE SINCE 1906

www.norweco.com

Page 11

Sampling

Proper sampling techniques are important to ensure that the results are representative of system performance. To ensure

an accurate sample is collected, Norweco recommends that a sample port be installed immediately downstream of the

treatment system. The sample port should allow a free falling sample to be collected. Sample ports should be cleaned

before attempting to collect a sample.

If a sample port has not been provided, euent from the Bio-Film Reactor should be evaluated by collecting a sample from

the liquid above the Reactor Elements. The sample should be collected from 2-3" below the liquid surface to avoid collection

of any oating solids that could interfere with results.

If a sample port has not been provided, euent from the Phos-4-Fade lter should be evaluated by collecting a sample

from the liquid above the Phos-4-Fade media. The sample should be collected from 2-3" below the liquid surface to avoid

collection of any oating solids that could interfere with results.

Samples of the UV system euent must be collected from a sample port installed downstream of the UV disinfection system.

If an inuent sample is required, the inuent sample should be collected from the pretreatment chamber.

This manual suits for next models

1

Table of contents

Other norweco Water Filtration System manuals

norweco

norweco Singulair Green User manual

norweco

norweco Singulair 960 User manual

norweco

norweco Hydra-Max User manual

norweco

norweco Singulair Bio-Kinetic Configuration guide

norweco

norweco SINGULAIR BIO-KINETIC 960 User manual

norweco

norweco SINGULAIR GREEN BIO-KINETIC User manual

norweco

norweco BIO-DYNAMIC LF 4600 User manual

norweco

norweco BIO-DYNAMIC LF 1000 User manual

norweco

norweco HYDRO-KINETIC 3780L User manual