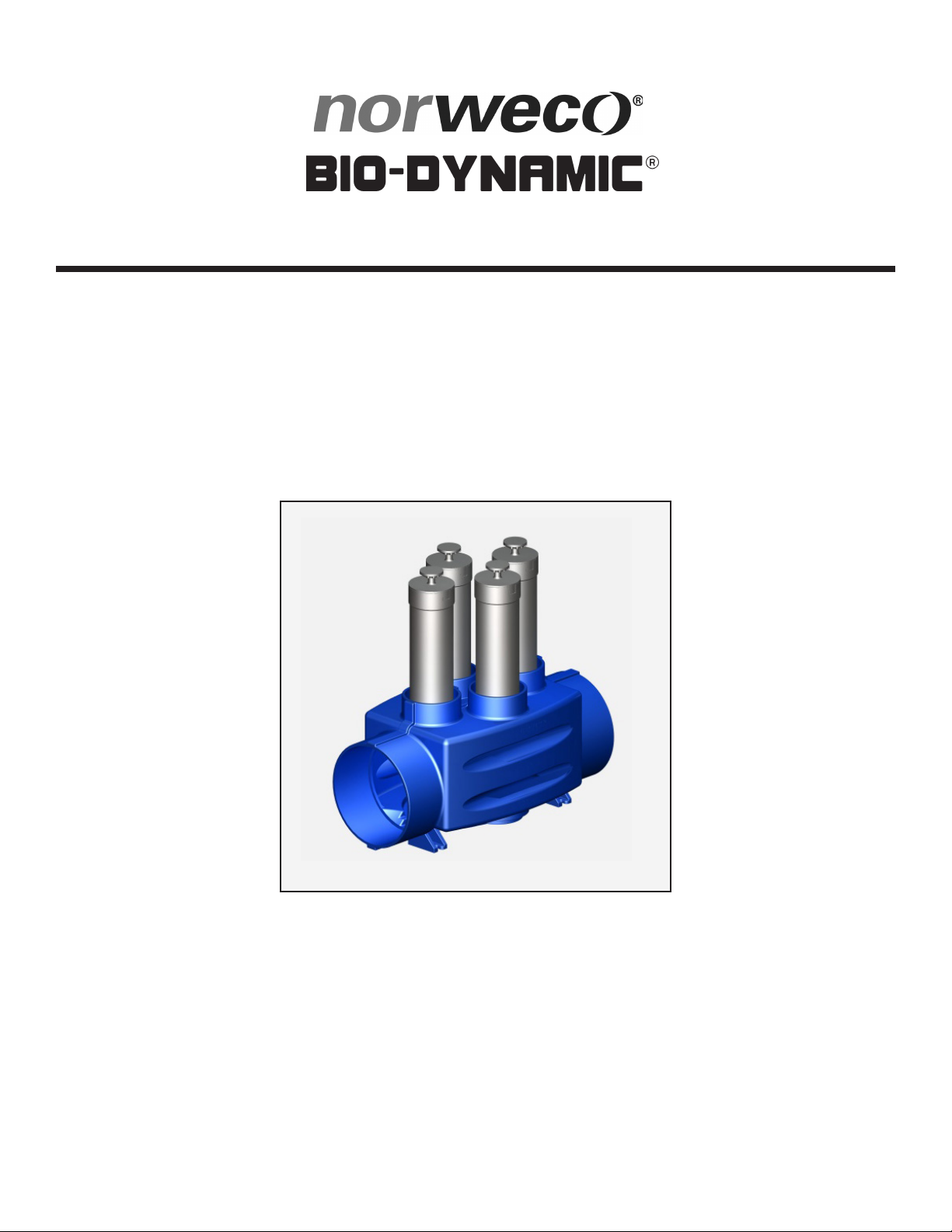

INSTALLATION AND OPERATION MANUAL

FOR MODELS LF 4600 AND LF 4800

INTRODUCTION

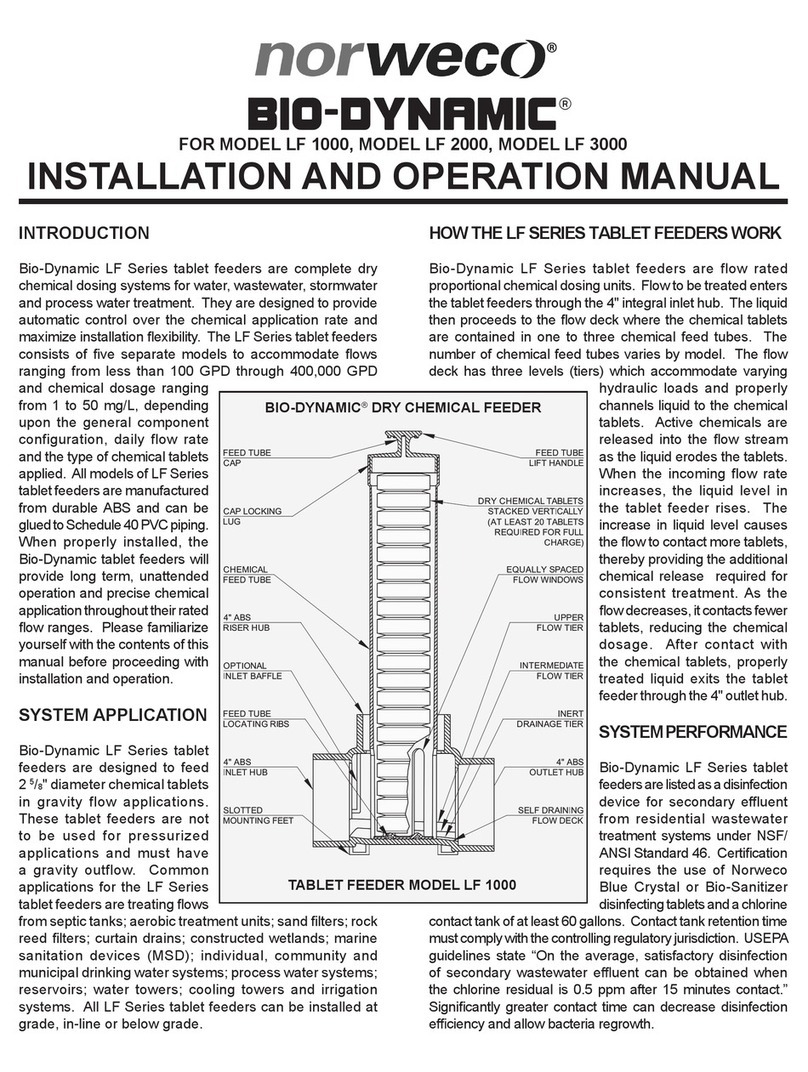

Bio-Dynamic LF Series tablet feeders are complete dry

chemical dosing systems for water, wastewater, stormwater

and process water treatment. They are designed to provide

automatic control over the chemical application rate and

eight inch inlet and outlet hubs

and can handle flows up to

Chemical dosage can range from

the general system component

type of chemical tablets applied.

manufactured from durable ABS

Bio-Dynamic tablet feeders will

provide long term, unattended

operation and precise chemical

application throughout their rated

yourself with the contents of this

manual before proceeding with

installation and operation.

SYSTEM APPLICATION

Bio-Dynamic LF Series tablet feeders are designed to feed

These tablet feeders are not to be used for pressurized

applications for the LF Series tablet feeders are treating

flows from septic tanks; aerobic treatment units; sand

municipal drinking water systems; process water systems;

reservoirs; water towers; cooling towers and irrigation

systems. All LF Series Bio-Dynamic tablet feeders can be

installed in-line at or below grade.

HOW THE LF SERIES TABLET FEEDERS WORK

proportional chemical dosing units designed to safely apply

deck where the chemical tablets are contained in one to

to the chemical tablets. Active

chemicals are released into the

the tablets. When the incoming

level in the tablet feeder rises to

more tablets, thereby providing

the additional chemical release

As the flow decreases, it

contacts fewer tablets, reducing

the chemical dosage. After

contact with the chemical tablets,

the tablet feeder through the

minimum of 15 minutes contact

time is recommended.

SYSTEM PERFORMANCE

Bio-Dynamic LF Series tablet feeders are listed as chlorine

Blue Crystal or Bio-Sanitizer disinfecting tablets and a

retention time must comply with the controlling regulatory

BIO-DYNAMIC®DRY CHEMICAL FEEDER

TABLET FEEDER MODEL LF 4600