Controller N2000

NOVUS AUTOMATION 5/9

KEY

The

key in front panel executes function 6 of Table 2:

Auto/Manual mode change. Operation of this key is enabled in

parameter

aven

avenaven

aven

. The MAN indicator lights when the manual control

mode is selected.

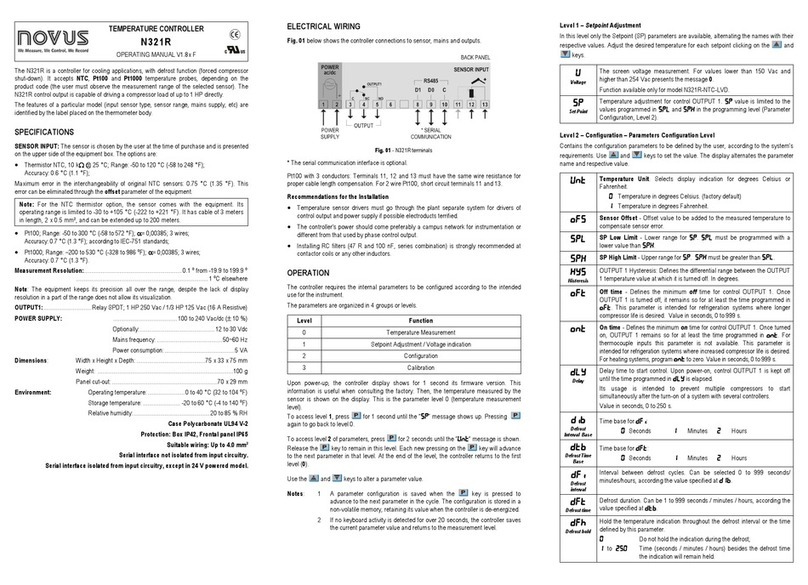

EXTRA 24 VDC PO ER SUPPLY – AUXILIAR P.S.

The controller provides a voltage power supply of 24 Vdc to excite

field transmitters with 25 mA current capacity. Available at the back

panel terminals 17 and 18.

CONFIGURATION PARAMETERS

OPERATION CYCLE

PV Indication

(Red)

SV Indication

(Green)

PV AND SV INDICATION: The status display shows the

present value of PV (Process Variable). The parameter

display shows SV (Set Variable).

The status display shows “- - - -“ whenever PV exceeds the

maximum range or there is no signal at the input. In case of

hardware error the status display will show Ern

ErnErn

Ern, where n is the

error code.

avto

avtoavto

avto

CONTROL MODE: YES indicates automatic control mode

(closed loop, PID or ON/OFF). NO indicates manual control

mode (open loop). Bumpless transfer from auto ↔ to manual

mode is available. If in doubt program YES.

PV Indication

(Red)

MV Indication

(Green)

MANIPULATED VARIABLE VALUE (MV): The upper display

shows PV value and the lower display shows the percentage

of MV applied to the control output. When in manual control

the MV value can be manually changed. When in auto mode

the MV value can only be viewed.

To distinguish the MV display from the SV display, the MV is

shown flashing intermittently.

Pr n

Pr nPr n

Pr n

RAMP AND SOAK PROGRAM SELECTION: Selects the

ramp and soak program to be executed (7 programs

possible). Refer to chapter 7 for R&S description.

rvn

rvnrvn

rvn

CONTROL ENABLE: YES means that the control output and

alarms are enabled and NO means they are disabled.

AUTO TUNING CYCLE

atvn

atvnatvn

atvn

AUTO-TUNE: YES enables the auto tuning of the PID

parameters and NO disables it.

Pb

PbPb

Pb

PROPORTIONAL BAND: Percentage of maximum input span.

0 to 500 %. Select zero for ON / OFF control.

xyst

xystxyst

xyst

CONTROL HYSTERESIS (in engIneering. units): This

parameter is only shown for ON / OFF control (Pb=0).

‘ ir‘

‘ ir‘‘ ir‘

‘ ir‘

INTEGRAL RATE: Integral time constant in repetitions per

minute (Reset).

dt

dtdt

dt

DERIVATIVE TIME: Derivative time constant, in seconds.

(t

(t(t

(t

CYCLE TIME: PWM period in seconds. Can only be viewed if

proportional band is other than zero.

act

actact

act

CONTROL ACTION: For Auto Mode only.

•

rE

rErE

rE Reverse Action usually used for heating.

•

dir

dirdir

dir Direct Action usually used for cooling.

bias

biasbias

bias

Offset for MV (manual reset). Range: -100 % to +100 %.

Default value: 0.

ovll

ovllovll

ovll

OUTPUT LOW LIMIT: minimum percentage value for MV

(Manipulated Variable) when in automatic control and PID.

Default value: 0.0 %

ovxl

ovxlovxl

ovxl

OUTPUT HIGH LIMIT: Maximum percentage value for MV

when in automatic control and PID. Default value: 100.0%

sfst

sfstsfst

sfst

SOFT START: Time in seconds during which the controller

limits the MV value progressively from 0 to 100 %. It is

enabled at power up or when the control output is activated.

If in doubt set zero.

Sp.a1

Sp.a1 Sp.a1

Sp.a1

Sp.a2

Sp.a2 Sp.a2

Sp.a2

Sp.a3

Sp.a3 Sp.a3

Sp.a3

Sp.a4

Sp.a4Sp.a4

Sp.a4

ALARM PRESET: Tripping point for alarm 1, 2, 3 and 4.

RAMP AND SOAK PROFILE PROGRAMMING CYCLE

tbas

tbastbas

tbas

TIME BASE: Selects the time base for the ramp and soak.

Valid for all profile programs.

0

0 0

0 - PT1 to PT7 values are in seconds;

1

11

1 - PT1 to PT7 values are in minutes;

Pr n

Pr nPr n

Pr n

PROGRAM TO BE VIEWED: Selects the ramp and soak

profile program to be edited/viewed in the following cycle

prompts (7 programs available).

ptol

ptolptol

ptol

RAMP AND SOAK TOLERANCE: maximum deviation

between PV and SV. Whenever this deviation is exceeded

the time counter is halted until deviation lowers to within the

tolerance. Set zero to disable this function.

Psp0

Psp0Psp0

Psp0

Psp7

Psp7Psp7

Psp7

RAMP AND SOAK SET POINTS (0 to 7): Set of 8 SV values

which define the ramp and soak profile segments. See also

PT1 to 7 and PE1 to 7 below.

Pt1

Pt1Pt1

Pt1

Pt7

Pt7Pt7

Pt7

RAMP AND SOAK SEGMENTS TIME (1 to 7): Set of 7 time

intervals in minutes or seconds (9999 max.) for the 7

segments of the ramp and soak program.

Pe1

Pe1Pe1

Pe1

Pe7

Pe7Pe7

Pe7

RAMP AND SOAK EVENT (1 to 7): Set of 7 values that

define which alarms must be activated during a ramp and

soak program segment. Alarm function depends on “rS

rSrS

rS”

setting (Table 3).

lp

lplp

lp

LINK TO PROGRAM: Number of the next profile program to

be linked to follow the current profile. Profiles can be linked to

make larger programs of up to 49 segments.

ALARM CYCLE

Fva1

Fva1Fva1

Fva1

ALARM 1 FUNCTION: Select options from Table 3.

Fva2

Fva2Fva2

Fva2

ALARM 2 FUNCTION: Select options from Table 3.

Fva3

Fva3Fva3

Fva3

ALARM 3 FUNCTION: Select options from Table 3.

Fva4

Fva4Fva4

Fva4

ALARM 4 FUNCTION: Select options from Table 3.

bla1

bla1 bla1

bla1

bla2

bla2 bla2

bla2

bla3

bla3 bla3

bla3

bla4

bla4bla4

bla4

ALARM BLOCK 1 TO 4: This function blocks the alarm at

power-up when the units is first energized.

YES enables and NO inhibits this blocking function. When

enabled the alarm will not be active at power-up waiting for

PV (Process Variable) to reach a non-alarm situation. From

this point on the alarm will be free to actuate should a new

alarm situation occur.

xya1

xya1xya1

xya1

ALARM 1 HYSTERESIS: Defines the differential range

between the PV value at which the alarm is turned on and

the value at which it is turned off (in engineering units).

xya2

xya2xya2

xya2

ALARM 2 HYSTERESIS: Same as above.

xya3

xya3xya3

xya3

ALARM 3 HYSTERESIS: Same as above.

xya4

xya4xya4

xya4

ALARM 4 HYSTERESIS: Same as above.

A1t1

A1t1A1t1

A1t1

ALARM 1 TIME 1: Defines the time (6500 sec. max.) during

which the alarm 1 output will be ON when alarm 1 is active.

Program zero to disable this function.

A1t2

A1t2A1t2

A1t2

ALARM 1 TIME 2: Defines the OFF state time for the alarm

1 output, after being ON during the time selected on ALARM

1 TIME 1. Program zero to disable this function.

A2t1

A2t1A2t1

A2t1

ALARM 2 TIME 1: Defines the time (6500 sec. max.) during

which the alarm 1 output will be ON when alarm 1 is active.

Program zero to disable this function

A2t2

A2t2A2t2

A2t2

ALARM 2 TIME 2: Defines the time during which the alarm 2

output will be, after being ON during the time selected on

ALARM 2 TIME 1. Program zero to disable this function.

Table 4 shows the advanced features that can be achieved

with these time functions.