N960 Controller

NOVUS AUTOMATION 6/6

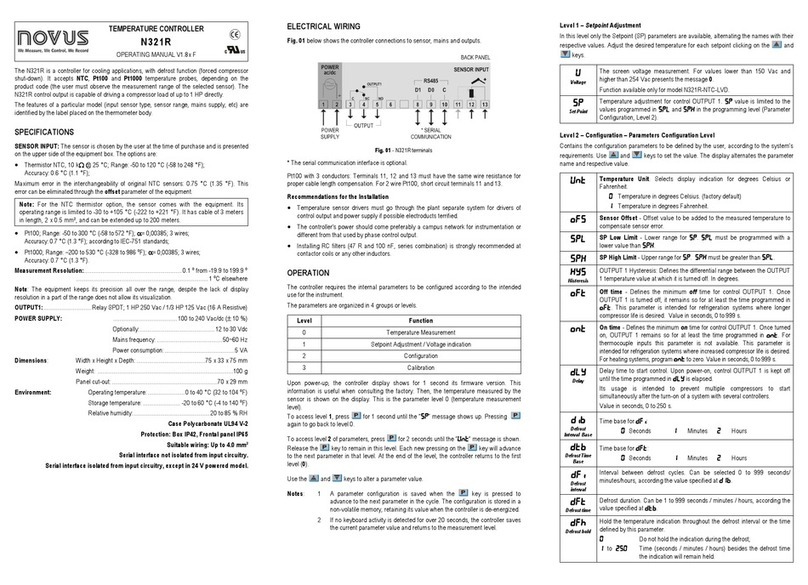

SPECIFICATIONS

DIMENSIONS:................................................96 x 96 x 90 mm (1/4 DIN)

............................................................... Approximate Weight: 330 g

CUTOUT IN THE PANEL:............................ 93 x 93 mm (+0.5 -0.0 mm)

POWER SUPPLY:........................ 100 to 240 Vac/dc (±10 %), 50/60 Hz

Optional 24 V:...................... 12 to 24 Vdc / 24 Vac (-10 % / +20 %)

Consumo máximo:................................................................... 6 VA

ENVIRONMENTAL CONDITIONS:

Operation Temperature: .................................................. 5 to 50 C

Relative Humidity:..............................................80 % max. up 30 ºC

For temperatures above 30 ºC, reduce 3 % for each ºC

Internal Use; Category of installation II, Degree of pollution 2;

altitude < 2000 m.

INPUT..............................Thermocouples, Pt100 (according to Table 1)

Internal Resolution: .......................................32767 levels (15 bits)

Resolution of Display:.........................................0.1 / 1 (°C / °F)

Rate of input reading:......................................up to 55 per second

Precision @ 25 °C:.......... J, K, T,E: 0.25 % of the span 1 ºC / °F

......................................... N, R, S, B: 0.25 % of the span 3 ºC / °F

................................................................... Pt100: 0.2 % of the span

Input Impedance: .................... Pt100 and thermocouples: >10 M

Measurement of Pt100: ..................Three wires type, (=0.00385)

with compensation for cable length, excitation current of 0.170 mA.

All input and output types are factory-calibrated. Thermocouples

according to standard NBR 12771 / 99, RTD’s NBR 13773 / 97;

OUTPUTS

OUTA / OUTB................................. Relay SPST-NA: 3 A / 240 Vac,

.......................................... General use, resistive load; 100 k cycles

OUTD.......................................... PULSE 12V / 0-20 mA or 4-20 mA

....................................................550 max. 31000 levels, Isolated

ELECTROMAGNETIC COMPATIBILITY:

............................................EN 61326-1:1997 and EN 61326-1/A1:1998

SAFETY: ..............................EN61010-1:1993 and EN61010-1/A2:1995

USB INTERFACE: 2.0, CDC class (virtual communications port),

MODBUS RTU protocol.

FRONT PANEL: IP65, polycarbonate UL94 V-2;

CASE: IP30, ABS+PC UL94 V-0;

STARTS UP OPERATION: after 3 seconds connected to the power

supply.

MODEL IDENTIFICATION

The sticker on the controller presents the identification of the model, as

described below.

N960 - A

Where A =........................... 24V for power supply 12 to 24 Vdc / 24 Vac

.............................................blank: power supply 100 to 240 Vac/dc

SAFETY INFORMATION

Any control system design should take into account that any part of the

system has the potential to fail. This product is not a protection or safety

device and its alarms are not intended to protect against product failures.

Independent safety devices should be always provided if personnel or

property are at risk.

Product performance and specifications may be affected by its

environment and installation. It’s user’s responsibility to assure proper

grounding, shielding, cable routing and electrical noise filtering, in

accordance with local regulations, EMC standards and good installation

practices.

SUPPORT AND MAINTENANCE

This product contains no serviceable parts inside. Contact our local

distributor in case you need authorized service. For troubleshooting, visit

our FAQ at m www.novusautomation.com.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

NOVUS warrants to the original purchaser that this product is free from

defects in material and workmanship under normal use and service within

one (1) year from the date of shipment from factory or from its official

sales channel to the original purchaser.

NOVUS liability under this warranty shall not in any case exceed the cost

of correcting defects in the product or of supplying replacement product

as herein provided and upon the expiration of the warranty period all such

liability shall terminate.

For complete information on warranty and liability limitations, check

appropriate section in our web site: www.novusautomation.com/warranty.