N480

3

1. INSTALLATION

1.1 PANEL ASSEMBLY

The controller should be installed in a panel cut out as specified in item 2.1. First remove the mounting clamp and insert the

controller into the panel cut out. Place the unit into the panel cut-out and slide the mounting clamp from the rear to a firm

grip at the panel.

The internal circuitry can be fully removed from the housing without disconnecting any wiring. By using the thumb just

press the tab in the lower part of the front panel, grab firmly the front panel and pull out the circuitry from the housing.

1.2 ELECTRICAL CONNECTIONS

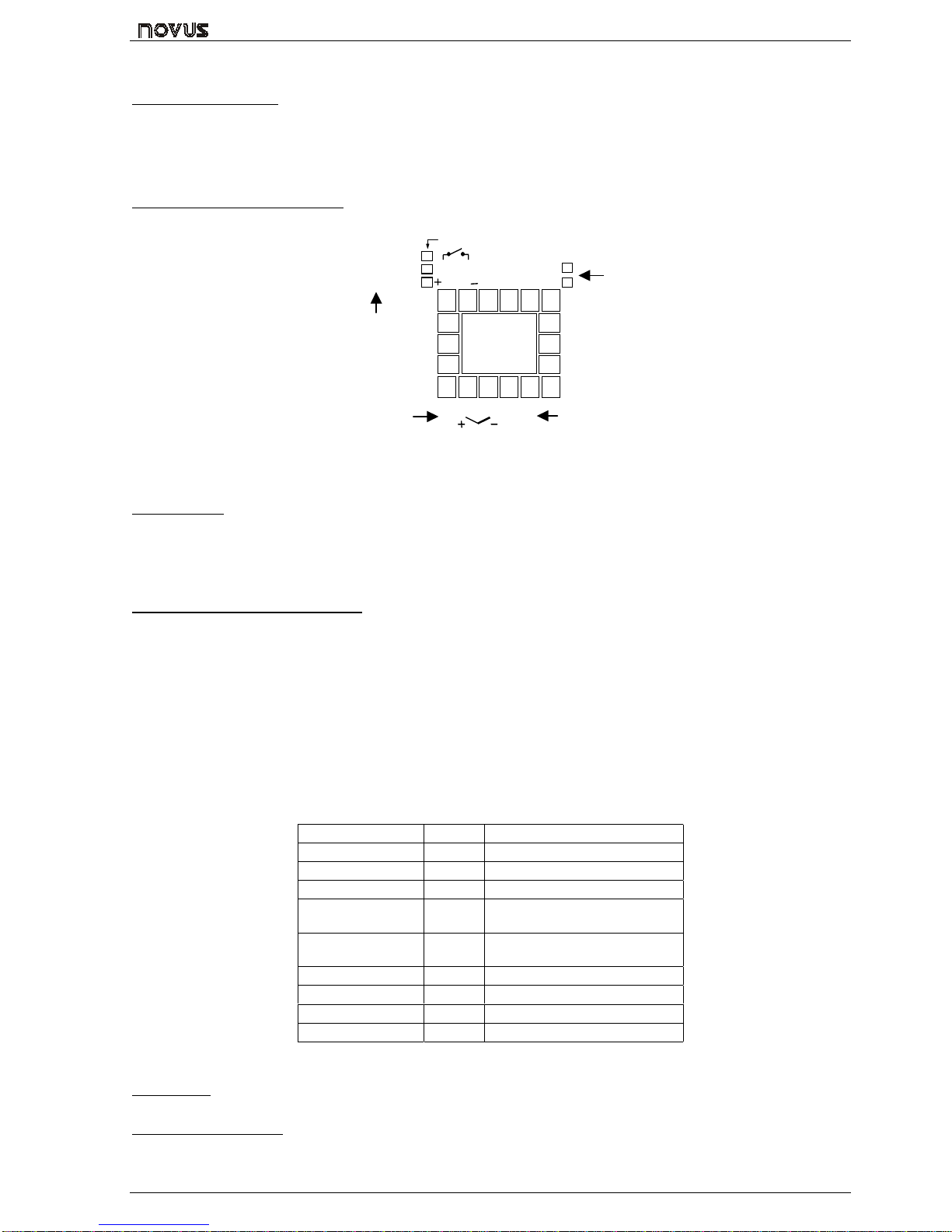

Figure 1 shows the electrical terminals of the controller.

123456

78910 11 12

13

14

15 18

17

16

POWER

AC/DC

15-30V

85-264V

SENSOR INPUT AL2

OUT-B

OUT-A

PULSE

4-20mA

RELAY OUTPUT

PULSE OUTPUT

4-20mA OUTPUT POWER

ALARM 2

CONTROL

OUTPUT

OR ALARME 1

Figure 1 - Electrical connections

2. SPECIFICATIONS

2.1 GENERAL

•Dimensions: 48x48x106mm (1/16 DIN). Panel cut-out: 45,5x45,5mm

•Weight: 140g (1 relay), 160g (3 relays)

•Power: 85 to 264Vdc/ac, 50/60Hz, 3VA max. Optional: 15 to 30Vdc/ac

•Operation: 0 to 55°C, humidity 20 to 85%

2.2 TEMPERATURE SENSOR INPUT

•Pt100: 3-wire connection. Excitation current: 170µA

•Thermocouple input impedance: 10MΩ

•A/D converter resolution: 15000 steps

•Sampling rate: 10 measurements per second

•Auto zero and auto range

•Accuracy: 0.2% of full scale for Pt100 and 0.25% of full scale ±1°C for T/C

Thermocouples are connected to terminals 8 and 9 with positive in terminal 8.

Pt100 sensors are connected to terminals 7, 8 and 9, as indicated in figure 1. For full compensation of cable resistance

only cables with equal wire electrical resistance should be used.

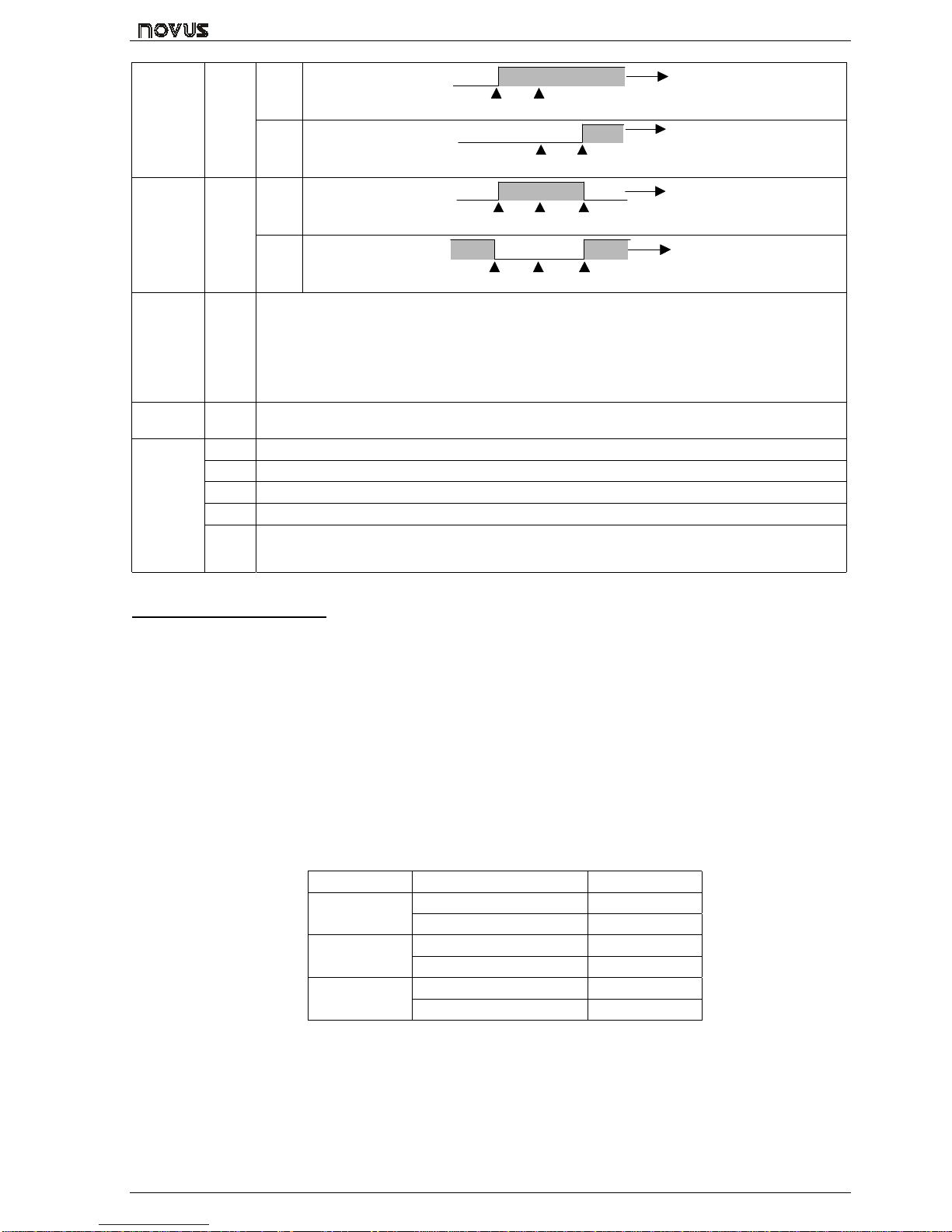

Table 1 shows the sensor types accepted and their respective codes. via keyboard.

TIPO CÓDIGO FAIXA

J0-50 a 760°C (-58 a 1400°F)

K1-90 a 1370°C (-130 a 2498°F)

S20 a 1760°C (32 a 3200°F)

Pt100 (Resolução

0,1°C) 3-199.9 a 530.0°C (-199.9 a

986.0°F)

Pt100 (Resolução

1°C) 4-200 a 530°C (-328 a 986°F)

T5-100 a 400 °C (-148 a 752°F)

E6-30 a 720°C (-22 a 1328°F)

N7-90 a 1300°C (-130 a 2372°F)

R80 a 1760°C (32 a 3200°F)

Table 1 - Sensor types, codes and ranges

2.3 POWER

Mains power is connected to terminals 5 and 6. Check the upper side of the housing for proper power indication.

2.4 CONTROL OUTPUT

•Relay output: SPST (U type) relay. Maximum current 3A/250Vac.

•Voltage pulse output: 5Vdc/20mA