www.nationalrailwaysupply.com

1-800-357-3572 4 38542D

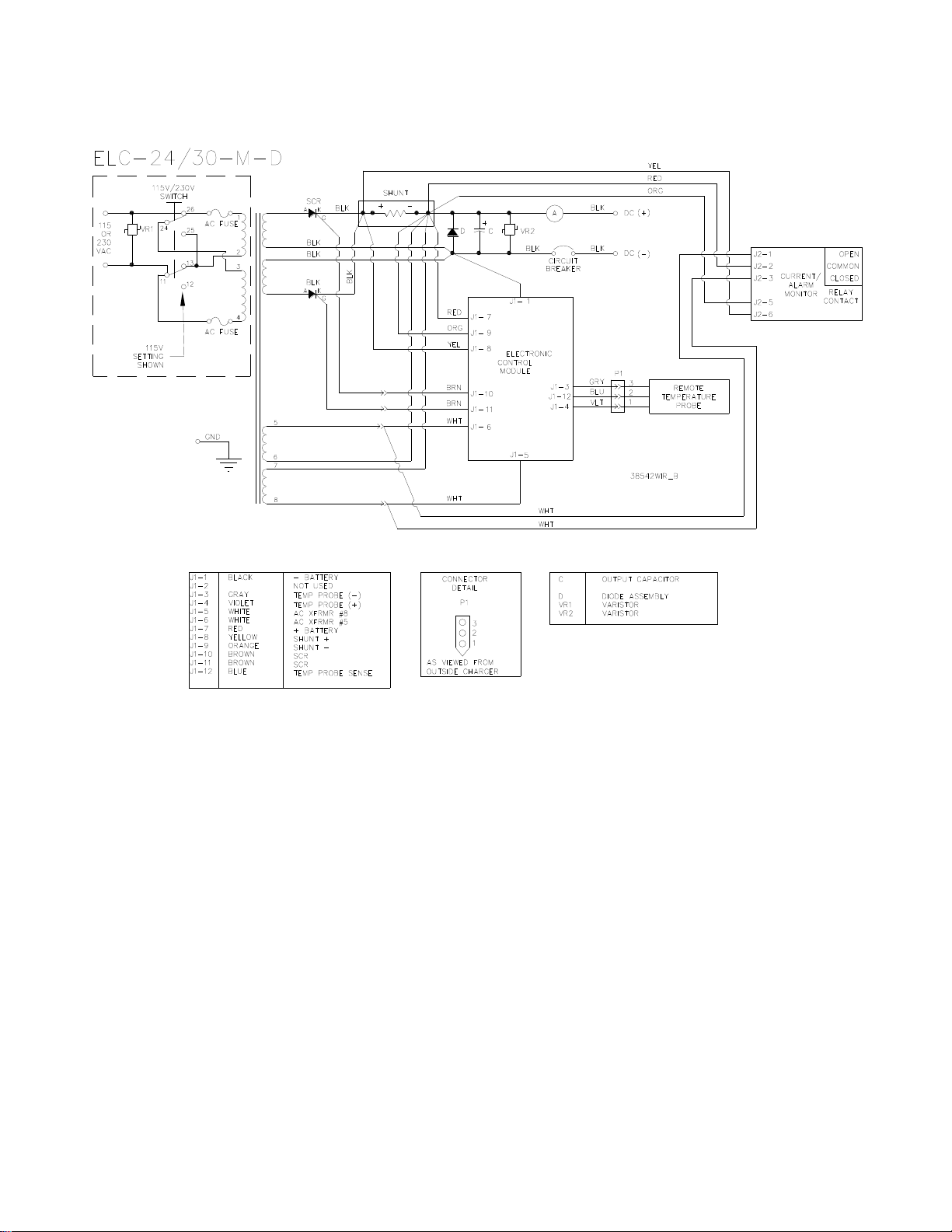

5. AC ELECTRICAL SUPPLY

The charger must be connected to a single-phase,

50/60 Hertz AC power source, which can be either

115 or 230 VAC depending on the charger input

voltage selection switch setting. Use an appropriate

size wire for the conditions and for the AC amperage

shown on the ratings information on the charger.

Quarter-inch (1/4") ring terminals are required for

proper connection to the AC input and ground

binding posts (A.A.R.) located on the front of the

charger. Open the small door cover on the front of

the charger by pulling out on the push tabs. Connect

the AC power terminals on the two posts on the right,

as marked on the panel behind the posts. Connect

the AC ground to the terminal lug provided.

WARNING: FAILURE TO PROPERLY

CONNECT THE AC VOLTAGE CONDUCTORS

COULD CAUSE SERIOUS DAMAGE TO THE

CHARGER. BE SURE TO SET THE VOLTAGE

SELECTION SWITCHES ON THE FRONT OF THE

CHARGER TO THEIR PROPER POSITION.

WARNING: DO NOT OPERATE THE

CHARGER WITHOUT PROPER GROUNDING.

IMPROPER GROUNDING CAN RESULT IN THE

RISK OF AN ELECTRIC SHOCK.

6. DC OUTPUT

The DC output wires, are connected on the two left-

most binding posts as labeled on the panel behind

the binding posts (positive on the left and negative

on the right). The DC cables should have quarter-

inch (¼") ring terminals for connecting them to the

binding posts. Check to make sure the polarity of

the DC output wires is the same as those connected

to the battery. The charger will not operate in a

reversed polarity condition. WHEN CONNECTING

THE DC WIRES TO THE CHARGER WITH THE AC

POWER DISCONNECTED, A SPARK MAY

OCCUR. This is caused by the output capacitors

being charged by the batteries. If the DC polarity is

reversed, a circuit breaker will protect the charger

from internal damage. Correct the reversed wires

and push the circuit breaker button back in. Replace

the door cover on the front of the charger after

tightening all of the binding post nuts.

WARNING: DO NOT TOUCH THE

CHARGER'S TERMINALS OR AN ELECTRICAL

SHOCK COULD OCCUR. A VOLTAGE IS

PRESENT ON THE DC TERMINALS EVEN AFTER

THE AC IS DISCONNECTED BECAUSE OF THE

ENERGY STORED IN THE CAPACITOR.

7. TEMPERATURE PROBE

The external temperature probe is an optional way of

extending battery life by using temperature

compensation. One end of the temperature probe

cable has a three-pin plug, which plugs into a

receptacle labeled TEMP PROBE on the front of the

charger. The other end of the cable has the

temperature sensor sealed either in a terminal or

small metal box.

WARNING: IT IS IMPORTANT TO MOUNT

THE TEMPERATURE PROBE ON THE

BATTERIES FOR PROPER TEMPERATURE

COMPENSATION. IF THIS CANNOT BE DONE,

LOCATE THE PROBE AS LOW AS POSSIBLE IN

THE BUNGALOW OR CABINET.

Terminal-Type Probe

The terminal-type probe should be attached to the

negative (-) battery post near the center of the

battery pack. If the threaded stud is long enough

above the battery jumper nut, attach the probe with

another nut. Torque this nut to proper specifi-

cations. If the stud is too short, the nut holding the

jumper wire will need to be removed. Open or

remove the load and charging circuits to the

batteries. Remove the nut holding the jumper and

add the probe, then torque the nut to the proper

specifications. Then close or connect the load and

charging circuits back to the batteries.

Securely fasten the temperature probe cable to

protect the probe from being torn from the

battery. Secure the probe's cable to a fixed object

to ensure the probe will not be pulled loose. Use a

cable tie mount on the battery or on the adjacent

battery, if necessary.

8. OPERATION

The battery charger is adjustable with the three

rotary switches on the front of the charger. The

switches (settable between 20.0 and 35.0) determine

the float voltage for the batteries. SET THE FLOAT

VOLTAGE TO THE BATTERY MANUFACTURER'S

SPECIFIED VOLTAGE FOR 77F. The charger will

then electronically charge the batteries to the voltage

specified on the switches. To set the switches, use

a small screw-driver and turn the switch so that the

arrow head on the slot is pointing to the desired

number. Set the switches in the following manner. If

the desired battery voltage is 26.8 volts, set the top

switch to 2, the middle switch to 6, and the bottom

switch to 8 (see the figure below). This will provide

you with the proper charging voltage. BE SURE

EACH SWITCH IS SET ON A NUMBER AND NOT

BETWEEN NUMBERS. If a switch is set between

numbers, the output current will go to zero and the

yellow charging LED will flash.