8

Machine Inspection

•After unpacking, Inspect the machine for damage or

missing components. If damage is found, contact the

freight company to le a freight claim.

Before First Use

Battery Installation to be performed by qualied

technician according to the battery connections dia-

gram on the machine (See Marking #2).

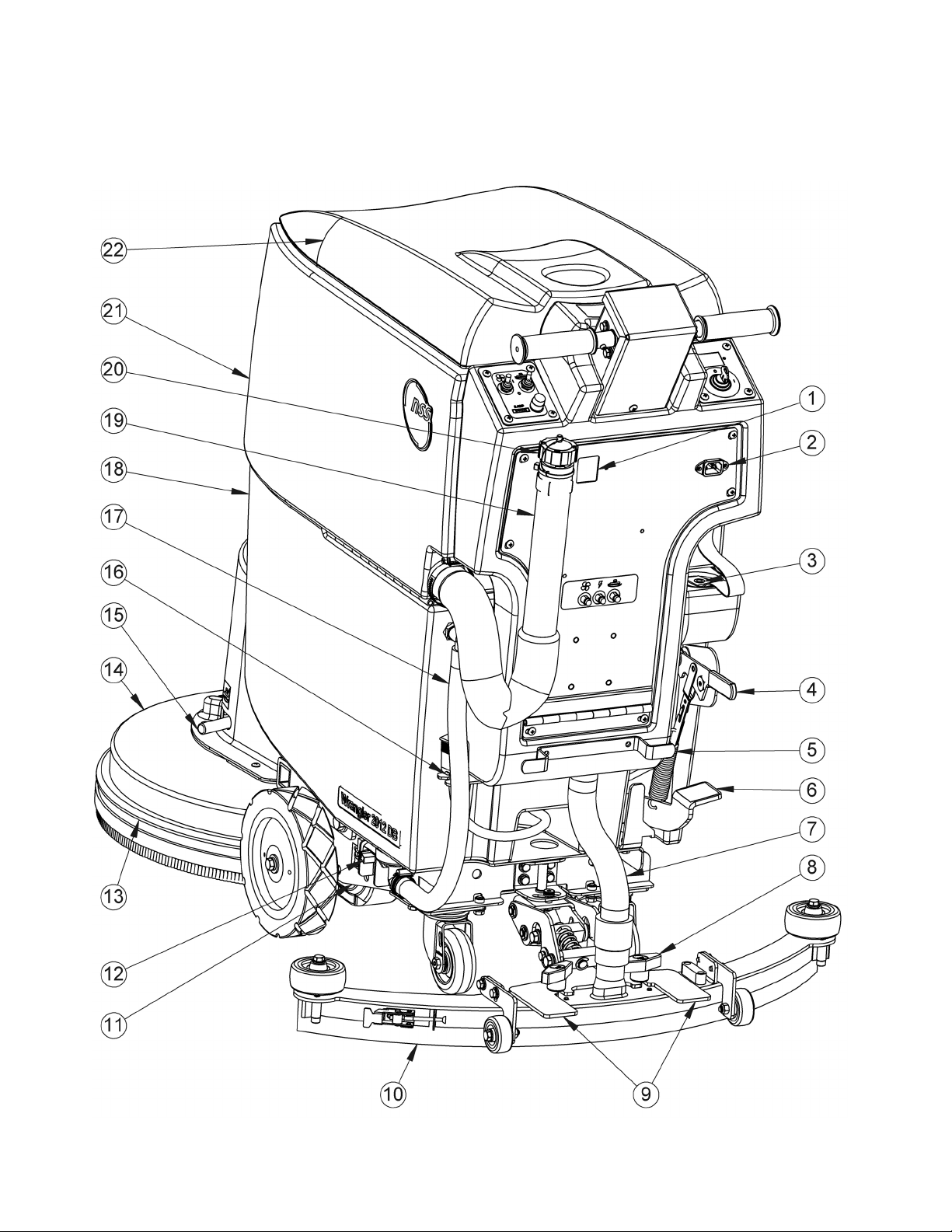

• Lift open the Recovery Tank (#21 Figure 1) using

the strap (#32 Figure 4).

• Plug the battery pack connector (#30 Figure 4)

into the mating connector on the machine.

• Install the squeegee, and connect the hose to the

squeegee. See SQUEEGEE INSTALLATION secton.

• Install pads/brushes. See PAD/BRUSH INSTALLA-

TION section.

• Charge the batteries fully. SEE BATTERY CHARGER

SECTION.

• Note: The machine is disabled when the battery

charger is connected to the wall outlet.

MACHINE COMPONENTS

Operator Control Panel

The operator control panel is located at the upper rear

area of the back of the machine. This panel has com-

ponents that control various machine functions.

Wrangler 2012 AB (See Figure 6):

• The key switch (#42) located in the back of the

control box turns the machine on and o. Power

on is indicated when the Battery Meter (#41) is

illuminated.

• The Operator Handles (#39) allow the operator to

control the direction of the machine.

• The Battery Meter (#41) shows the state of charge

of batteries. Fully charged batteries indicated when

the right LED bar is lit. The LED bar will move to

the left as the batteries are discharged. 70% dis-

charge indicated by the second left LED bar ash-

ing. 80% discharge indicated by alternate both left

LED bars ashing.The battery meter is equipped

with a relay that will open, turning o the ma-

chine, when the battery voltage has dropped to its

lowest permissible level.

• The Hour Meter (#41) indicates the hours the

Brush Motor has been used. The hour meter is non

resettable.

• The switch lever (#40) in front of the right control

handle grip (#39) turns on the Brush/Pad Motor

and dispences the solution when the brush/pad

motor switch (#24) is on.

• The Circuit Breaker (#36) controls the Brush/Pad

Motor. Push in to reset.

• The Circuit Breaker (#38) controls the Vacuum

Motor. Push in to rest.

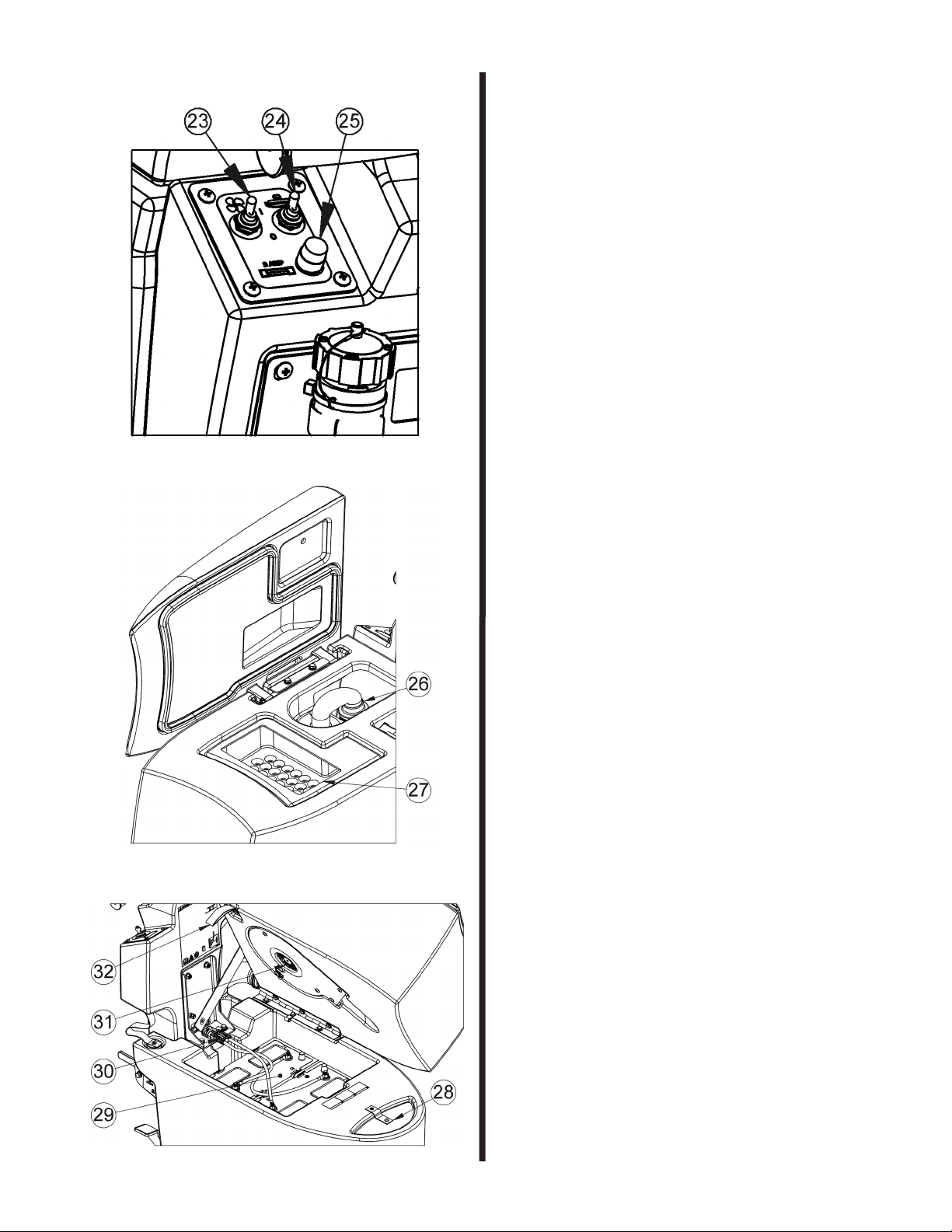

Left Control Panel (See Figure 2.)

• The Vacuum switch (#23) controls the Vacuum

Motor.

• The Brush/Pad Motor switch (#24) controls the

Brush/Pad Motor.

• The Battery Charger Fuse (#25) must be in work-

ing order for the machine to work.

Wrangler 2012 DB (See Figure 5):

• The key switch (#35) located in the right control

panel turns the machine on and o. Power on is

indicated when the Battery Meter (#34) above the

key switch is illuminated.

• The battery meter (#34) shows the state of charge

of batteries during operation. When the batteries

are fully charged, all of the LED’s are illuminated.

As the batteries discharge, the LED’s start to turn

o, one at a time, from right to left. The battery

meter is equipped with a relay that will open, turn-

ing o the machine, when the battery voltage has

dropped to its lowest permissible level. If the ma-

chine is operated until it is automatically shut o,

turn o the key switch, the brush switch, and the

vacuum switch. Then turn on the key switch, and

the machine can be driven to a charging location.

• In the middle of the operator panel are two (2)

rubber twist grips (#33). These grips rotate for-

ward moving and backward to control the direction

and speed of the machine. The farther the grips

are rotated, the faster the machine will move.

These twist grips have a feature that returns the

machine to the neutral position when the handles

are released.

• The Brush/Pad Motor turns on when the brush/pad

switch (#24 Figure 2) is on and the twist grips are

rotated in either direction.

• The solution is dispenced when the brush/pad

switch (#24 Figure 2) is on and the twist grips are

rotated in either direction but does not control the

amount of solution dispenced.

• The Circuit Breaker (#36) controls the Brush/Pad

Motor. Push in to reset.

• The Circuit Breaker (#37) controls the Drive Motor

Controller and the machine. Push in to reset.

• The Circuit Breaker (#38) controls the Vacuum

Motor. Push in to rest.

Left Control Panel (See Figure 2.)

• The Vacuum switch (#23) controls the Vacuum

Motor.

• The Brush/Pad Motor switch (#24) controls the

Brush/Pad Motor.

• The Battery Charger Fuse (#25) must be in work-

ing order for the machine to work.

Common Machine Components

(See Figures 1,3 and 4)

Solution Tank

• The solution tank (#18) is the lower part of the

machine body and has a capacity of 12 gal (45 L).

• The solution tank can be lled through the front

ll opening (#28). Lift the cover to access the

opening. Replace cover to prevent splashing when

machine is moving.

• The solution tank can be lled through the rear ll

opening (#3). Lift the plug to access the opening.

Replace the plug to prevent splashing when the

machine is moving.

• The amount of water in the solution tank is seen

in the site gage and drain hose (#17) at the right

rear of the tank. The solution tank can also be

emptied through this hose.

Recovery Tank

• The recovery tank (#21) is the upper part of the

machine body and has a capacity of 14 gal (53 L).

• The recovery tank collects the dirty solution.