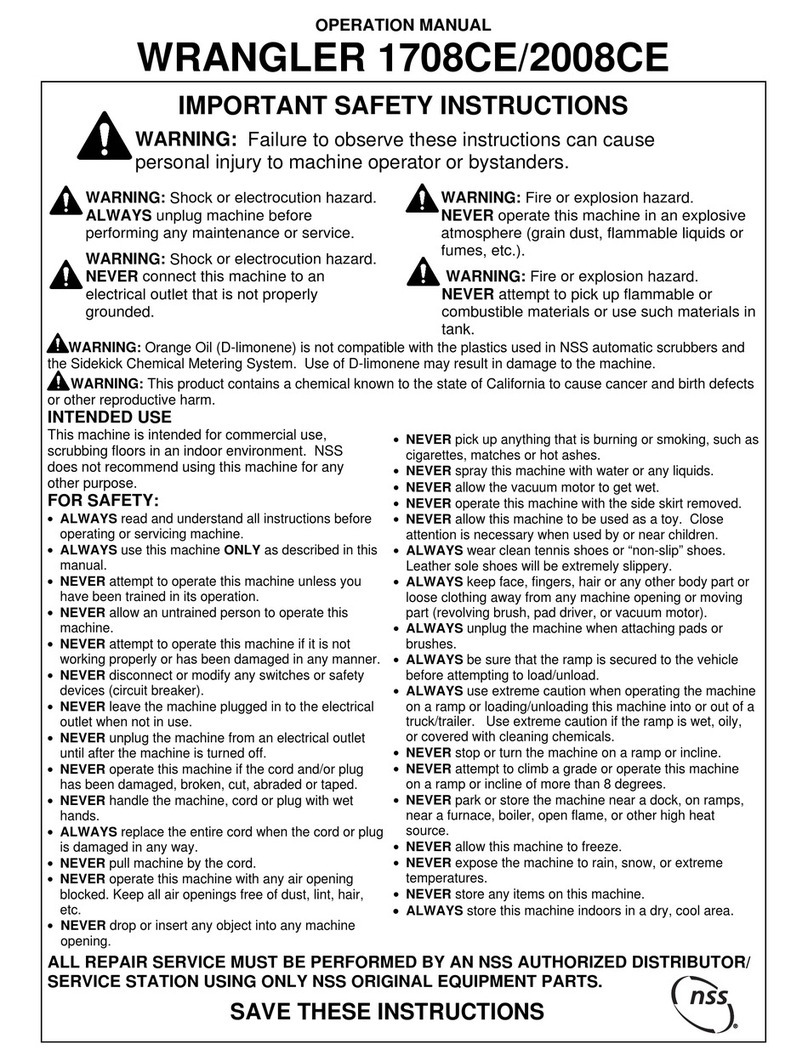

WARNING: Fire or explosion hazard. Never attempt to pick

up flammable or combustible materials or use such

materials in tanks.

Orange Oil (D-limonene) is not compatible with the plastics

used in NSS automatic scrubbers and the Sidekick

Chemical Metering System. Use of D-limonene may result

in damage to the machine.

WARNING Do not use flammable liqids.

Only use cleaning detergents free from solvents,

hydrochloric acid and hydroflouric acid.

Do not use high foaming detergents.

STORAGE:

CAUTION This machine shall be stored indoors only.

NEVER park or store the machine near a dock, on ramps,

near a furnace, boiler, open flame, or other high heat

source.

NEVER allow this machine to freeze.

NEVER expose the machine to rain, snow, or extreme

temperatures.

NEVER store any items on the machine.

Operating temperature range: 40°- 104°F (5° - 40°C)

Personal Protective Equipment:

o Follow safety instructions provided with the cleaning

detergents.

o Follow detergent manufacturer’s instructions regarding

Personal Protective Equippment.

BATTERIES SAFETY INFORMATION

WARNING Failure to observe these warnings can cause

personal injury to machine, operator, or bystanders.

WARNING Batteries emit hydrogen, which can cause fire or

explosion.

NEVER smoke, light a match, or cause a spark during

operation or charging.

ALWAYS charge in a well-ventilated area away from open

flame.

ALWAYS read and understand all instructions before

installing or charging batteries.

NEVER attempt to install or charge batteries unless you

have been trained to do so.

NEVER allow an untrained person to install or charge

batteries.

ALWAYS wear eye protection and protective clothing to

avoid contact with battery acid.

ALWAYS remove all jewelry when working on or near the

batteries.

ALWAYS turn off all switches during installation and

service.

ALWAYS disconnect the battery leads before performing

any service or repair.

NEVER Lay anything on top of batteries as arcing may

occur.

IF CONTACT WITH BATTERY ACID OCCURS, follow

these instructions:

SKIN – rinse area with water.

EYES – Flush with water for 15 minutes.

INTERNAL – Drink water or milk. Follow with Milk of

Magnesia, beaten egg or vegetable oil. Call a physician

immediately.

BATTERY INSTALLATION

ALWAYS use two people to install, as batteries are heavy.

ALWAYS turn off all machine switches.

ALWAYS position batteries as shown on the machine

installation decal to maintain machine balance.

ALWAYS connect batteries as shown on the machine

installation decal to avoid shorting out the batteries and the

electrical system.

BATTERY CHARGING SAFETY

ALWAYS read instructions carefully.

ALWAYS use the NSS supplied charger with proper voltage

rating.

ALWAYS plug the charger into an earthed socket outlet.

NEVER charge a frozen battery.

NEVER touch uninsulated portion of output connector or

uninsulated battery terminal.

ALWAYS disconnect the AC supply before making or

breaking the connections to the battery while charging.

NEVER operate charger if the AC supply cord is damaged

or if the charger has received a sharp blow, been dropped,

or otherwise damaged in any way.

For Flooded lead acid batteries only, (does not apply

sealed maintenance free batteries).

ALWAYS check to ensure the battery water level covers

the battery plates before charging.

ALWAYS check water level after charging and add distilled

water if necessary to bring level to the bottom of the fill

hole.

NEVER

overfill batteries as battery

and machine damage may result.

ALWAYS wipe any acid from the top

of batteries using a soap solution.

ALWAYS study battery manufacturers’ specific precautions

such as recommended rates of charge.

ALWAYS reattach caps to batteries. Do not charge with

caps loose or removed.

ADD only distilled water.

GROUNDING OF ELECTRICAL EQUIPMENT

BATTERY CHARGER

WARNING: Improper connection of the equipment–

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if you are in

doubt as to whether the outlet is properly grounded. Do not

modify the plug provided with the charger. If outlet is not

suitable for safe use; have a properly grounded outlet installed

by a qualified electrician.

Always use a properly grounded 3-wire extension cord, which

has male and female plugs. If 25 foot [7.6m] extension cords

are used, the electrical carrying capacity should be no less

than 14-3 ST., 50 foot [15.2m] extension cords no less than

12-3 ST

GROUNDING INSTRUCTIONS

This charger shall be grounded while in use to protect the

operator from electric shock. The charger is provided with a

three-conductor cord and a three-contact grounding type

attachment plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in

accordance with all local codes and ordinances. The green

conductor in the cord is the ground wire. Never connect this

wire to other than the grounding pin of the attachment plug.

Check nameplate on the charger to be sure voltage and cycle

stated is the same as the electrical outlet. Do not attempt to

plug a 120-volt charger into a 240-volt outlet or a 240-volt

charger into a 120-volt outlet. If the cord provided with the

charger has an attachment plug as shown in Figure A. below, it

is intended for use on a nominal 120-volt circuit. If a properly

grounded receptacle as shown in Figure A is not available, an

adapter may be installed as shown in Figure B if the outlet box

that houses the receptacle is grounded. Be sure to fasten the