S

Sa

af

fe

et

ty

y

I

In

ns

st

tr

ru

uc

ct

ti

io

on

ns

s

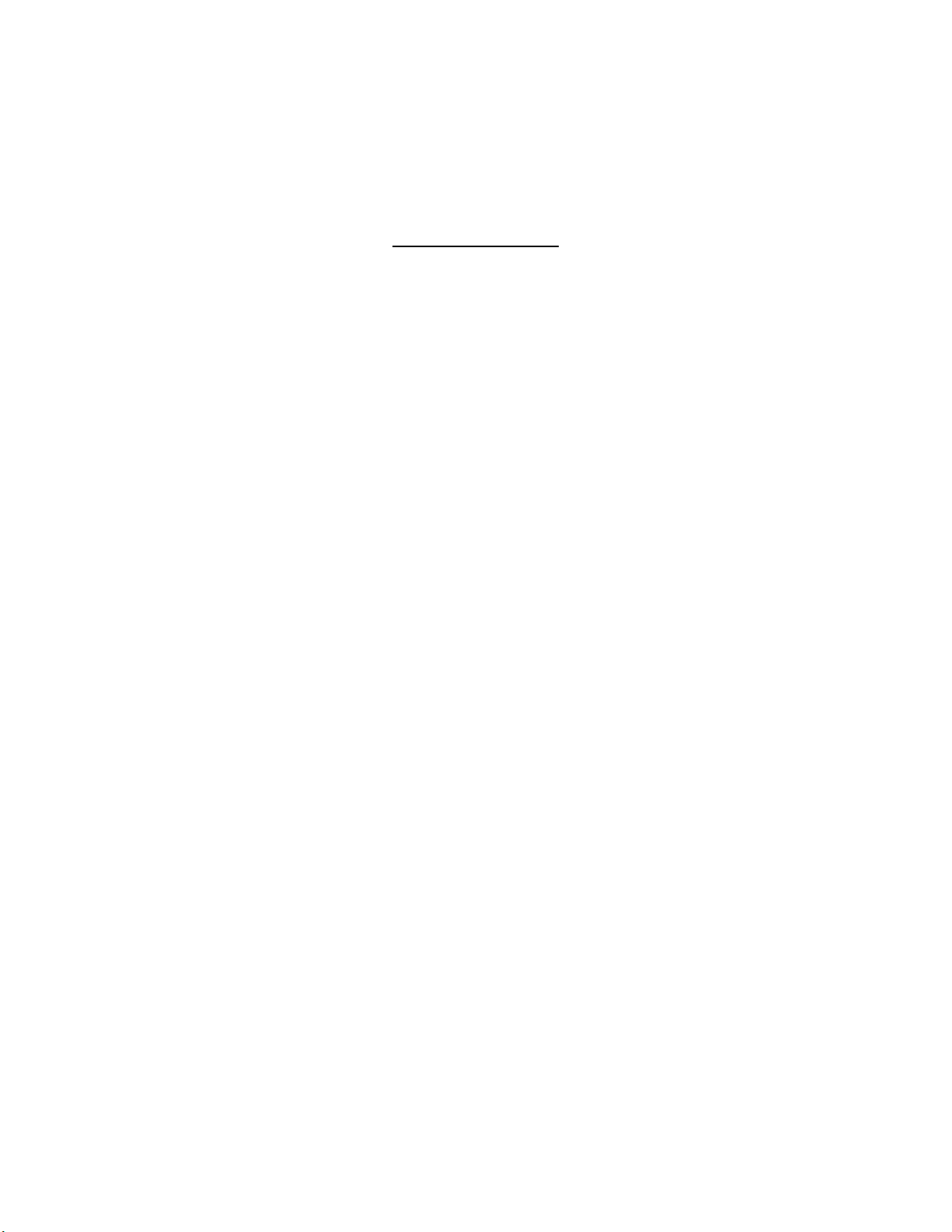

CAUTION: This machine should never be operated

by anyone who is not familiar with the product and

has not read the instruction manual. Do not allow

children to operate the Mower Carrier.

All persons operating this machine

should read and understand the

Instruction Manual.

Read and understand all safety decals

located on the machine.

Keep Safety Decals clean and legible at

all times.

Replace Safety Decals that are missing

or become illegible.

Do not allow anyone to ride on the

machine.

Be sure machine is attached securely to

the tractor before operating or

transporting.

Inspect the Mower Carrier daily.

Lubricate and repair or replace parts as

needed.

Maintain and keep all Safety Shields in

place.

Before operating the machine inspect for

loose or damaged bolts or parts and

make necessary repairs before starting.

All bystanders should be a safe distance

from the machine when in operation.

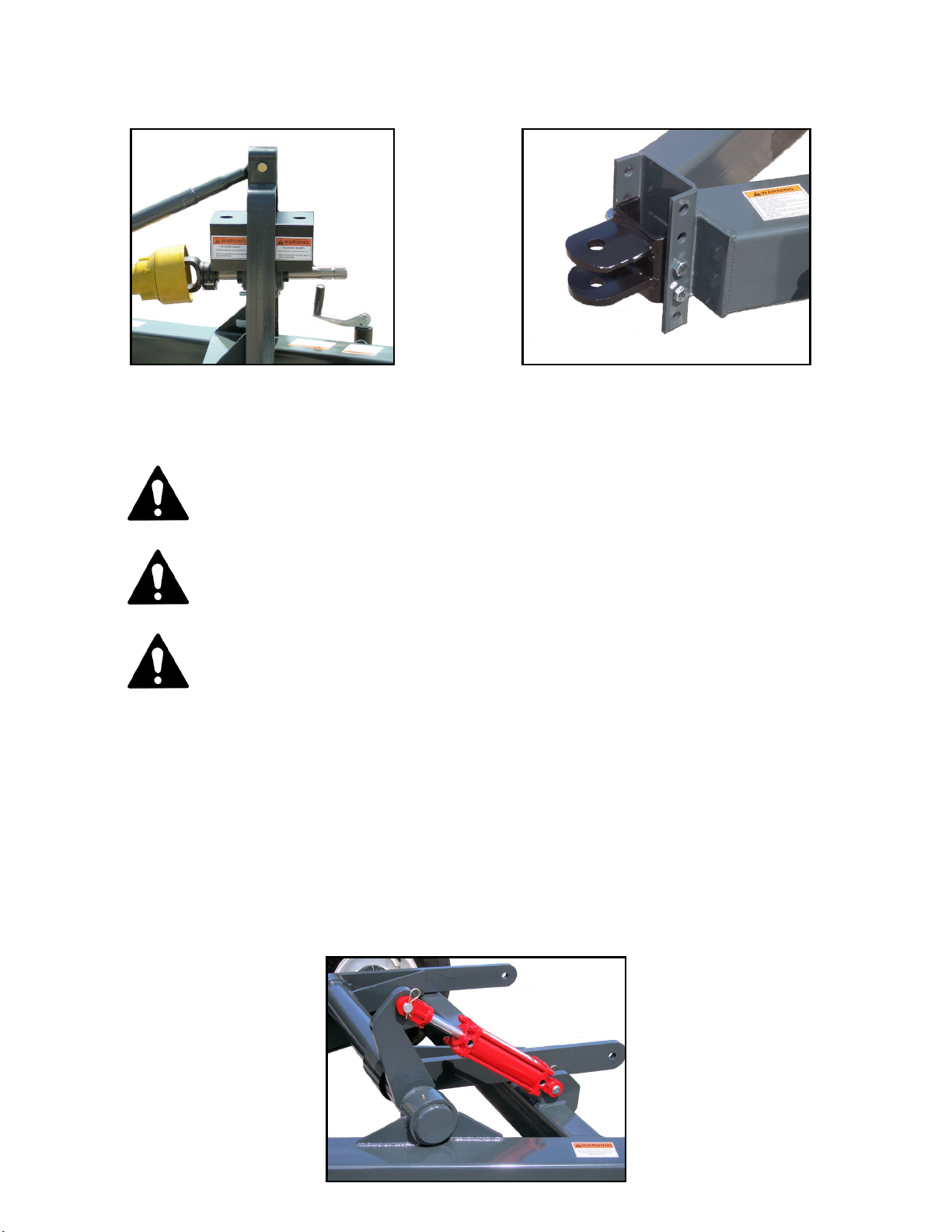

High-pressure oil leaks can penetrate

skin causing serious injury. Do not use

your finger or other skin to check for

leaks.

Disengage PTO, apply parking brake

and stop tractor engine before

dismounting tractor.

Keep hands, feet and clothing away from

moving parts.

Never transport faster than surface

conditions allow.

Display the SMV Emblem when

transporting with a tractor.

Make sure you are in compliance with

all local regulations regarding

transporting agriculture equipment on

public roads and highways. Consult

your local law enforcement agency for

further details.

Ensure that the Slow Moving Emblem

(SMV) and all reflectors and lights

required by the local highway and

transport authorities are in place and are

clean and visible by overtaking and

oncoming traffic.

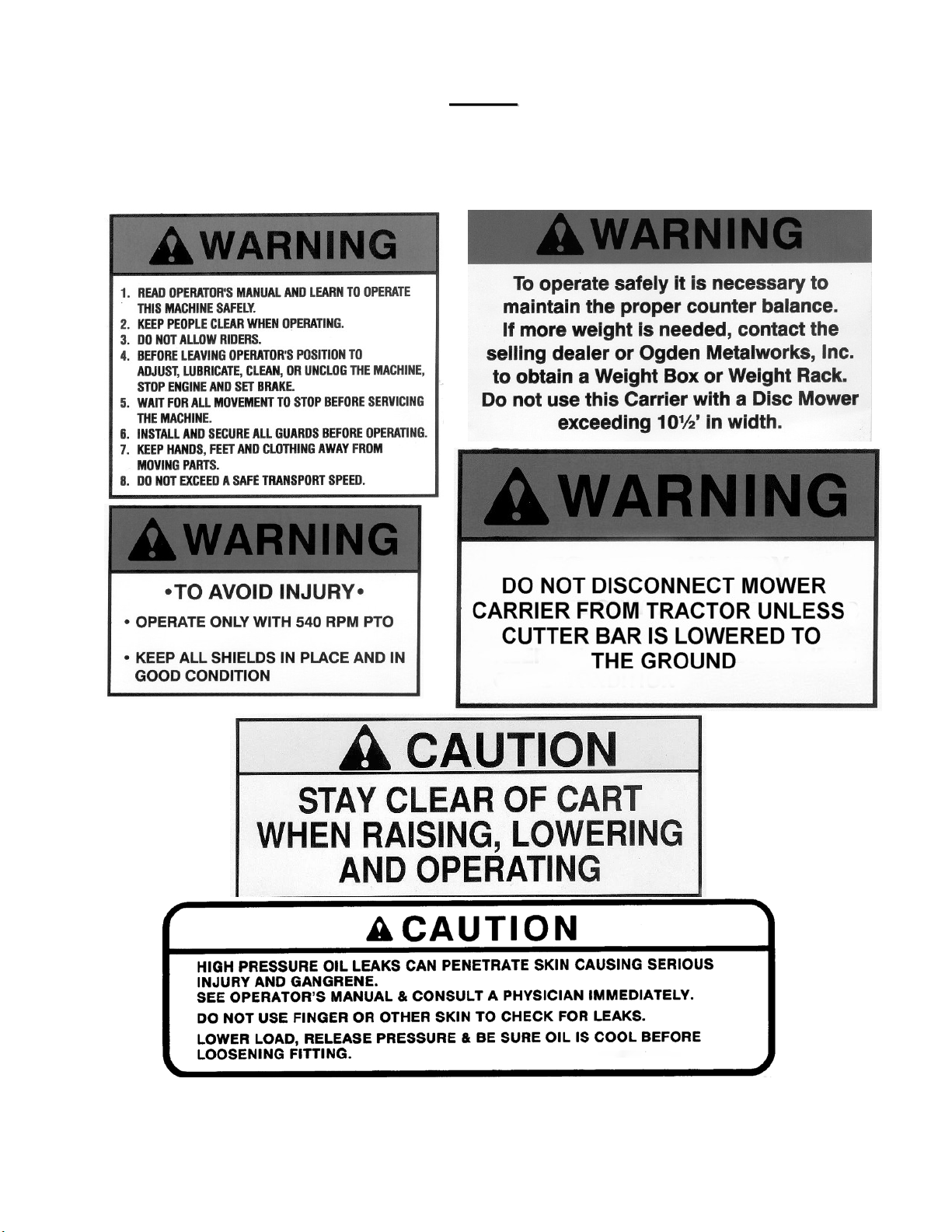

Be sure the Drivelines are properly

connected and that any quick

disconnects are locked before operation.

Do not disconnect Disc Mower Carrier

from tractor unless cutterbar is lowered

all the way to the ground.