Defender 2500 EN-1

TABLE OF CONTENTS

1. INTRODUCTION .........................................................................................................................................2

1.1. Safety Precautions ...................................................................................................................................2

1.2. Intended Use ............................................................................................................................................2

1.3. Overview of Parts and Controls ...............................................................................................................3

1.4. Control Functions .....................................................................................................................................3

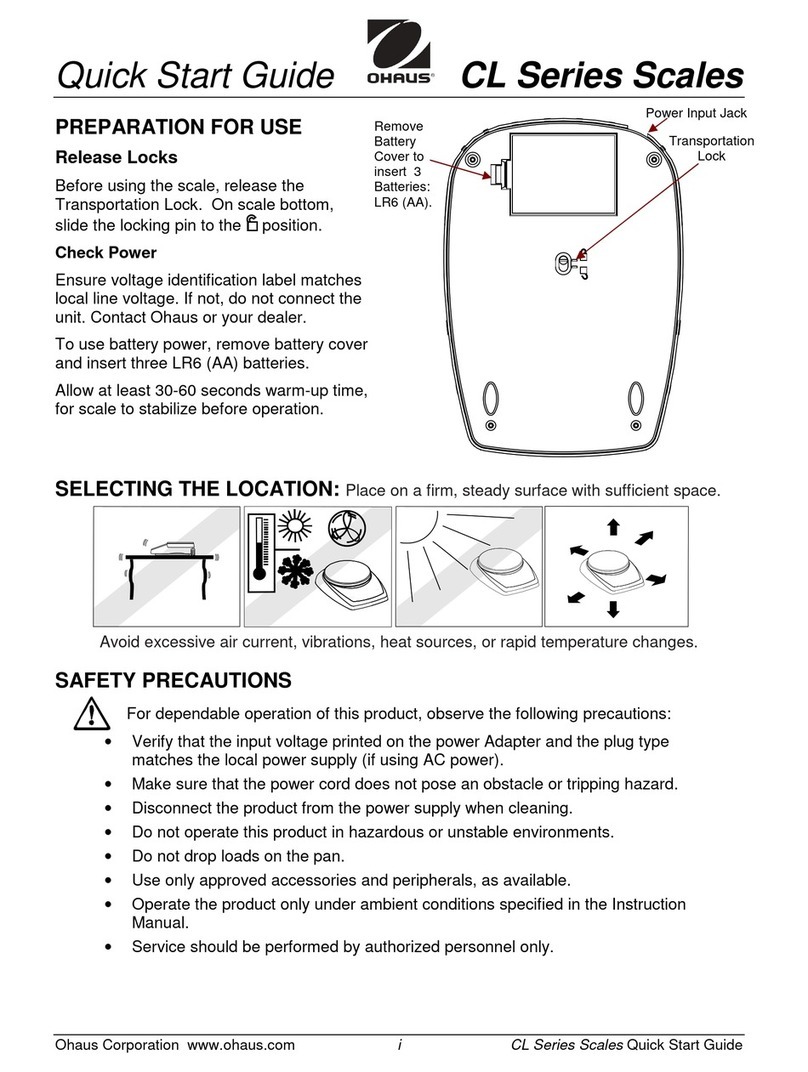

2. INSTALLATION...........................................................................................................................................5

2.1 Packing List ..............................................................................................................................................5

2.2 Setup ........................................................................................................................................................5

2.2.1 Power Supply Connection.................................................................................................................5

2.2.2 PC Connection..................................................................................................................................5

2.2.3 Column Mount Installation ................................................................................................................6

2.3 Selecting the Location ..............................................................................................................................7

3. OPERATION................................................................................................................................................8

3.1 Turning On/Off the Terminal ....................................................................................................................8

3.2 Setting the Display to Zero .......................................................................................................................8

3.3 Changing the Units of Measure................................................................................................................8

3.4 Printing Data.............................................................................................................................................8

3.5 Application Modes ....................................................................................................................................8

3.5.1 Weighing ...........................................................................................................................................8

3.5.2 Totalization........................................................................................................................................9

3.5.3 Dynamic Weighing / Display Hold.................................................................................................. 10

3.5.4 Peak Hold....................................................................................................................................... 12

3.5.5 Counting......................................................................................................................................... 12

4. MENU SETTINGS .................................................................................................................................... 13

4.1 Menu Navigation ................................................................................................................................... 13

4.1.1 User Menu (In segments) .............................................................................................................. 13

4.1.2 Button Navigation........................................................................................................................... 14

4.2 Calibration Menu ................................................................................................................................... 14

4.2.1 Initial Calibration............................................................................................................................. 15

4.2.2 Zero Calibration [ZErO] ................................................................................................................... 15

4.2.3 Span Calibration [SpaN] .................................................................................................................. 15

4.2.4 Linearity Calibration [LIN] ............................................................................................................... 16

4.2.5 GEO Code Adjustment [GEO] .......................................................................................................... 16

4.2.6 Calibration Test [C.test] ................................................................................................................. 17

4.2.7 End Cal [End] ................................................................................................................................. 17

4.3 Setup Menu ........................................................................................................................................... 17

4.4 Readout Menu....................................................................................................................................... 18

4.5 Unit Menu .............................................................................................................................................. 20

4.6 RS232 Menu ......................................................................................................................................... 20

4.7 Print Menu ............................................................................................................................................. 21

4.8 Lock Button Configuration..................................................................................................................... 24

5. LEGAL FOR TRADE................................................................................................................................ 25

5.1 Settings ................................................................................................................................................. 25

5.2 Verification............................................................................................................................................. 25

5.3 Sealing .................................................................................................................................................. 26

6. COMMUNICATION................................................................................................................................... 27

6.1 Terminal to Device Port Connections.................................................................................................... 27

6.1.1 USB (Type C) Port ......................................................................................................................... 27

6.1.2 RS232 Port..................................................................................................................................... 28

7. MAINTENANCE ....................................................................................................................................... 29

7.1 Cleaning ................................................................................................................................................ 29

7.2 Troubleshooting..................................................................................................................................... 29

7.3 Service Information ............................................................................................................................... 29

8. TECHNICAL DATA .................................................................................................................................. 30

8.1 Specifications ........................................................................................................................................ 30

8.2 Drawings and Dimensions .................................................................................................................... 31

8.3 Table of GEO Code Values................................................................................................................... 32

9. COMPLIANCE.......................................................................................................................................... 33

10. APPENDICES........................................................................................................................................... 35

10.1 MT Standard Continuous Output .......................................................................................................... 35

10.2 MT-SICS Commands ............................................................................................................................ 37

10.3 OHAUS Commands .............................................................................................................................. 38

10.4 OH-Continuous Print ............................................................................................................................. 39