8700-0001-000 Rev4

Table of Contents

1/ Definitions and Abbreviations

1.1 Definitions............................................................1

1.2 Abbreviations.......................................................1

2/ Scope

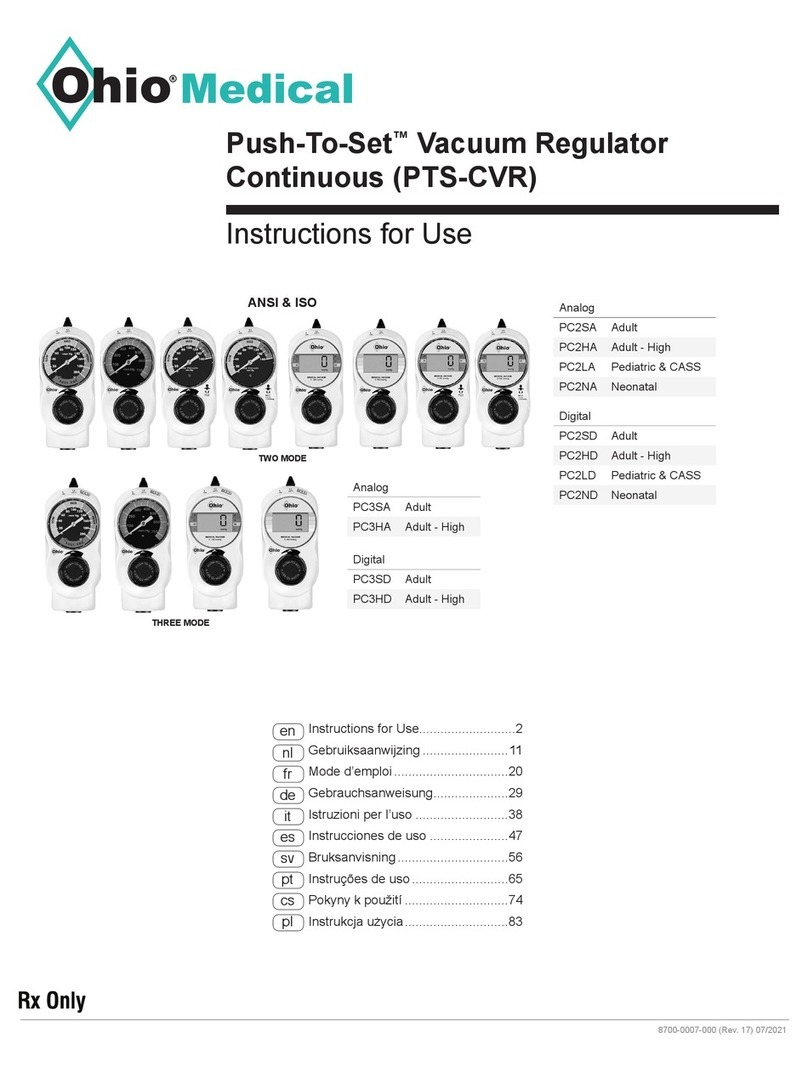

2.1 ANSI Vacuum Regulator......................................2

2.2 ISO Vacuum Regulator........................................2

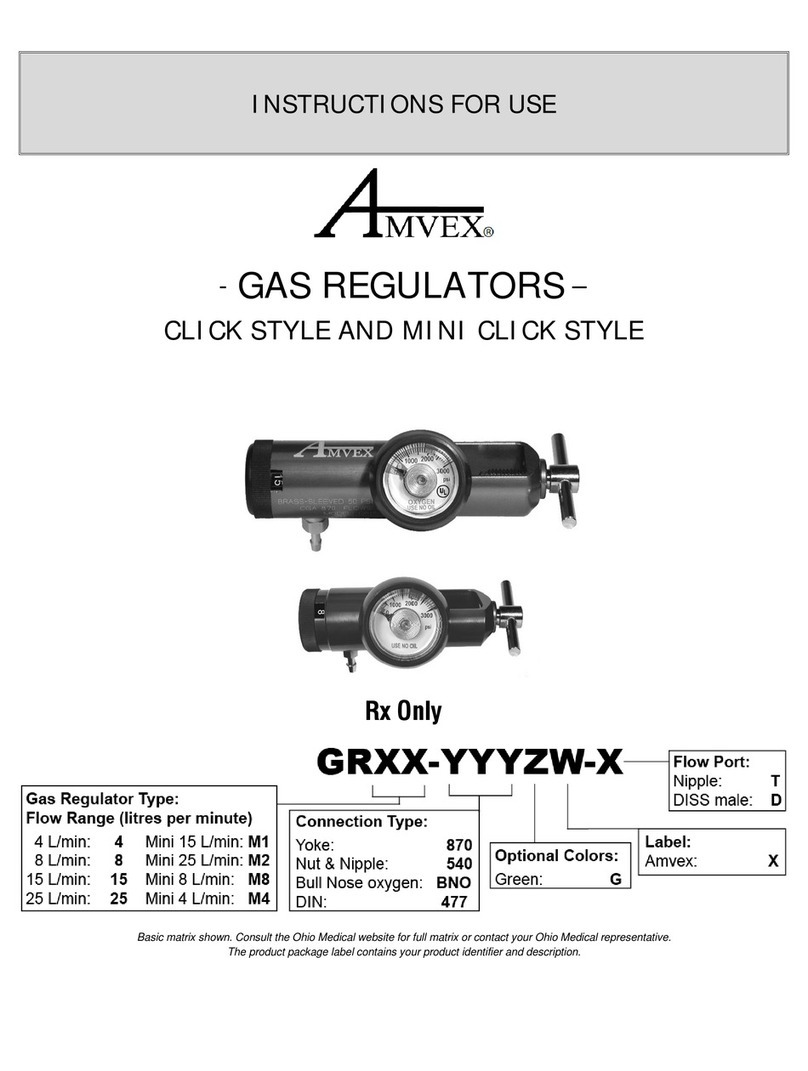

3/ Description and Specifications

3.1 Description...........................................................2

3.2 Specifications ......................................................3

4/ Operation

4.1 Equipment Setup.................................................4

4.1.1 Attaching the OST ......................................4

4.2 Mode Selection....................................................5

4.3 Setting the Suction Level.....................................5

4.4 Pre-Use Checkout Procedure..............................5

4.5 Patient Setup.......................................................6

5/ Cleaning and Sterilization

5.1 Cleaning ..............................................................6

5.1.1 Routine Exterior Cleaning...........................6

5.1.1.1 Approved Cleaning Solutions .........6

5.1.2 Internal Component Cleaning.....................7

5.1.2.1 Approved Flush Solutions...............7

5.1.3 Cold Flush Procedure.................................7

5.2 Disinfection..........................................................7

6/ Troubleshooting............................................8

7/ Service – Disassembly and Assembly

7.1 Service Tools and Equipment............................11

7.2 PTS-ISU Disassembly/Assembly ......................11

7.2.1 Disassembly.............................................11

7.2.2 Assembly..................................................12

7.3 Regulator Module..............................................13

7.3.1 Disassembly.............................................13

7.3.2 Assembly..................................................13

7.4 Timing and Flow Control Valves........................13

7.4.1 Disassembly.............................................13

7.4.2 Assembly..................................................13

7.5 Digital Gauge.....................................................13

7.5.1 Removal of Batteries................................13

7.5.2 Inserting Batteries

8/ Service Checkout Procedure

8.1 Setup.................................................................14

8.2 Push-To-Set™ Test............................................14

8.3 Leak Test – Supply Side....................................14

8.4 Flow Test ...........................................................14

8.4.1 Continuous Mode Flow Test.....................14

8.4.2 Intermittent Mode Flow Test .....................14

8.5 Timing Cycle Adjustment...................................15

8.6 Gauge Test........................................................15

8.7 Regulation Test..................................................16

8.8 Vacuum Buildup/Bleed-down Test – Intermittent

Mode........................................................................16

8.9 Bleed Test..........................................................16

8.10 Leak Test – Patient Side..................................16

9/ Maintenance

9.1 General Maintenance of Suction

Equipment ...............................................................17

9.2 Recommended Maintenance Schedule.............17

9.2.1 Maintenance Schedule............................17

9.3 Repair Policy .....................................................18

9.4 Technical Assistance .........................................18

9.5 Return Instructions ............................................18

9.6 Installation Procedure for Adapters/Probes

and Fittings..............................................................18

10/Ordering Information

10.1 Illustrated Parts...........................................19-20

TOC