2

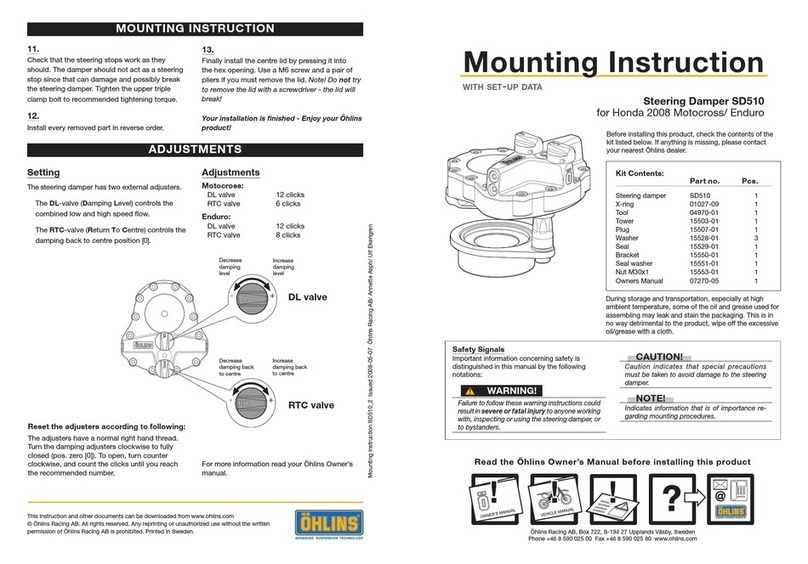

Safety signals

Important information concerning safety is

distinguished in this manual by the

following notations:

The Safety alert symbol means:

Caution! Your safety is involved.

WARNING!

Failure to follow warning instructions

could result in severe or fatal injury

to anyone working with, inspecting or

using the suspension, or to bystanders.

CAUTION!

Caution indicates that special pre-

cautions must be taken to avoid dam-

age to the suspension.

NOTE!

This indicates information that is of

importance with regard to procedures.

Introduction

All of Öhlins advanced suspension products are

adapted to the brand and model. This means that

length, travel springaction and damping charac-

teristics, are tested individually just for the

motorcycle that you have decided to fit with

Öhlins suspension.

Before installation

Öhlins Racing AB can not be held responsible for

any damage whatsoever to shock absorber or

vehicle, or injury to persons, if the instructions for

fitting and maintenance are not followed exactly.

Similarly, the warranty will become null and void

if the instructions are not adhered to.

© Öhlins Racing AB.

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Öhlins Racing AB is prohibited.

Printed in Sweden.

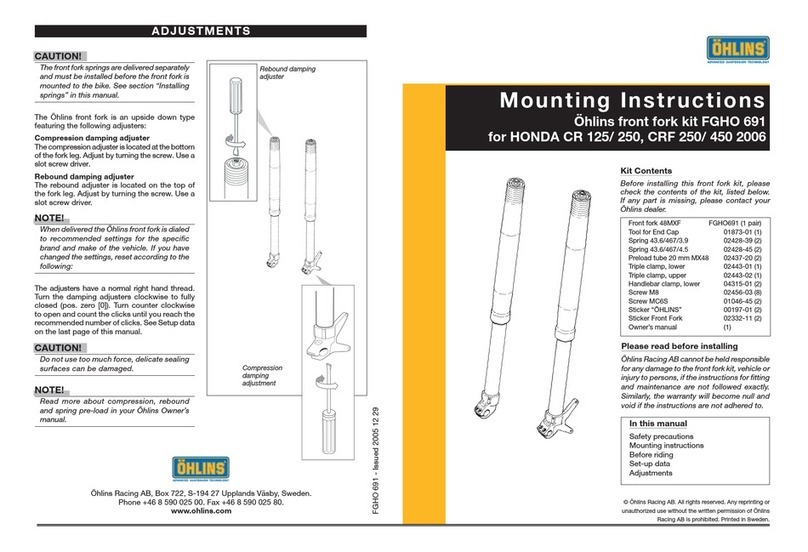

WARNING!

1. Installing a front fork, that is not approved by

the vehicle manufacturer, may affect the stability

of your vehicle. Öhlins Racing AB cannot be held

responsible for any personal injury or damage

whatsoever that may occur after fitting the front

fork. Contact an Öhlins dealer or other qualified

person for advice.

2. Please study and make certain that you fully

understand all the mounting instructions and

the owners manuals before handling this front

fork kit. If you have any questions regarding

proper installation procedures, contact an

Öhlins dealer or other qualified person.

3. The vehicle service manual must be referred

to when installing the Öhlins front fork.

NOTE

Öhlins products are subject to continual improve-

ment and development. Consequently, although

these instructions include the most up-to-date

information available at the time of printing, there

may be minor differences between your suspen-

sion and this manual. Please consult your Öhlins

dealer if you have any questions with regard to

the contents of the manual.

Contents

Safety signals ................................................ 2

Introduction ................................................... 2

Tuning the suspension ................................... 3

Design ........................................................... 3

Settings ......................................................... 4

Setting the spring preload ............................. 4

Fine tuning the bike ....................................... 5

Preload adjustment ....................................... 7

Changing springs .......................................... 9

Technical information ................................... 10

Exploded drawing ....................................... 11

General handling set-up .............................. 12

Maintenance ................................................ 13