43502101TH Rev.1 4 /

Oki Data CONFIDENTIAL

1. CONFIGURATION ..................................................................................... 6

1.1 System Configuration ........................................................................ 6

1.2 Printer Configuration .......................................................................... 7

1.3 Optional Configuration ....................................................................... 8

1.4 Specification .................................................................................... 10

1.5 Safety Standards ............................................................................. 12

1.5.1 Certification Label .................................................................................... 12

1.5.2 Warning Label ......................................................................................... 12

1.5.3 Warning/Caution Marking ........................................................................ 13

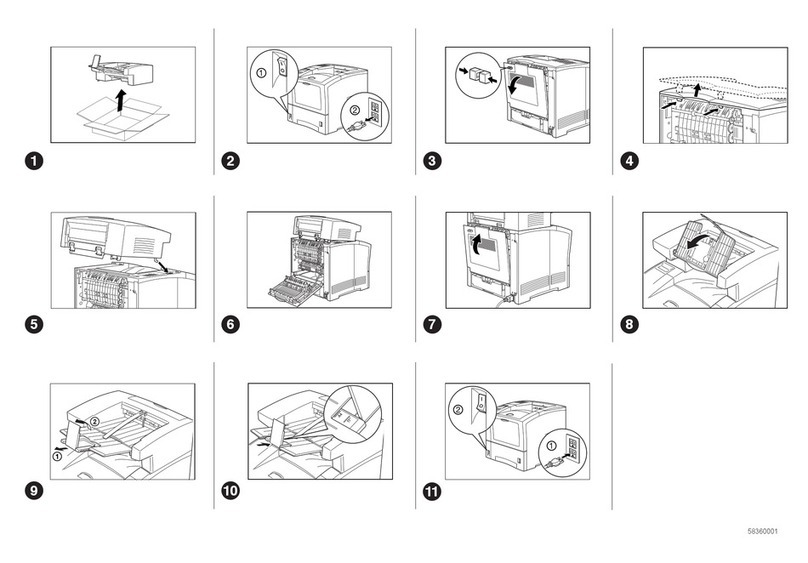

2. PARTS REPLACEMENT ......................................................................... 14

2.1 Precautions for Parts Replacement ................................................. 14

2.2 Parts Layout..................................................................................... 16

2.3 How to Change Parts....................................................................... 19

2.3.1 Upper Cover Assy ................................................................................... 20

2.3.2 LED Head ................................................................................................ 21

2.3.3 Operator Panel Assy ............................................................................... 22

2.3.4 Lower Base Unit ...................................................................................... 23

2.3.5 Pulse Motor (Main/Drum) ........................................................................ 24

2.3.6 Pulse Motor (Registration) ....................................................................... 25

2.3.7 CLUTCH .................................................................................................. 26

2.3.8 Face Up Stacker Assy ............................................................................. 27

2.3.9 Eject Roller Assy ..................................................................................... 28

2.3.10 Motor Assy............................................................................................... 29

2.3.11 Hopping Roller Shaft Assy....................................................................... 30

2.3.12 Stacker Cover Assy ................................................................................. 31

2.3.13 Registration Roller ................................................................................... 32

2.3.14 Roller Transfer Assy ................................................................................ 33

2.3.16 Back-up Roller ......................................................................................... 35

2.3.17 Sensor Plate (Inlet) .................................................................................. 36

2.3.18 Sensor Plate (Outlet), Sensor Wire Assy ................................................ 37

2.3.19 Manual Feed Guide Assy ........................................................................ 38

2.3.20 Sensor Plate (Paper Supply) ................................................................... 39

2.3.21 Main control board ................................................................................... 40

2.3.22 Power Supply Board and High Voltage/Sensor Board ............................ 41

2.3.23 Cassette Guide L Assy ............................................................................ 42

2.3.24 Cassette Guide R Assy ........................................................................... 43

3. ADJUSTMENT ......................................................................................... 44

3.1 Maintenance Modes and Functions ................................................. 44

3.1.1 User Maintenance Mode (Administrator Menu) ....................................... 44

3.1.2 System Maintenance Mode (System Maintenance Menu) ...................... 46

3.1.3 EEPROM Initial Setting Range for Events............................................... 48

3.2 Adjustment When Replacing a Part ................................................. 49

4. PERIODICAL MAINTENANCE ............................................................... 50

4.1 Periodical Replacement Parts ......................................................... 50

4.2 Cleaning........................................................................................... 50

4.2.1 Cleaning of LED Lens Array .................................................................... 50

4.2.2 Cleaning Page Function .......................................................................... 52

CONTENTS