43856301TH Rev.3 4 /

Oki Data CONFIDENTIAL

Index

1. Configuration...........................................................................6

1.1 System configuration............................................................................................7

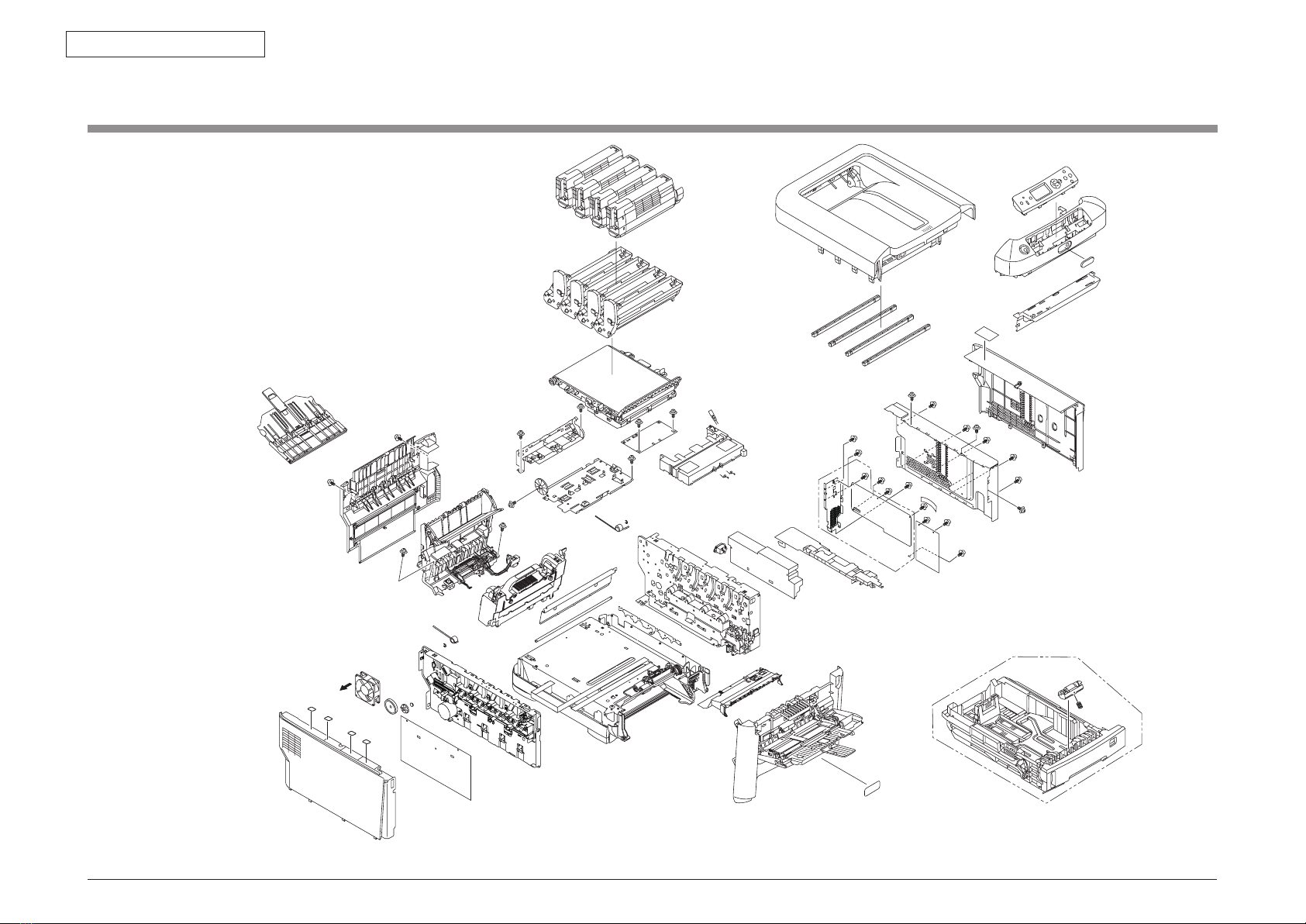

1.2 The Configuration of printer..................................................................................8

1.3 Optional parts.......................................................................................................9

1.4 Specifications .....................................................................................................10

1.5 Specification of interface ....................................................................................13

1.5.1 Specification of USB interface ....................................................................13

1.5.1.1 General of USB interface.....................................................................13

1.5.1.2 Connector and cable of USB interface.................................................13

1.5.1.3 USB interface signal............................................................................13

1.5.2 Specification of network interface...............................................................14

1.5.2.1 General of network interface................................................................14

1.5.2.2 Connector and cable of network interface...........................................14

1.5.2.3 Signal of network interface ..................................................................14

1.5.3 Specification of parallel interface................................................................15

1.5.3.1 General of parallel interface.................................................................15

1.5.3.2 Connector and cable of parallel interface ............................................15

1.5.3.3 Parallel interface level..........................................................................15

1.5.3.4 Signal of interface................................................................................15

2. Operating instructions..........................................................16

2.1 Electrophotographic processing mechanism......................................................17

2.2 Printing process..................................................................................................21

3. Set up .....................................................................................32

3.1 Notes and precautions........................................................................................33

3.2 Unpack method ..................................................................................................34

3.3 Setting method ...................................................................................................35

Set space................................................................................................................35

3.4 List of equipments and accessories ...................................................................36

3.5 Assembling method............................................................................................37

3.5.1 Assemble the main body of the printer .......................................................37

3.5.2 Cable connect.............................................................................................43

3.5.3 Optional part installation and confirmation..................................................45

3.6 Setting content print (Configuration)...................................................................56

3.7 Connecting method ............................................................................................57

3.8 User used Paper confirmation............................................................................59

4. Component replacement......................................................60

4.1 Precautions on component replacement............................................................61

4.2 Method of component replacement....................................................................63

4.2.1 Belt unit.......................................................................................................63

4.2.2 Fuser unit....................................................................................................64

4.2.3 Left side cover.............................................................................................64

4.2.4 Right side cover..........................................................................................65

4.2.5 Faceup tray ................................................................................................65

4.2.6 Rear cover...................................................................................................66

4.2.7 LED Assy/ LED Assy spring........................................................................66

4.2.8 Control PCB................................................................................................67

4.2.9 Print engine controller PCB.........................................................................68

4.2.10 Top cover Assy............................................................................................69

4.2.11 Top cover ....................................................................................................70

4.2.12 Control panel Assy .....................................................................................70

4.2.13 Board PRG/ LCD........................................................................................71

4.2.14 Frame panel Assy.......................................................................................72

4.2.15 Low voltage power supply/Low voltage FAN/ Hopping motor/

Fuse motor..................................................................................................73

4.2.16 Guide eject Assy/ Color resist Assy/ Board-PRY........................................74

4.2.17 FAN(Fuser) / Belt motor/ High-voltage board/ Cover open switch..............75

4.2.18 MPT Assy...................................................................................................75

4.2.19 Feeder unit/ Board-RSF/MPT hopping roller/ Frame Assy separator/

Cover front ..................................................................................................76

4.2.20 Board-PRZ liftup motor/ Hopping motor/ Solenoid/Paper end sensor........77

4.2.21 Feed roller...................................................................................................78

4.2.22 Shaft eject Assy (FU)/ Shaft eject Assy(FD/ Eject sensor..........................79

4.3 Oiling spots.........................................................................................................80