CONTENTS

1. OUTLINE.....................................................................................................1

2. TOOLS........................................................................................................1

3. CIRCUIT DESCRIPTION............................................................................2

3.1 Outline.....................................................................................................................2

3.2 CPU and Memory....................................................................................................4

3.3 Reset Control...........................................................................................................6

6.1 HUK PCB ............................................................................................................

............................................................................................................

............................................................................................................

6.2 P2H PCB 37

41

46

6.3 P6L PCB

3.4 EEPROM Control.....................................................................................................7

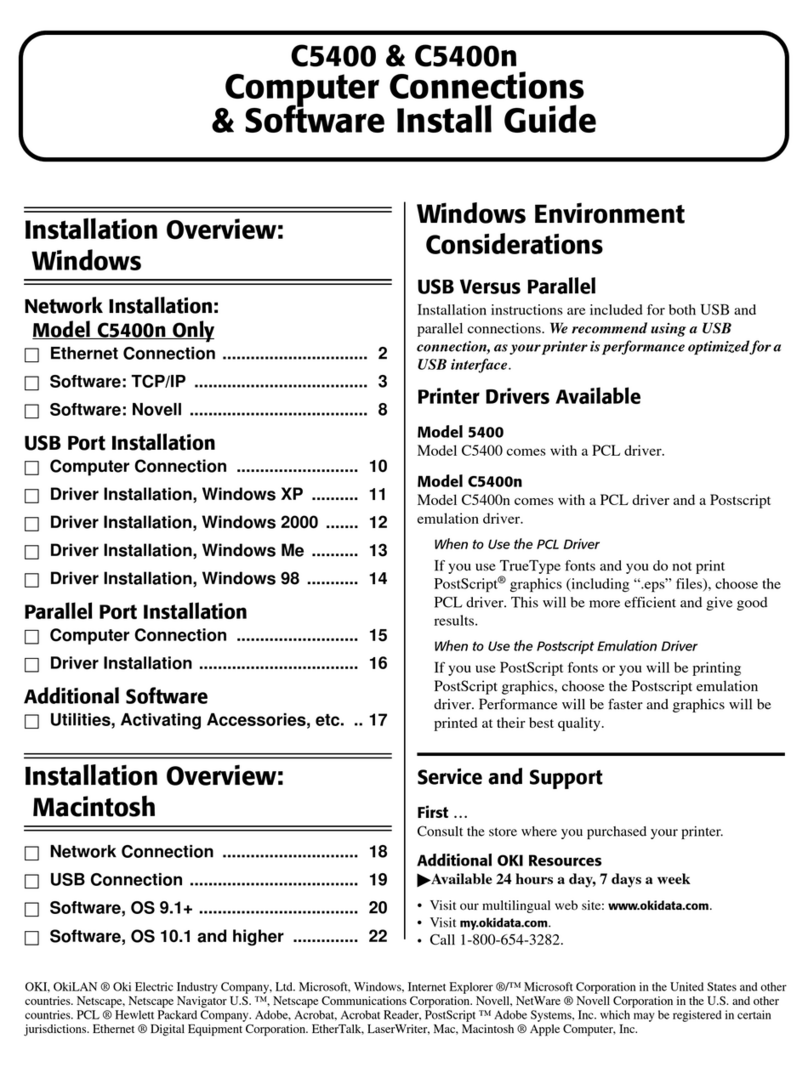

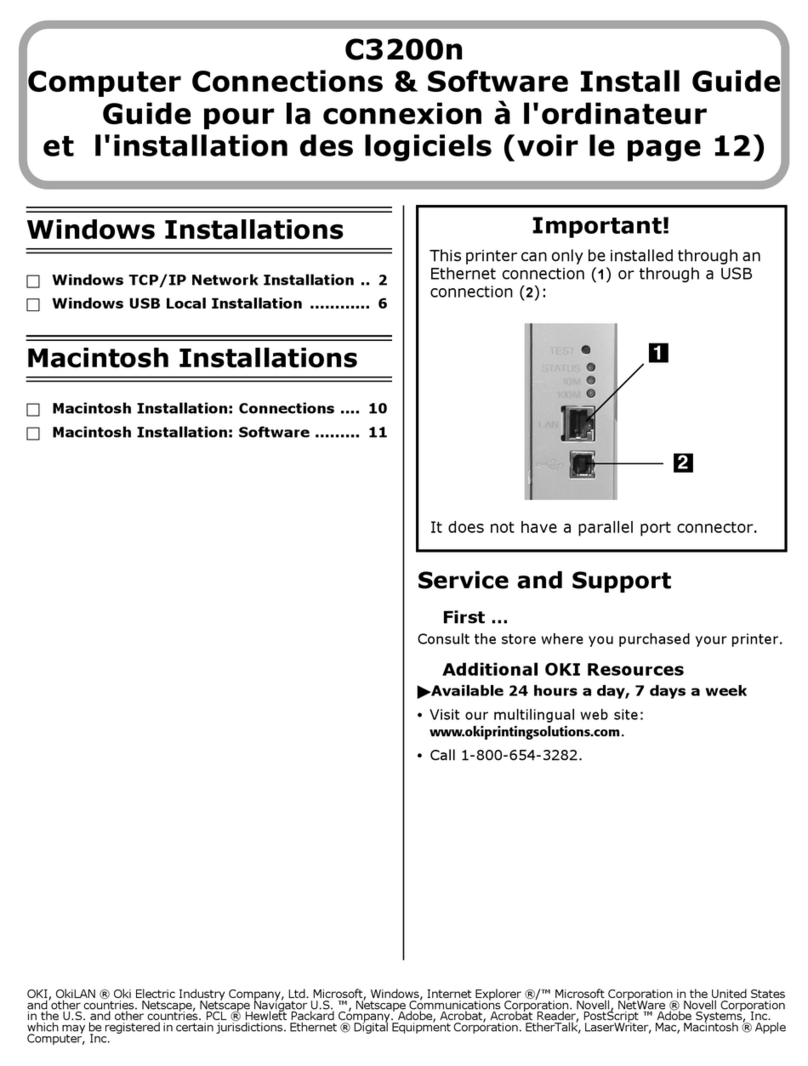

3.5 Centronics Parallel Interface....................................................................................8

3.6 Front Operator Panel...............................................................................................9

3.7 LED Head Control.................................................................................................10

3.8 Motor and clutch control........................................................................................12

3.9 Fuser Temperature Control....................................................................................14

3.10Sensor Control.......................................................................................................17

3.11Cover Open...........................................................................................................18

3.12Power Supply Part.................................................................................................19

4. TROUBLESHOOTING..............................................................................21

4.1 Troubleshooting Table............................................................................................21

4.2 Troubleshooting Flowchart.....................................................................................23

5. CIRCUIT DIAGRAM..................................................................................27

6. COMPONENT PARTS LIST AND LAYOUT.............................................. 36