CONTENTS

1. CONFIGURATION..................................................................................... 1 - 1

1.1 System Configuration ........................................................................ 1 - 1

1.2 Printer Configuration.......................................................................... 1 - 3

1.3 Optional Configuration....................................................................... 1 - 4

1.4 Specification ...................................................................................... 1 - 7

1.5 Safety Standards ............................................................................... 1 - 9

1.5.1 Certification Label.................................................................................... 1 - 9

1.5.2 Warning Label .........................................................................................1 - 9

1.5.3 Warning/Caution Marking ........................................................................ 1 - 10

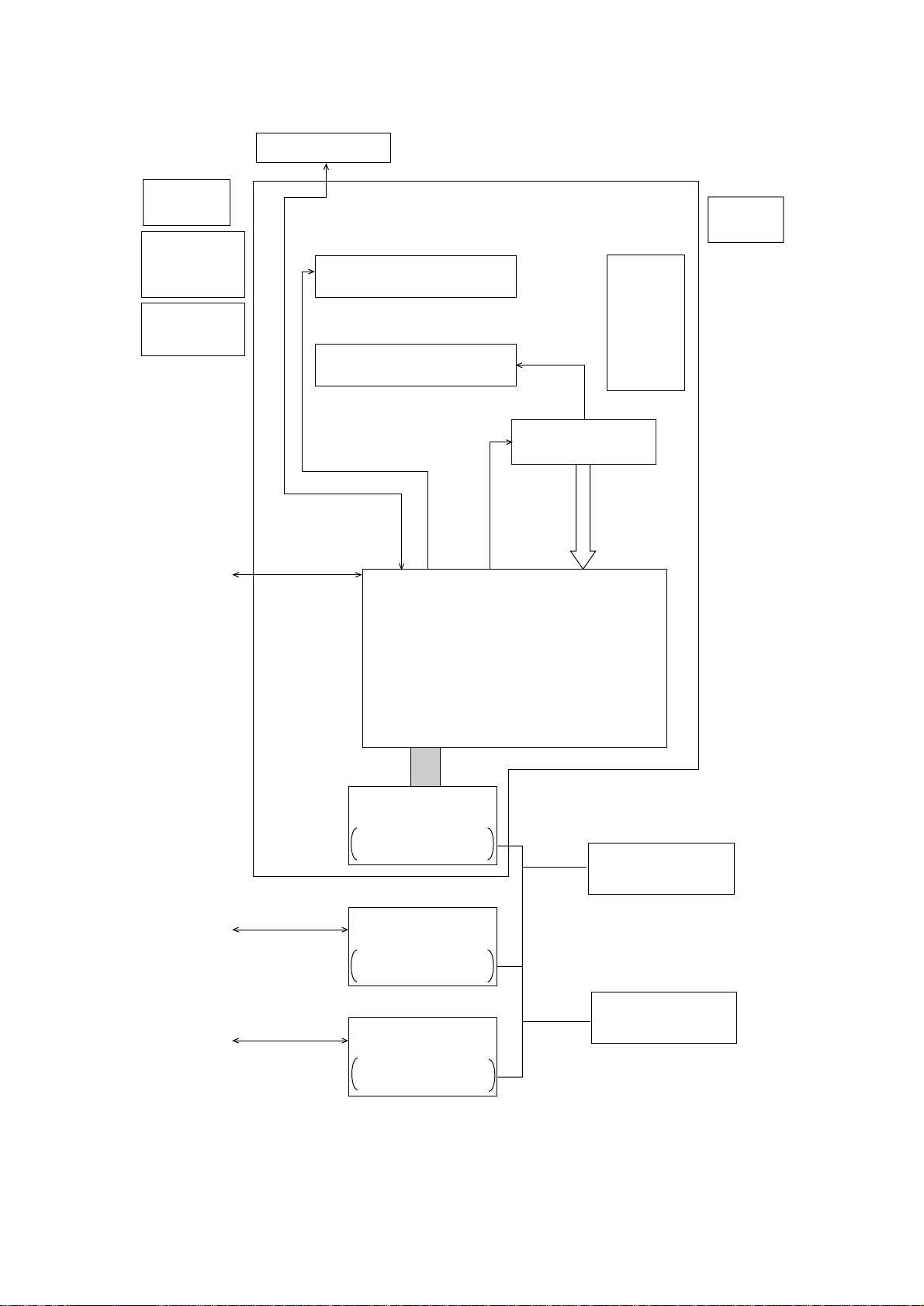

2. OPERATION DESCRIPTION .................................................................... 2 - 1

2.1 Main Control Board............................................................................ 2 - 3

2.2 Power Supply/Sensor Board.............................................................. 2 - 4

2.3 Electrophotographic Process............................................................. 2 - 6

2.3.1 Electrophotographic Process Mechanism ............................................... 2 - 6

2.3.2 Electrophotographic Process .................................................................. 2 - 9

2.3.3 Process Operation Descriptions .............................................................. 2 - 12

2.3.4 Revision of LED Head Illumination .......................................................... 2 - 22

2.4 Paper Jam Detection ......................................................................... 2 - 26

2.5 Cover Open ....................................................................................... 2 - 28

2.6 Toner Low Detection.......................................................................... 2 - 29

3. PARTS REPLACEMENT........................................................................... 3 - 1

3.1 Precautions for Parts Replacement................................................... 3 - 1

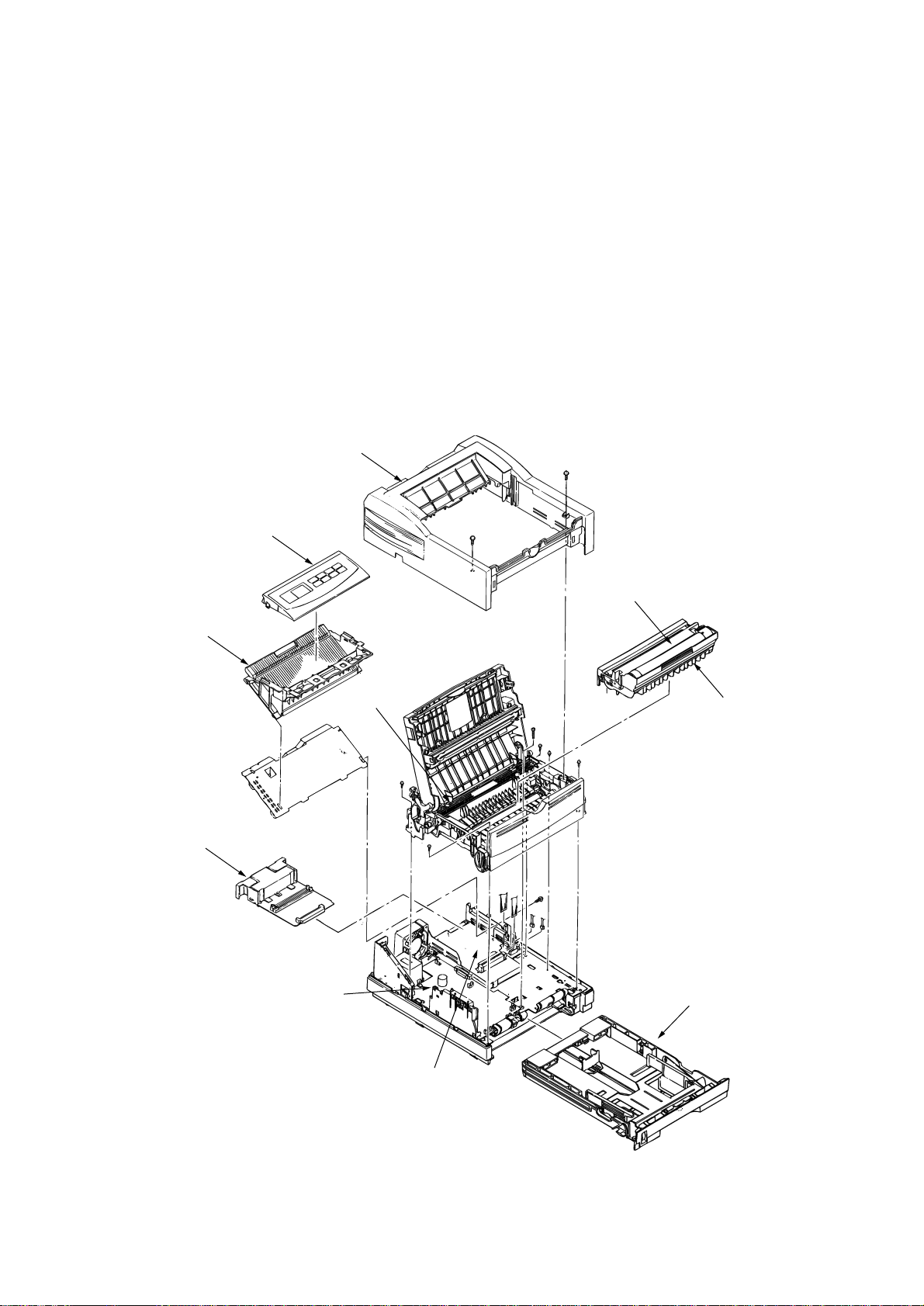

3.2 Parts Layout....................................................................................... 3 - 3

3.3 How to Change Parts......................................................................... 3 - 6

3.3.1 Upper Cover Assy ...................................................................................3 - 7

3.3.2 LED Head ................................................................................................ 3 - 8

3.3.3 Operator Panel Assy ............................................................................... 3 - 9

3.3.4 Lower Base Unit ...................................................................................... 3 - 10

3.3.5 Pulse Motor (Main/Drum) ........................................................................ 3 - 11

3.3.6 Pulse Motor (Registration)....................................................................... 3 - 12

3.3.7 Face Up Stacker Assy............................................................................. 3 - 13

3.3.8 Eject Roller Assy ..................................................................................... 3 - 14

3.3.9 Motor Assy .............................................................................................. 3 - 15

3.3.10 Hopping Roller Shaft Assy ...................................................................... 3 - 16

3.3.11 Stacker Cover Assy ................................................................................. 3 - 17

3.3.12 Registration Roller ................................................................................... 3 - 18

3.3.13 Roller Transfer Assy ................................................................................3 - 19

3.3.14 Fusing Unit .............................................................................................. 3 - 20

3.3.15 Back-up Roller .........................................................................................3 - 21

3.3.16 Sensor Plate (Inlet)..................................................................................3 - 22

3.3.17 Sensor Plate (Outlet) ............................................................................... 3 - 23

3.3.18 Manual Feed Guide Assy ........................................................................ 3 - 24

3.3.19 Sensor Plate (Paper Supply) ................................................................... 3 - 25

3.3.20 M5E-PCB ................................................................................................ 3 - 26

3.3.21 Transformer............................................................................................. 3 - 27

3.3.22 Power Supply/Sensor Board and Contact Assy ...................................... 3 - 28