FS-519/PK-515/OT-602

GeneralMaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 3.0 Jan. 2008

ii

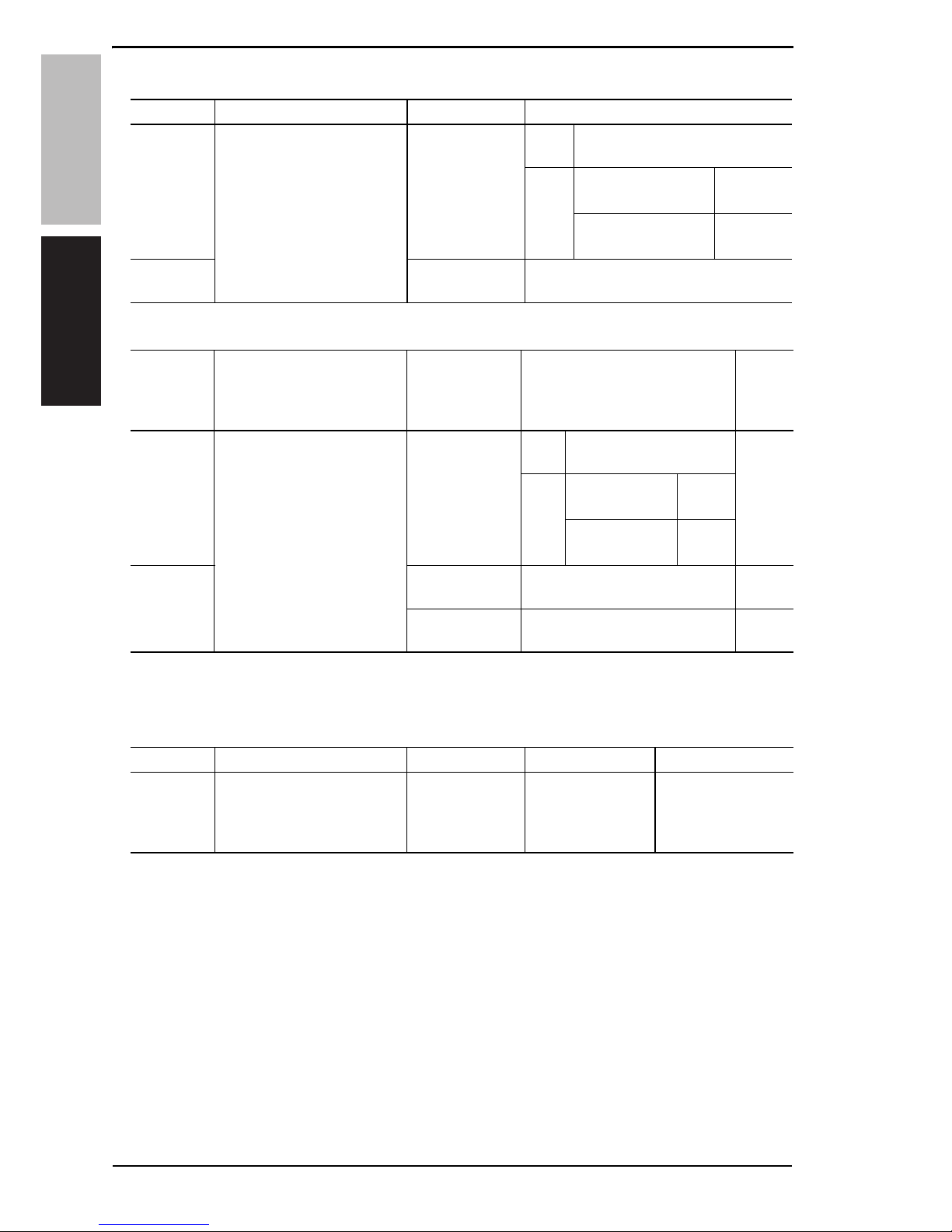

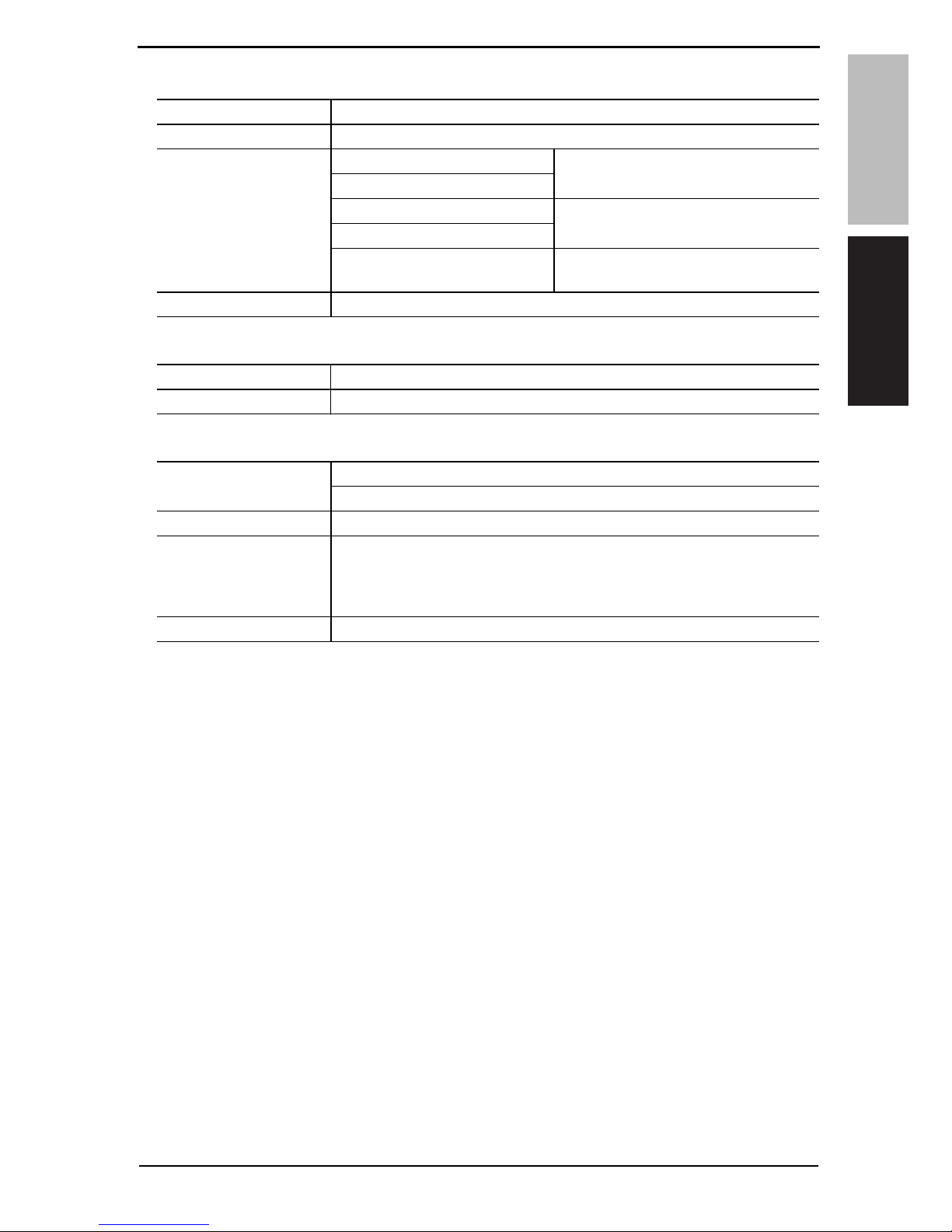

4.4.14Height and angle adjustment of stand tablefor d-Color MF350 Family ..... 40

4.4.15Height and angle adjustment of stand table for d-Color MF450 ................ 42

4.4.11Trayunit.......................................................................................................31

4.4.12Finisher unit................................................................................................34

4.4.13Changing the height of the stand table only for d-Color MF350 /

d-Color MF250 / d-Color MF201Plus ........................................................ 35

4.4.16Stapler unit..................................................................................................44

4.4.17Punch kit (PK-515): Option.........................................................................45

4.4.18Exit roller motor/Storage paddle drive clutch/Exitupper roller/

Storage paddle...........................................................................................46

4.4.19Exit paddle drive clutch/Exit lowerroller.....................................................51

4.4.20 Aligningsection...........................................................................................54

4.4.21 Elevator motor/Timing belt..........................................................................57

4.4.22 Shutter drive gear.......................................................................................63

4.4.23 Duplex guide solenoid................................................................................64

4.4.24 FScontrol board.........................................................................................66

Adjustment/Setting

5.Howto use the adjustment section.......................................................................67

6.SensorCheckfor d-Color MF350 Family ............................................................. 68

6.1Check procedure................................................................................................68

6.1.1Sensorcheck screen..................................................................................68

6.1.2Sensorcheck list.........................................................................................69

7.SensorCheckfor d-Color MF450 ......................................................................... 70

7.1Check procedure................................................................................................70

8.Finisher operations...............................................................................................72

8.1CB-FN adjustment..............................................................................................72

8.1.1Finisher Check............................................................................................72

8.1.2Punch Regist Loop Size.............................................................................74

8.1.3Punch Horizontal Position...........................................................................75

8.2Punch option setting...........................................................................................76

9.Mechanical adjustment.........................................................................................77

9.1Punch hole device adjustment (PK-510 / PK-515).............................................77

9.2Staple position adjustment.................................................................................78

9.3Staple home position sensor position adjustment..............................................80

9.4Adjustment of clearance between stapler and FDstopper.................................81

Troubleshooting for d-Color MF350 / MF250 / MF201Plus

10.Jamdisplay.........................................................................................................83

10.1Misfeeddisplay.................................................................................................83

10.1.1Misfeed display resetting procedure.........................................................83

10.2Sensor layout....................................................................................................84