27

fig.26

Important instructions for installation and

operation

•The electrical installation of this heater must be

approved by your local electricity company.

•The installation must be carried out by a competent

electrician in accordance with I.E.E. regulations.

•Local safety regulations must also be adhered to.

•Following tests must be carried out before

commissioning the heater

-Insulation test with a voltage of at least 500V.

The dielectric resistance must be at least

0,5MOhm.

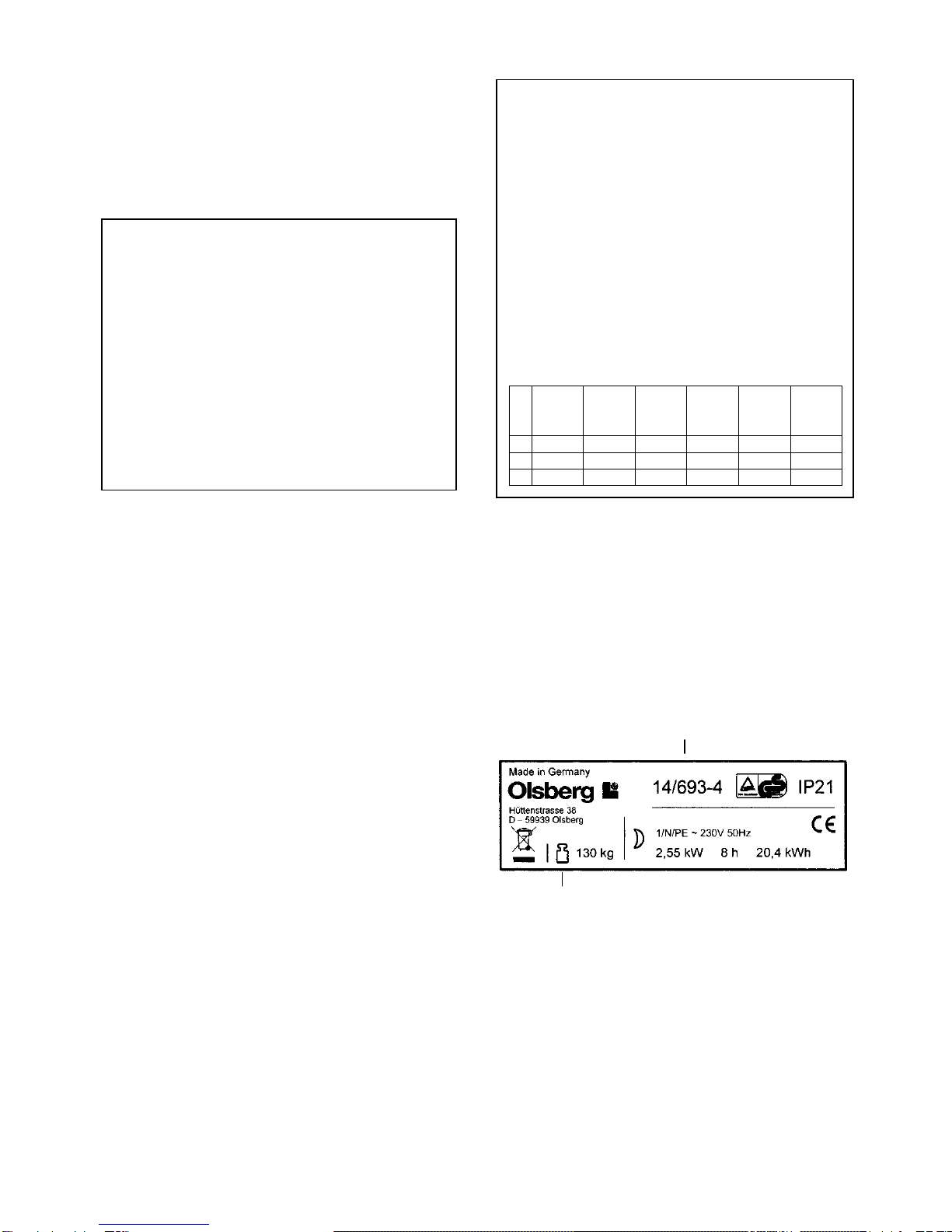

-The electrical installer must measure the power

draw of the elements. This can be done using a

kW and time measurement or alternatively by

measuring the cold element resistance. The

value is to be compared with that of the rating la-

bel or in the ‘Technical Data’ Section.

•The storage heater is only to be used in rooms

where neither explosive gases (e.g. from floor-

sealant), nor inflammable dust is present!

•Electrical appliances conform to valid safety regu-

lations. Repairs and service to electrical appliances

must only be carried out by a competent electri-

cian. Improper repair can mean distinct danger to

the user.

•As the surfaces of the heater cabinet get hot in

use, flammable or other objects presenting a dan-

ger of fire must not be placed on, or near the

heater.

Do not, therefore, place any wooden objects,

clothes or washing, newspapers, blankets or the

like on or over the heater and do not put any

pieces of furniture made of inflammable materials,

nor spray tubes or similar objects closer than 25cm

in front of, or on the heater, especially not in front

of the air-outlet grille.

•It is important to remember that the surfaces of the

heater can reach temperatures in excess of 80°C

(60K) during operation.

•The storage heater is designed to need very little

maintenance.

•Cleaning and maintenance intervals are very de-

pendent on the respective circumstances sur-

rounding installation and operation. We recom-

mend that the first inspection take place at the lat-

est before the second heating period. Further

maintenance intervals can then be set according to

individual circumstances.

•Heater surfaces must not be cleaned with any

scouring or soft-scrub materials. Only use normal

household cleaning liquids.

•Heaters that have already been in operation or

have been taken apart and repositioned must be

re-installed according to these instructions. The

commissioning tests described on this page must

also be carried out.

-any insulation parts which are, or seem to be,

damaged or have changed properties which

could influence their function and safety, must

be replaced by new ones.

•Packaging materials, replaced parts and decom-

missioned appliances and/or parts must be dis-

posed of correctly.

•This heater is not intended for operating by per-

sons (including children), with reduced physical,

sensory or mental abilities or for lack of experience

and/or for lack of knowledge to be used it by a per-

son responsible for their security is supervised or

received from instructions like the heater to use.

Children should be supervised, in order to guaran-

tee that they do not play with the heater.