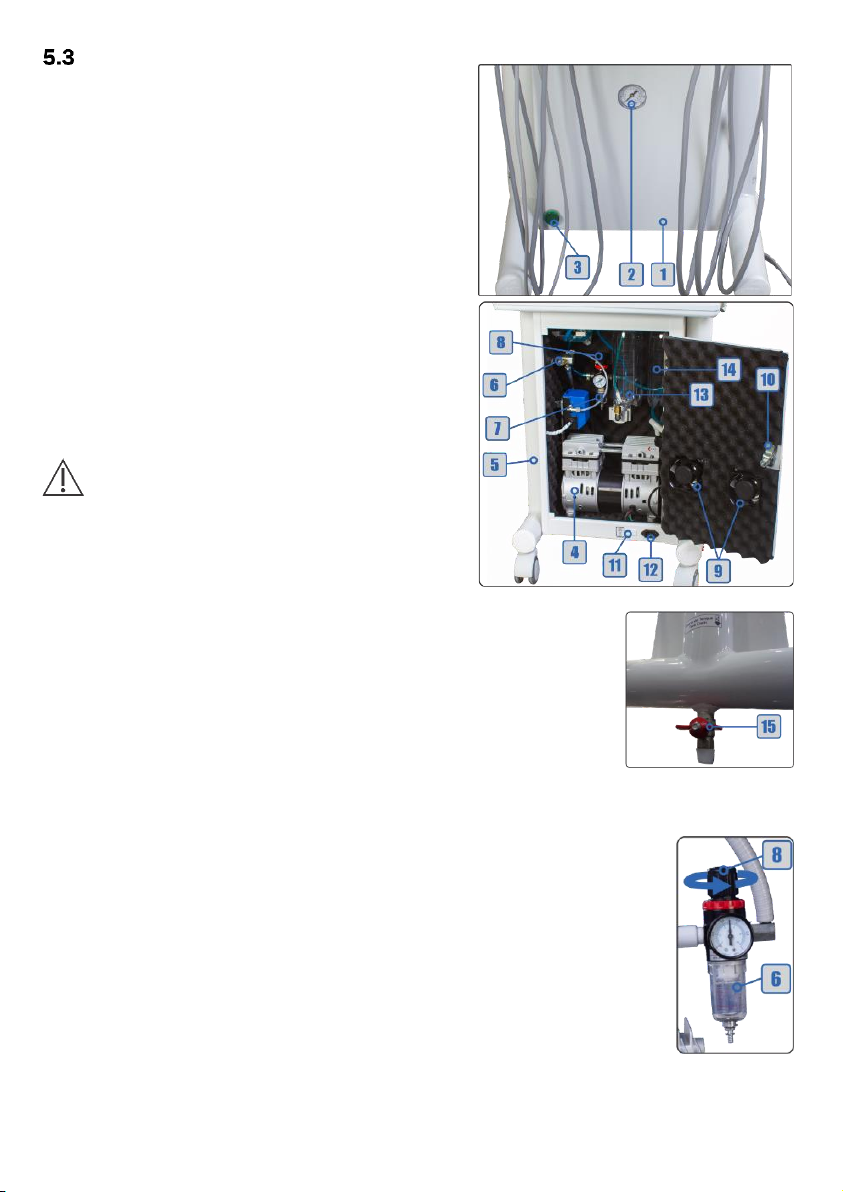

10

- Ultrasonic Scaler with/without LED Light

The ultrasonic scaler has an ultrasonic

generator electronic board that, through the

Piezoelectric System, provides the tip vibration,

giving a high-frequency condition. When the

ultrasonic scaler is triggered, it starts the tip

vibration, activates the LED and opens the water

passage for cooling. Vibration power and water

flow control for cooling can be adjusted through

individual controls.

This handpiece was developed for use in

dental applications, such as scarification, root

planning, root canal treatment, cavity and

periodontal preparation. These tips come with

the ultrasonic scaler: GD1, PD1 and PD3.

Technical Features:

- Frequency: 28 KHz ± 3 KHz;

- Power supply: 24 VCA;

- Output force (half-displacement): <2N;

- Power Rating: 3 to 20 W;

- Operation mode: Continuous;

- Tip vibration displacement: ≤100 μm.

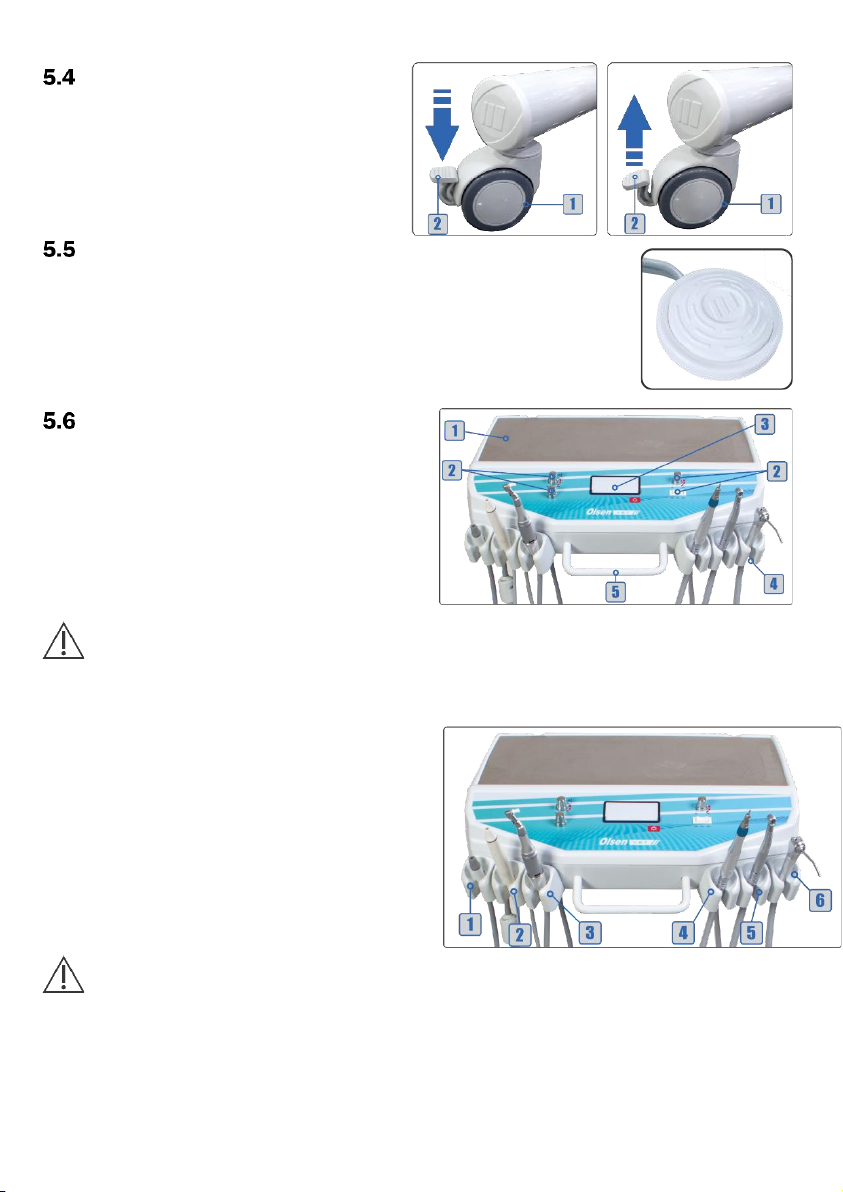

For the ultrasonic scaler use it is necessary to connect the transducer (1) to the

terminal (3) and install the ultrasonic tip on the transducer.

To attach the transducer to the terminal: Align the adjustment indicators (2) of

the two parts and carefully insert them.

To install the scaler tips: Insert the tip into the transducer by threading it carefully, then insert the Torque

wrench (4) into the tip and then rotate it clockwise until it is tight. To remove the tip, turn it counterclockwise with

the Torque wrench.

After installing the tip, check for leakage between the transducer (1) and the terminal (3).

To install a file adapter (not supplied with the scaler): Attach the adapter to the transducer and screw it

gently. Use the Endo wrench (5) to lock. Insert the file into the tip of the adapter, thread the tip and then use the

Endo wrench (5) to tighten. To remove the adapter, use the Endo wrench to loosen it and then carefully unscrew.

To activate the ultrasonic scaler: Press the progressive foot pedal (section 5.5).

To adjust the vibration power: Turn the control knob (6) until the desired power is reached.

To toggle functions: Push the control knob (6) in direction of the table for "GP" function (General and Perio).

Pull the knob gently in the opposite direction of the table for "E" (Endo) function (this function is not available to

V2 Scaler without LED light).

To adjust the water flow: Turn the adjust knob (7) until the desired flow is reached.

The selection between General and Perio / Endo function is not available to V2 Scaler without LED

light.

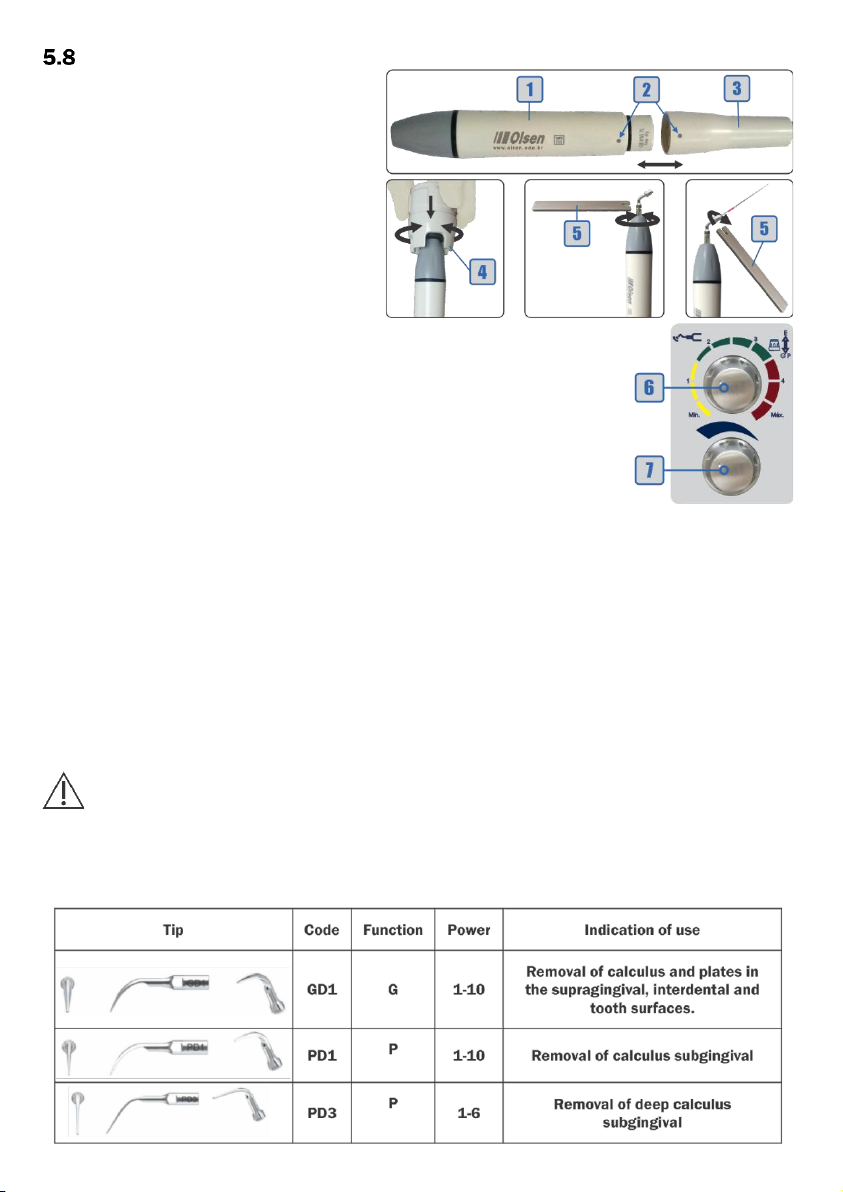

5.8.1 - Ultrasonic Scaler Tips

The tips GD1, PD1 and PD3 accompany the scaler. The power and application information for each tip is

available in the table below.