10

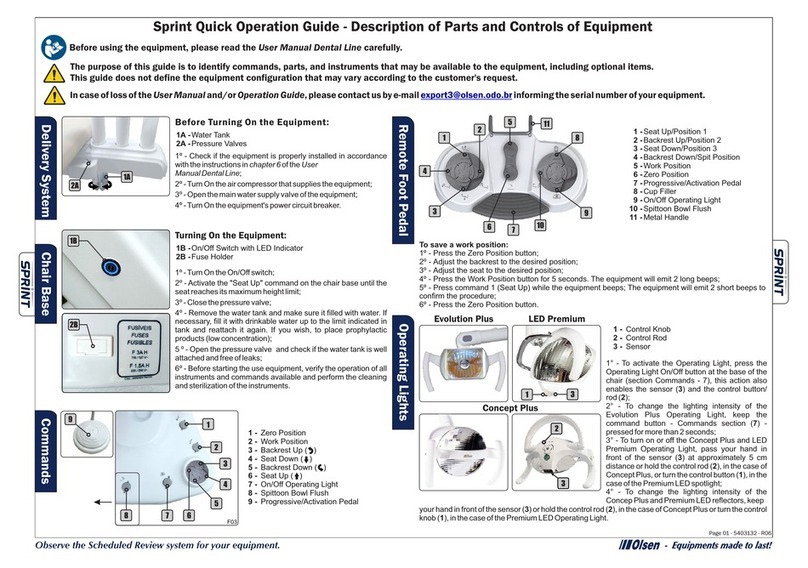

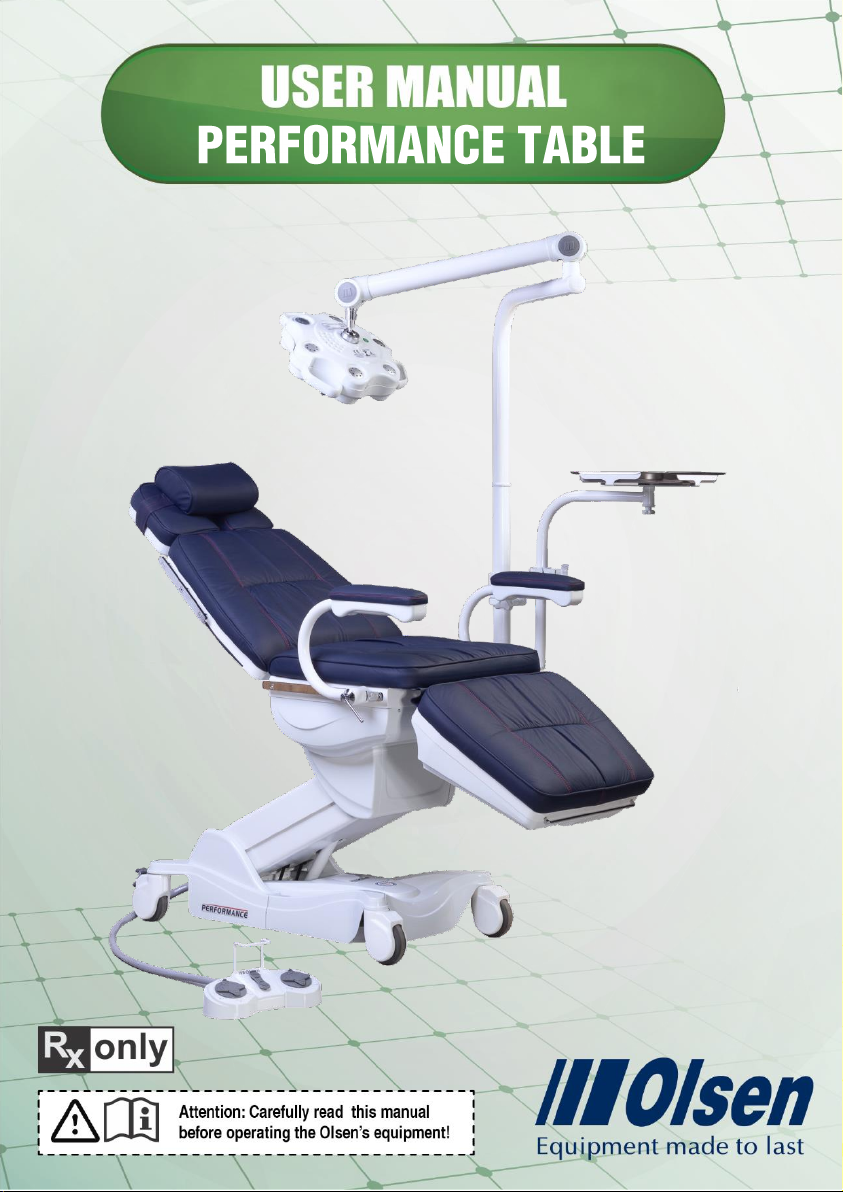

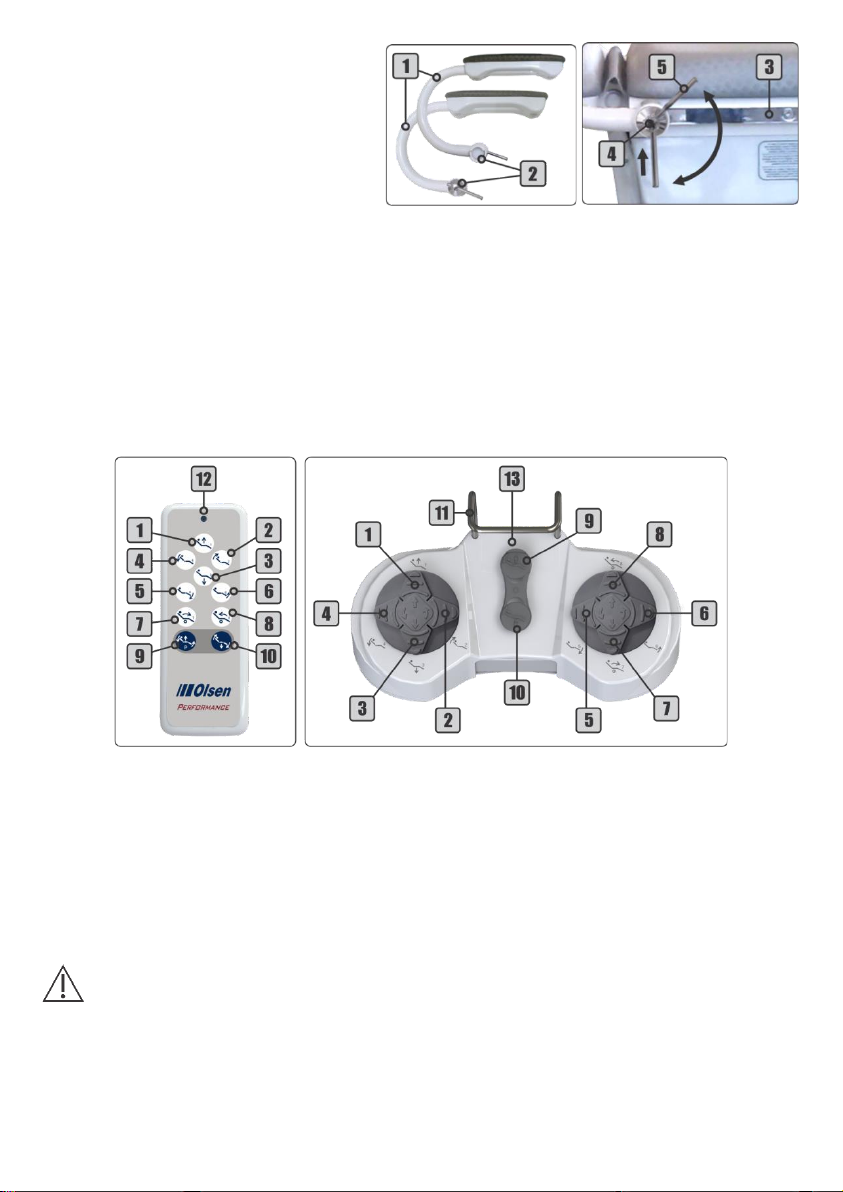

5.4.1 - Zero Position and Disembarkation Position

Used for loading and unloading of the patient, the Zero Position command has 2

positioning stages, Disembarkation Position and Zero Position, that make the equipment

automatically adjust the seat, backrest and legrest.

To activate the Disembarkation Position:

press the button once. Considering initially

the table in stretcher position, the backrest will rise up to 60º (relative to the floor) and the seat will lower

simultaneously. Then the footrest will lower by the end of your course.

To activate the Zero Position:

press the button again. The backrest will rise to its highest position. Note

that to activate the Zero Position you will need to finish moving the Disembarkation Position.

This command is also used to start and stop recording work positions. Whenever this command is

activated the equipment will emit 2 short beeps.

Note: at the end of each treatment activate the second stage of the Zero Position.

5.4.2 - Work Position

The Performance Table may perform from 6 to 8 automatic working positions with

simultaneous movement of backrest, seat, leg rest and seat tilt, optimizing the patient

positioning for procedures start.

To save a work position:

1º - Press the Zero Position button;

2º - Adjust the equipment on the desired position;

3º - Press the Work Position button for 5 seconds. The equipment will emit a long beep;

4º - Press command 1 (Seat Up) while the equipment beeps; The equipment will emit 2 short beeps to confirm

the procedure;

5º - Press the Zero Position button.

By pressing the Zero Position button, the work position 1 will be recorded. Repeat the above steps by

replacing in step 4, command 1 by any command of the other available numbers.

If the equipment has 4 motors, the command 8 is preset at the factory, setting the equipment on a

stretcher position. This command is not available for recording.

Note: the time to set up a work position is approximately 3 seconds, between the steps 3 and 4, when you hear a

long beep (step 3) then press one of the available commands to record the working position. If neither of the

commands is pressed during this period, the equipment will emit the second long beep, ending the process

followed by 3 short beeps indicating that the operation has been canceled.

When you press the Work Position button to set up a work position, do not hold it down after hearing

the first long beep, since this action will cancel the procedure.

To perform a work position:

1º - Press the Work Position button;

2º - Press the button for the requested work position; the equipment will position the backrest, seat and leg rest

according to the position previously recorded.

The time to call the position is 3 seconds. If within this period none of the commands buttons are

pressed, the equipment cancels the operation and delivers 3 short beeps in sequence.

5.4.3 - Stretcher Position

The command 8 also enables the stretcher position, where the equipment will lower the backrest up

to 180 ° to the seat and the footrest will be raised to its higher position.

To activate the stretcher position: press the Work Position command and then command 8 on the

remote foot pedal.

5.4.4 - Movements Interruption

All the equipment’s automatic commands may be interrupted during their execution with a simple

touch of any of the chair’s movement commands. For example, when calling a work position or performing

the Zero Position command, when pressing one of the chair commands, the movement will stop.

When you cancel an automatic movement, the equipment emits 3 short beeps.