3

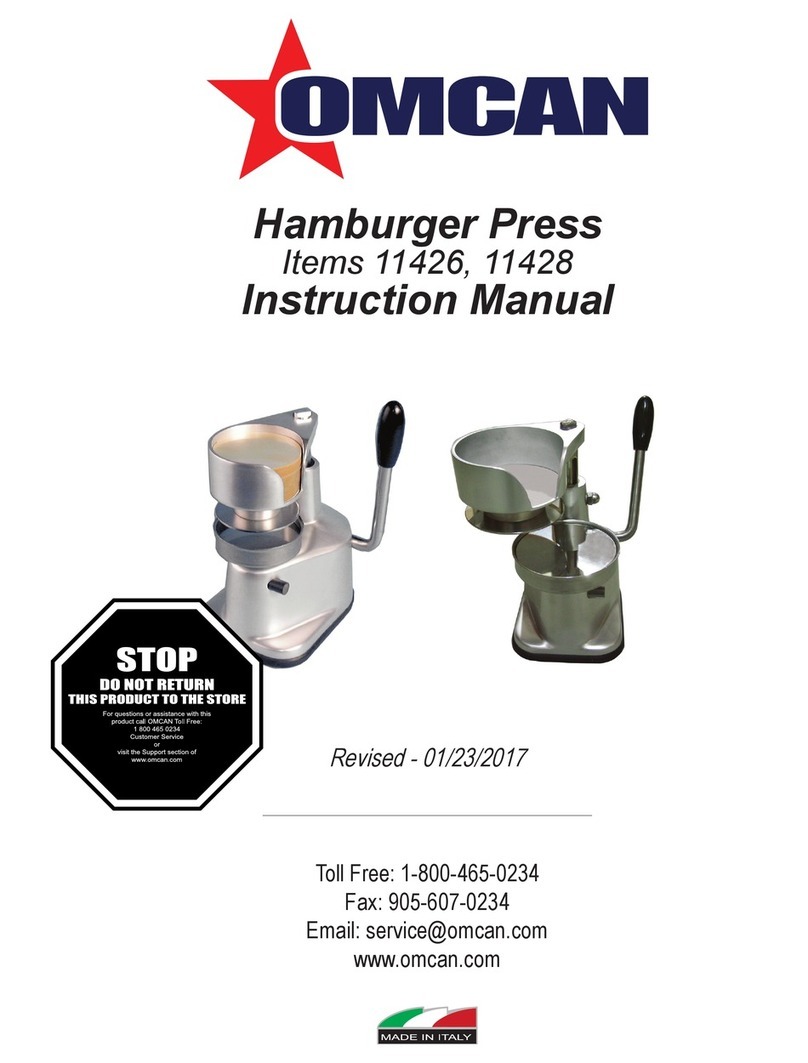

General Information

Safety & Warranty

Omcan Manufacturing And Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

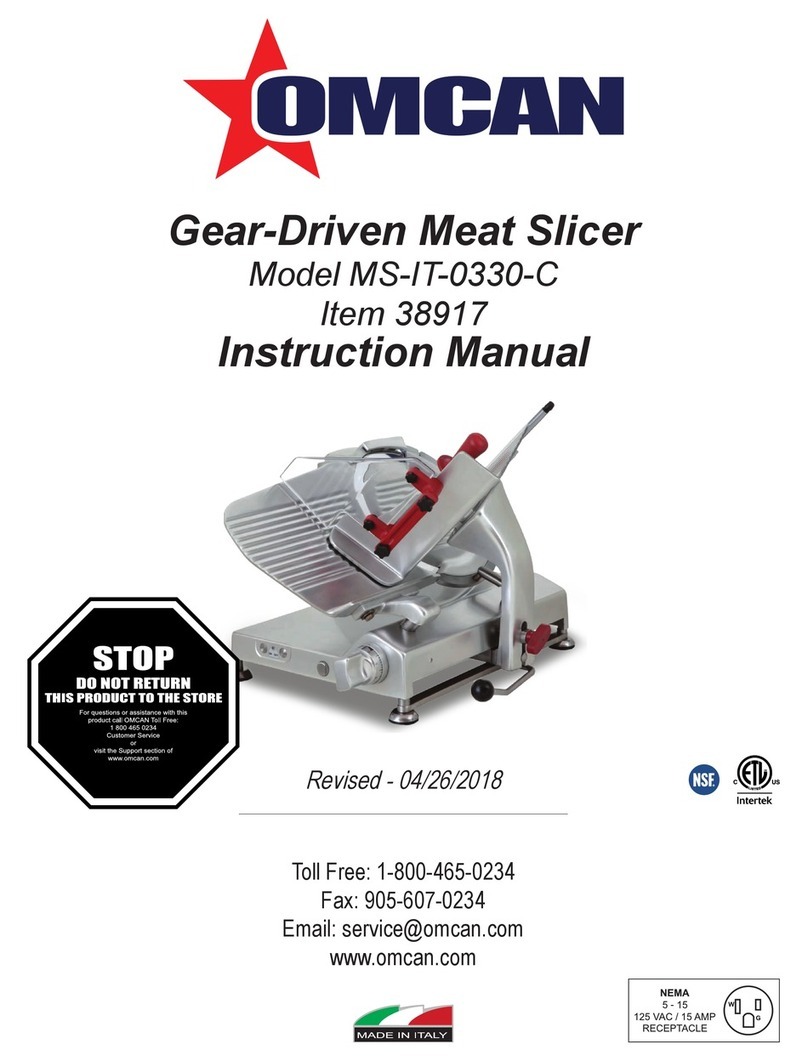

This manual contains all the necessary information to install, use and service the gravity slicers for food

(please see models in paragraph “Technical Description”). The scope of this document, hereinafter the

“manual”, is to permit users, and especially end users, to take all the cautions and provisions possible for using

this machine safely and for a long time.

LIMITS OF USE – SAFETY NORMS

These machine were designed and built to slice foodstuff in compliance to the norms of the CE 2006/95/EEC,

93/68/EEC, 2006/42/EEC, 2002/72/EEC, 2004/108 CE, REG 1935/2004/EEC, 2002/95/CE (RoHS) and to the

following regulations EN1974, EN ISO12100-1, EN ISO12100-2, EN 294, EN60204-1, EN60335-1, EN60335-

2-64.

GENERAL SAFETY REGULATIONS

The slicers must be used only by suitably trained personnel. Furthermore, this personnel must have read this

manual carefully. In particular, please comply to the following instructions:

• Install the machine according to the instructions contained in the “Installation” section;

• Do not remove the transparent protections, do not modify nor exclude the mechanical and electrical safety

devices;

• Do not use the machine with improvised connections, or provisional or non insulated cables;

• Check the power cable and gland plate on the machine body regularly and when necessary have them

replacedbyqualiedpersonnel;

• In case of anomalies, defective operation, incorrect movement, unusual noise, etc stop the machine

immediately;

• Before cleaning or servicing, disconnect the machine from the mains;

• Always use scratch-proof and non-slip gloves during cleaning or maintenance;

• Lay or remove the goods to be sliced on the sliding plate only when the latter is completely pushed back

and the thickness control knob positioned to 0;

• To move the carriage tray when slicing, use the handle or the product grip handle;

• For extraordinary maintenance (to replace the sharpener wheels, the blade, or others) please contact the

manufacturerorqualiedanddulyauthorizedpersonnel;