3 | Page

Table of Contents

1Notes, Warnings, and Cautions .................................................................................................................. 5

2Introduction .............................................................................................................................................. 6

3Hardware Setup ........................................................................................................................................ 7

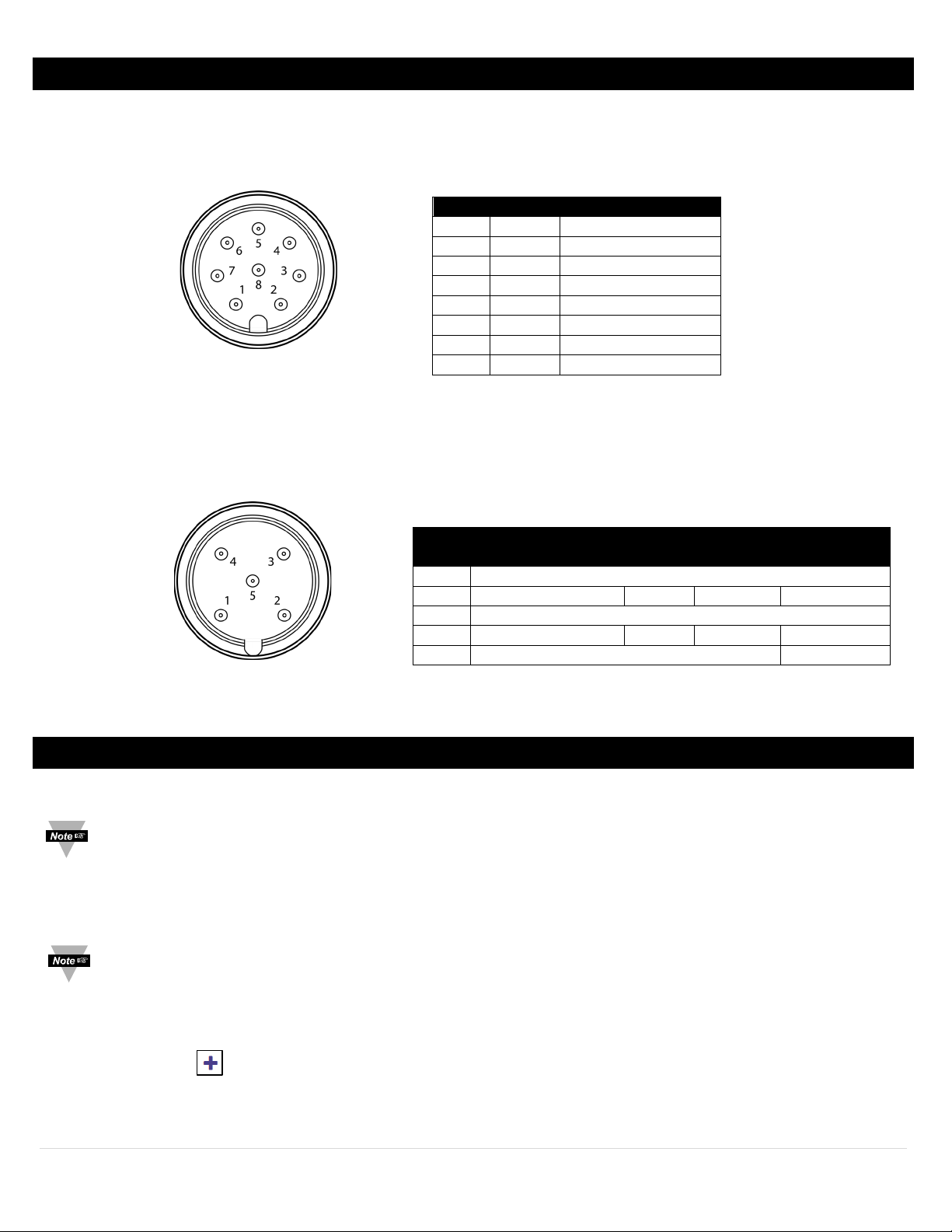

3.1 Connecting your Layer N Smart Interface ..........................................................................................................7

3.2 Digital Input Wiring Diagram ............................................................................................................................7

4SYNC Configuration ................................................................................................................................... 7

4.1 Connecting to SYNC - Automatic Detect ............................................................................................................7

4.2 Connecting to SYNC – Manual...........................................................................................................................7

4.2.1 Communication Interface..................................................................................................................................... 8

4.3 Digital Inputs Interface .....................................................................................................................................9

4.4 Configurable Digital I/O..................................................................................................................................11

4.4.1 Input Settings ..................................................................................................................................................... 11

4.4.2 Output Settings .................................................................................................................................................. 11

4.4.2.1 ON/OFF Functions........................................................................................................................................................... 12

4.4.2.2 Pulse-Width Modulation (PWM) .................................................................................................................................... 12

4.4.3 Setting Alarms .................................................................................................................................................... 12

4.5 ON/OFF Control .............................................................................................................................................13

5Appendix: SP-013 Registers...................................................................................................................... 14

5.1 Digital Descriptor ...........................................................................................................................................14

5.1.1 Digital Measurement Types ............................................................................................................................... 14

5.1.2 Digital Data Type/Format................................................................................................................................... 15

5.1.2.1 Data Type ........................................................................................................................................................................ 15

5.1.2.2 Factory Calibrate............................................................................................................................................................. 15

5.1.2.3 Sensor Writeable ............................................................................................................................................................ 15

5.1.2.4 Smart Sensor................................................................................................................................................................... 15

5.1.3 Digital Configuration .......................................................................................................................................... 15

5.1.3.1 Sensor Range / Type ....................................................................................................................................................... 15

5.1.3.2 Lock ................................................................................................................................................................................. 15

5.1.3.3 Apply Scaling ................................................................................................................................................................... 15

5.1.3.4 Assigned .......................................................................................................................................................................... 16

5.1.3.5 Available.......................................................................................................................................................................... 16

5.1.4 Digital I/O Byte ................................................................................................................................................... 16

5.1.5 IPSO Digital Input Sensor Definition................................................................................................................... 16

5.1.5.1 Sensor Trigger Function .................................................................................................................................................. 17

5.2 Digital Input / Output Descriptor ....................................................................................................................17

5.2.1 DIO Sensor Type ................................................................................................................................................. 17

5.2.2 DIO Data Type/Format ....................................................................................................................................... 17

5.2.2.1 Data Type ........................................................................................................................................................................ 17

5.2.2.2 Factory Calibrate............................................................................................................................................................. 17

5.2.2.3 Sensor Writeable ............................................................................................................................................................ 18

5.2.2.4 Smart Sensor................................................................................................................................................................... 18

5.2.3 DIO Input Configuration ..................................................................................................................................... 18

5.2.3.1 Lock ................................................................................................................................................................................. 18

5.2.3.2 Apply Scaling ................................................................................................................................................................... 18

5.2.3.3 Assigned .......................................................................................................................................................................... 18

5.2.3.4 Available.......................................................................................................................................................................... 18

5.2.4 DIO Device Configuration................................................................................................................................... 18

5.2.4.1 Invert............................................................................................................................................................................... 18

5.2.4.2 Enable ............................................................................................................................................................................. 18