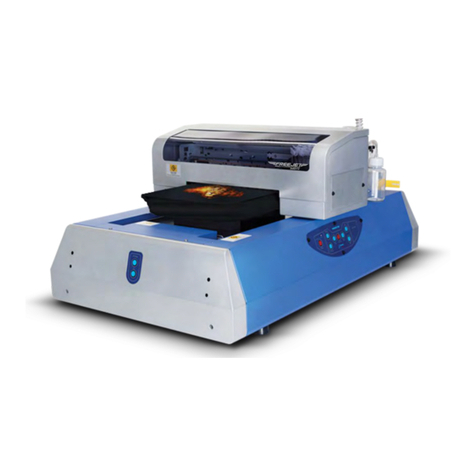

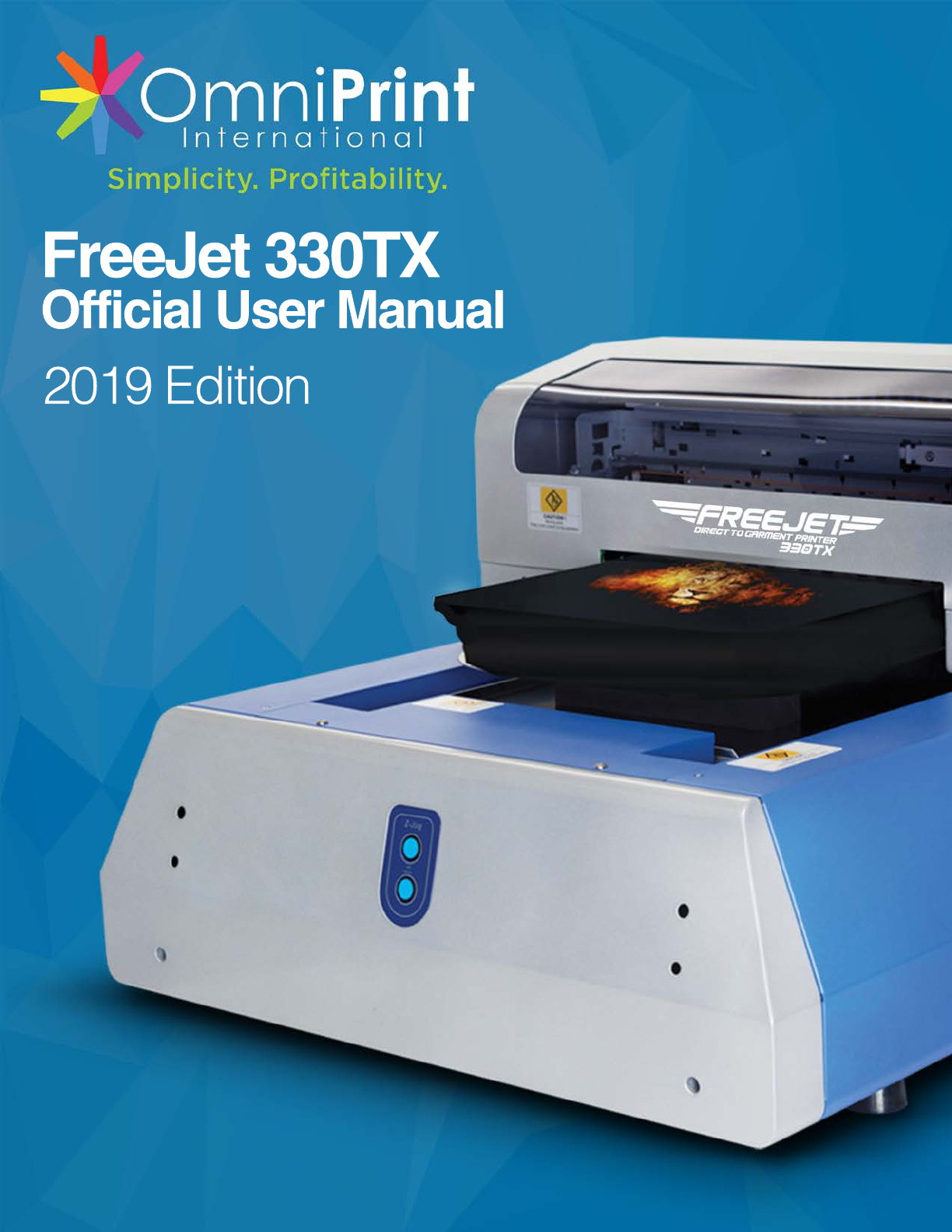

DTG Basics - An Introduction

Direct-to-Garment (DTG) Printing is a modern form of printing on garments, implementing a

digital inkjet printhead to produce vibrant images with impeccable detail on a wide range of

apparel. First introduced in 1994, DTG print technology has progressed to the worldwide phen-

omenon it has become today and it’s only getting started! OmniPrint’s critically acclaimed DTG

print technology has been recognized as one of the best in the industry for the last 3 years and

pride themselves in offering the best quality prints at the lowest production costs.

Like any machine ever, there will be a learning curve to mastering how to operate your printer.

The most important elements of a good DTG print depend on the quality of the garment as well

as the pretreatment application. Because of this, you will need to ensure that for every print, you

are choosing the right garment and properly pretreating the garment. A common misconception

is that bad prints result from the printer when in reality, the bad prints stem from a pretreatment

error or a bad garment all-around.

Choosing The Right Garment

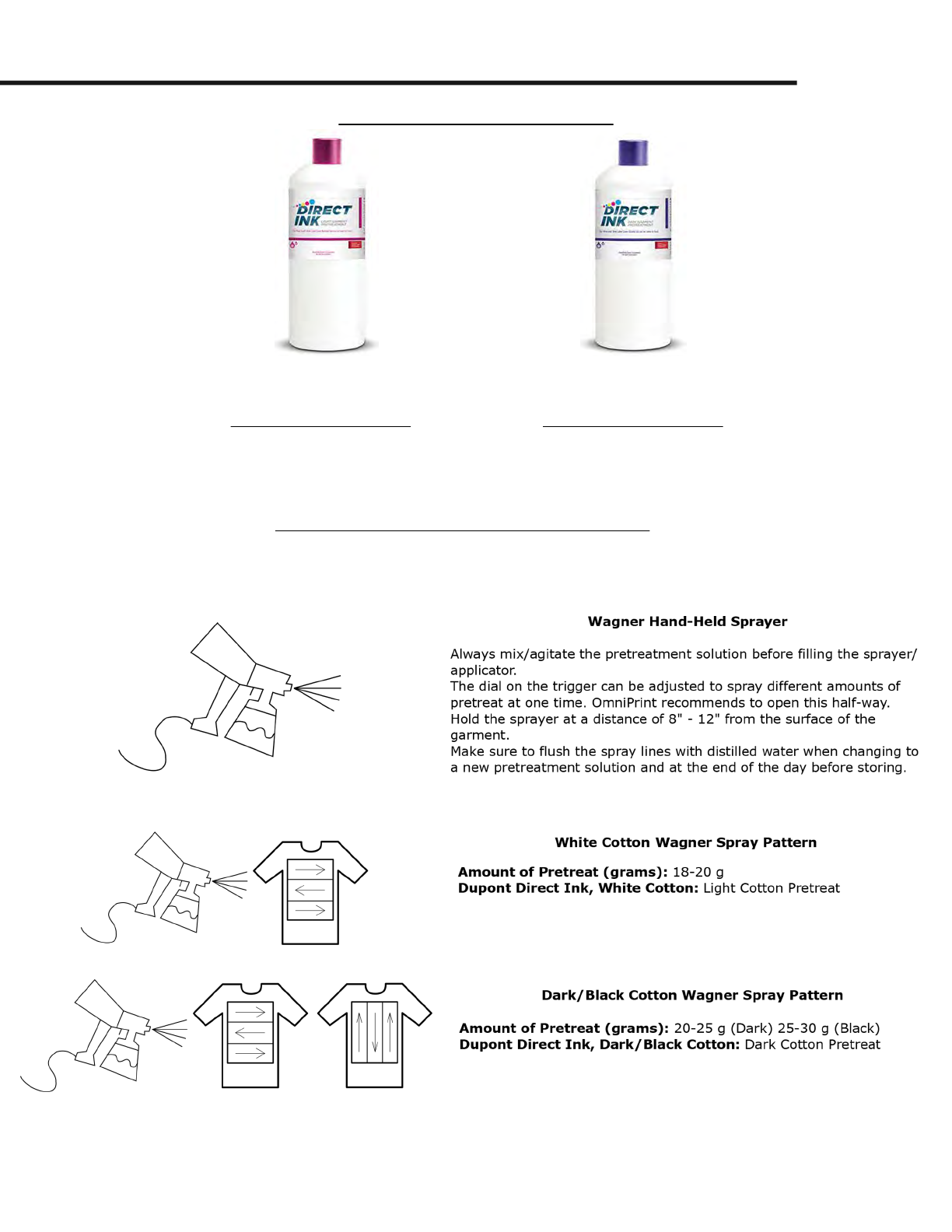

Properly Pretreating The Garment

Choosing your garment will be the first most important aspect of DTG printing. Garments that

are too thin or that are coated with anti-stain guards, moisture wicking, etc will negatively affect

the overall quality of your print. The most important thing to keep in mind for this is that not all

garments will absorb the pretreatment and inks the same way. Your best bet is to choose a high

quality, tightly weaved (ringspun, combed ringspun, etc) garment that was pre-shrunk (if appli-

cable). Not choosing the right garment will result in color drop-outs, quality loss, and sometimes

even staining if the shirt’s dye was low quality.

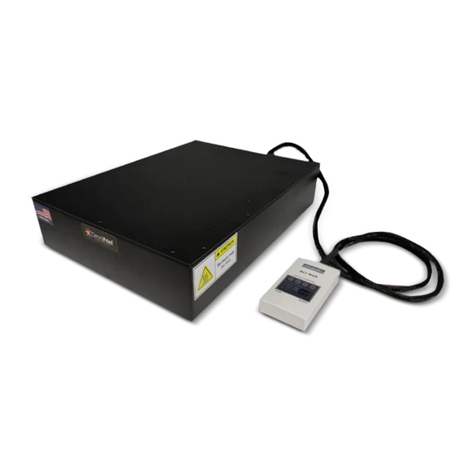

Pretreatment assists with two important roles in the printing process. First as an adhesive layer

similar to primer and second as a chemical agent that flashes the white ink to be able to print the

color layer on top without the two layers mixing and ruining the print. If the garment is not pre-

treated properly, there will be insufficient amounts of pretreat to successfully achieve the adh-

esive or flashing properties required to achieve a good print.

As an operator in your beginner stages, you will run into some challenges along the way but

worry not, these are normal and will assist you in learning the operation of your printer. If at any

point you need assistance, it’s okay! We are here to help! Take advantage of your active warranty

and contact tech support whenever you run into something you need assistance with something

that cannot be resolved with the user manual or tutorial videos.

Take advantage of your active warranty! Contact Tech Support:

1-855-373-3538

option

2

•

email

[email protected] •

open

a

ticket

at

omniprintonline.com/support