5

3-3 Connecting the Power Adapter

This printer requires an external power supply. Be sure to use a power supply that

matches the specifications.

1. Make sure the power switch is OFF.

2. Insert the output plug of the power adapter into the DC jack of the printer.

3. Plug the adapter or the power supply’s cord into an outlet.

4. For best results use one of the following Omniprint adapters:

OMPS190-915-NA (120VAC input)

OMPS190-915-EU (220-240VAC input)

OMPS190-915-SMPS (90-240VAC input)

Output: 9VDC 1.5A, 2.1mm x 5.5mm female plug, Center positive

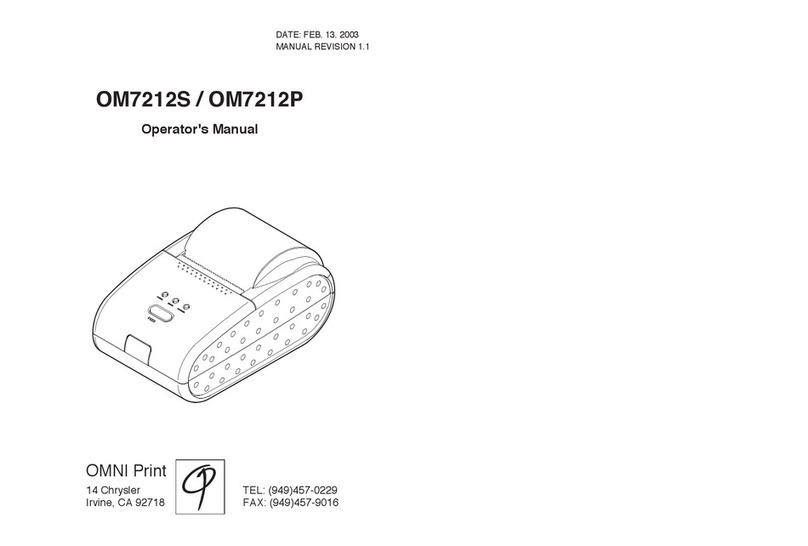

3-4 Connecting the Interface Cable

You need an appropriate serial interface or parallel interface cable to connect your

computer to the printer.

3-4-1 Serial Interface Cable: OM19X-S

1. Make sure that both the printer and computer are turned off.

2. The serial printer comes with a DB-25 female connector. Plug the DB-25 male

end of the cable into the printer connector, as shown above.

3. Use a screw driver to fasten the cable screws to the two nut screws installed on

the printer connector.

4. Connect the other end, DB9-F connector, to your computer.

5. Use Omniprint part number:

CBL-625F-25M (DB-25 male on the host side)

CBL-69F-25M (DB-9 male on the host side)