8

CHAPTER I. SITE PREPARATION GUIDELINES

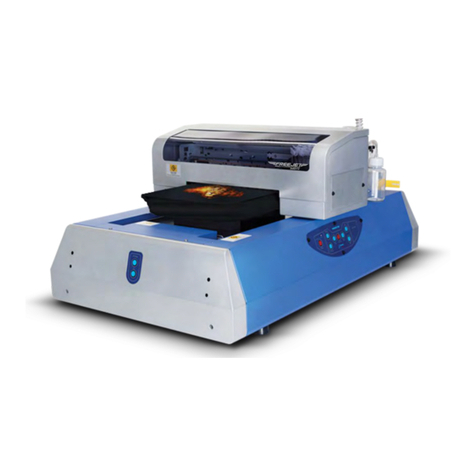

To prepare for the installation of your FreeJetTX Direct-To-Garment printer please respond to

the following information:

1. FreeJet Electrical Requirements: 110V, 25watt, 1 phase, 50/60 Hz. The FreeJET

should have a dedicated outlet/electrical supply for the Freejet. Do NOT plug other high

power use items such as an air conditioning unit, heat press, etc. into the same circuit.

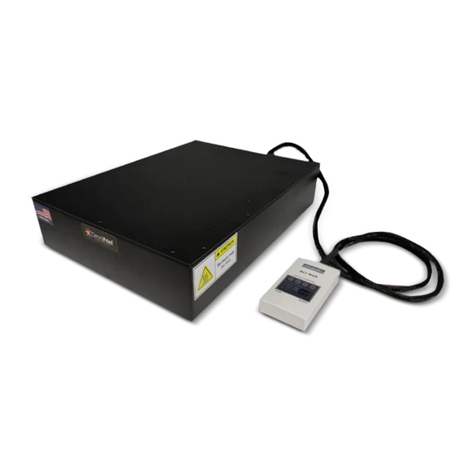

To protect the warranty, the Freejet printer must be protected from electrical surges. A

‘UPS’ (uninterruptable power supply) with battery back-up is highly recommended. In

the event of a power failure, this will allow you to perform a complete turn off procedure,

allowing the print head to safely return to its capping position. At a minimum, use a

power strip with surge protection.

2. Host Computer: You will need to supply a computer to run the unit and house the

Omniprint Direct Rip software. The computer (or laptop) should have Windows O.S. with

XP or Vista, 2 GB ram, dual core processer, with at least 4 USB ports. Adobe

Photoshop is highly recommended as complementary graphics software.

3. Room Environment: The FreeJet TX should not be exposed to direct sunlight, direct

airflow, dusty areas, strong magnetic forces or excessively high humidity. The machine

does not like to be too dry or too moist with a level of 40% to 80% relative humidity being

ideal. For dry months, it may be necessary to humidify the room. Ultrasonic humidifiers

can be purchased for a reasonable price at your local home repair store. Since you will

be handling wet ink to refill the Bulk System ink bottles, you should also protect any

carpet or floor covering with mats.

Like any Hi-Tech electronic device, your inkjet printer does NOT like being in a hot or

cold shop or a garage without proper air-conditioning controls. If left unattended for

several days or weeks in a hot dry environment, the print head will clog. To prevent

clogging place the print head on the exclusive FreeJet TX head capping unit when not in

use. If your FreeJet TX is not going to be used for more than a week at a time it will be

necessary to drain the ink lines.

At night, and when the printer is not in use, cover the machine to protect it from airborne

dust and debris.

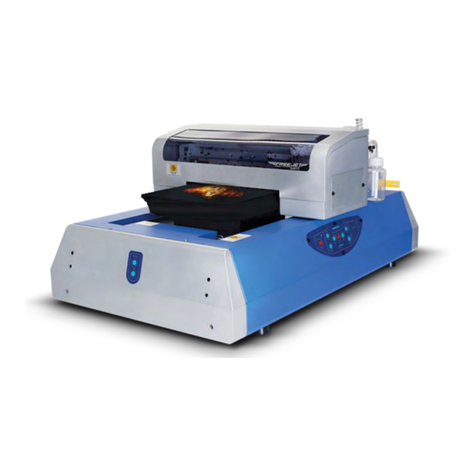

4. Working Space: The FreeJet dimensions are 42”l x 25”w 18”h.

a. The recommended dedicated working space for the FreeJet is 6’x6’. The

FreeJet needs to be placed on a sturdy table or platform that can withhold 200

lbs and incorporate the entire footprint of the printer, 42”l x 25”w. No part of the

FreeJet should overhang the table or platform. A comfortable working height is

30”.

b. When using White ink, you must apply a Pre-treatment to the garments before

printing. DO NOT spray this Pretreatment near your FreeJet TX. We suggest

you pre-treat garments in a separate area, if possible but at a minimum, make an

enclosure around the pretreatment area to limit the amount of overspray in the

area. The Pretreatment is sticky and can damage the Print Head as well as the

Encoder Strip.

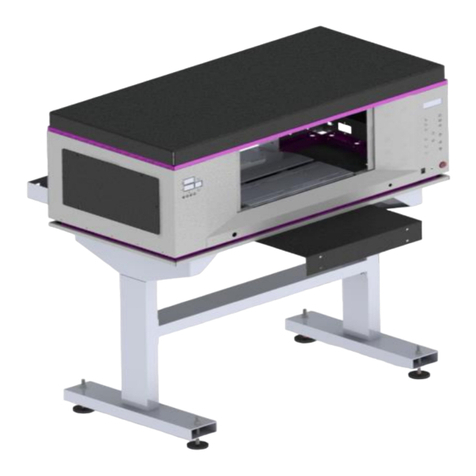

5. Pre-Treat: It is necessary to pre-treat any garments that will be printed with white ink.

There are 2 options. An automatic pre-treat machine or a hand held spray gun device.