A-135E3M-V

E3M-V

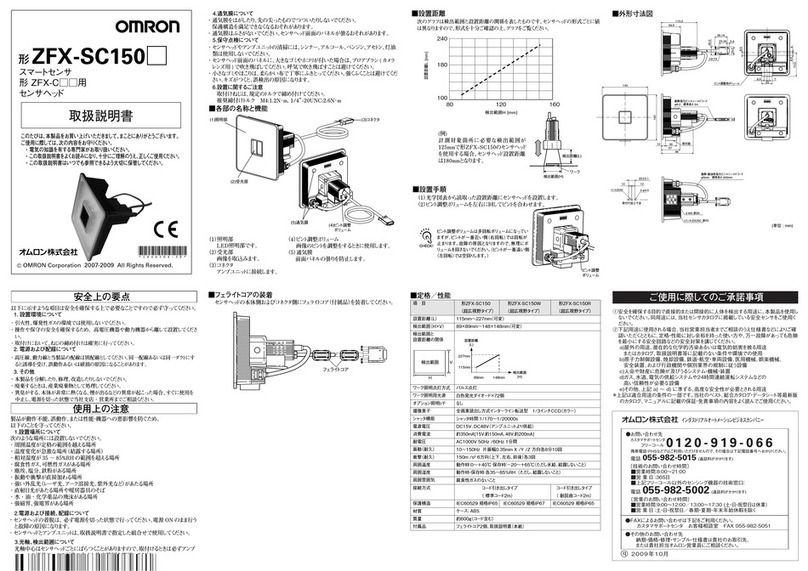

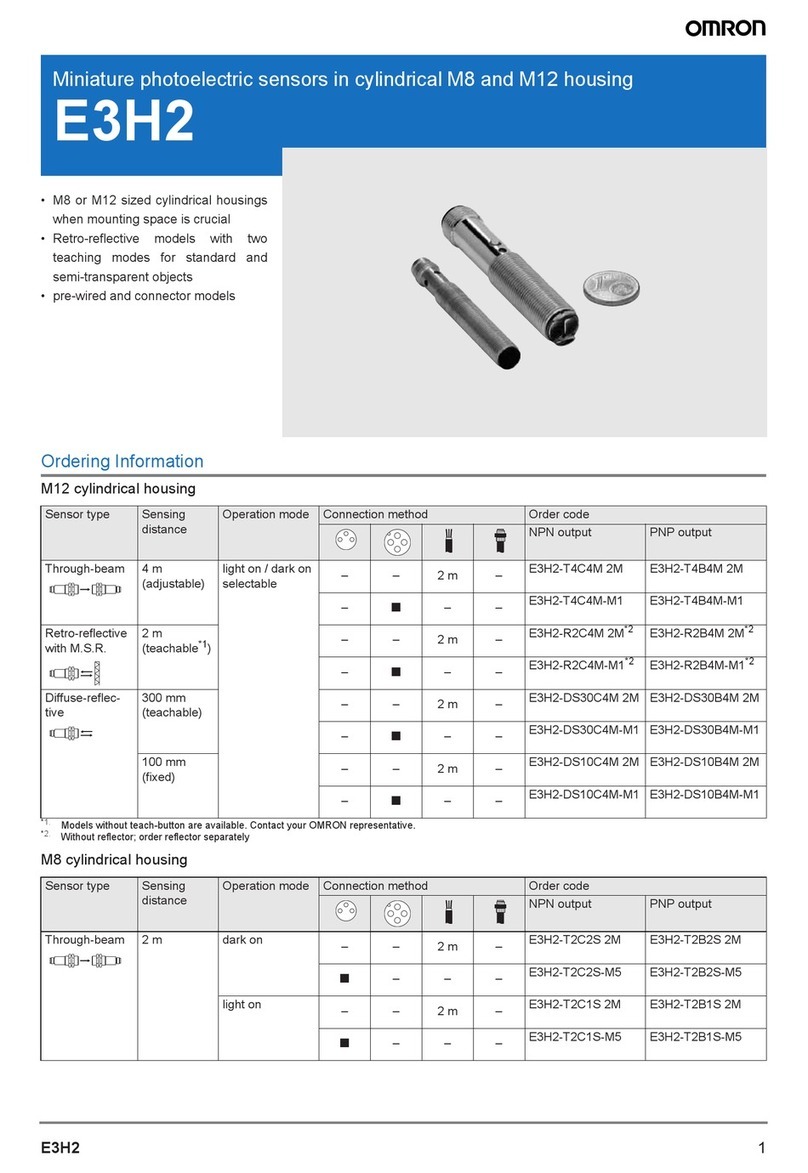

Specifications

Ratings/Characteristics

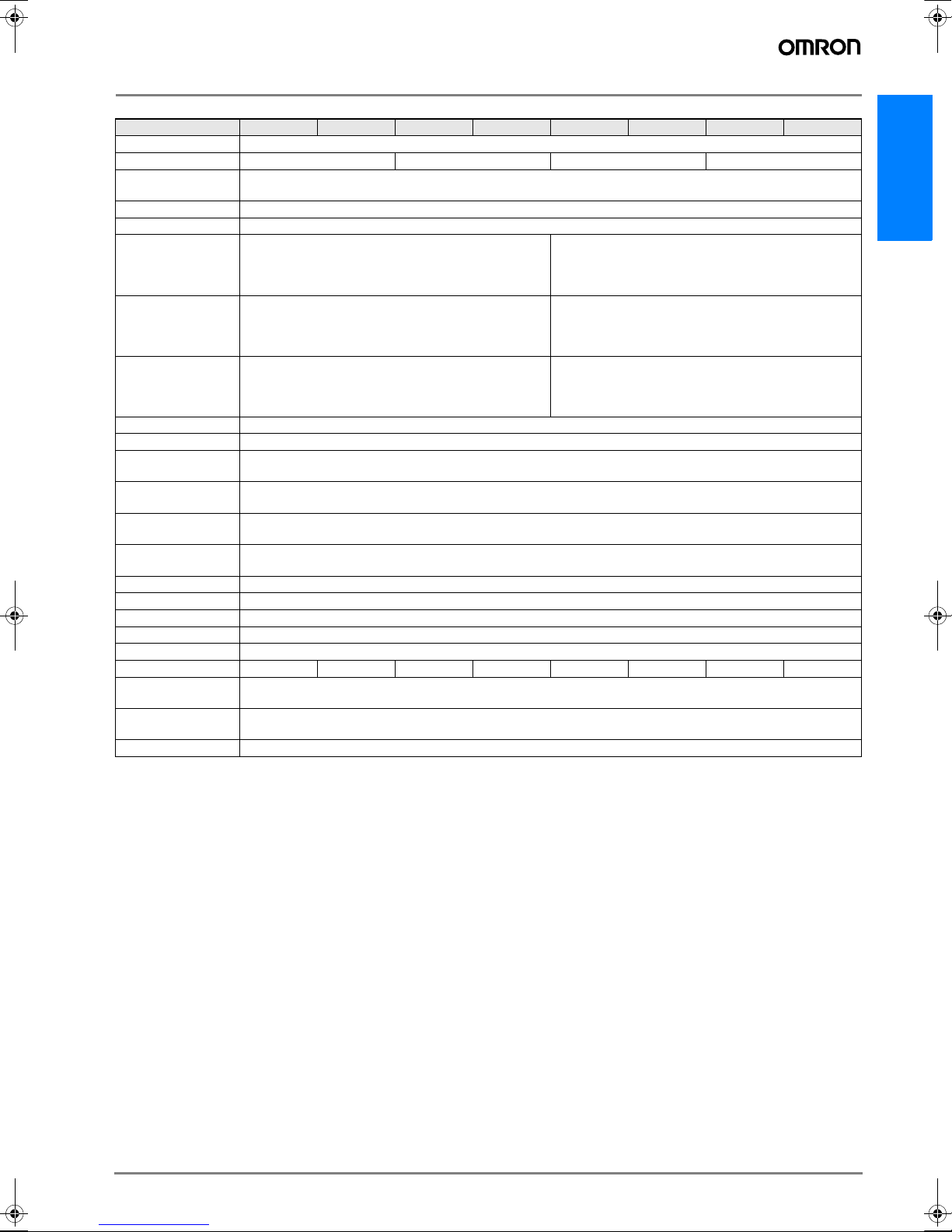

Item E3M-VG11 E3M-VG12 E3M-VG21 E3M-VG22 E3M-VG16 E3M-VG17 E3M-VG26 E3M-VG27

Sensing distance 10±3 mm

Spot size (W x H) 1 x 4 mm 4 x 1 mm 1 x 4 mm 4 x 1 mm

Light source (wave-

length) Green LED (525 nm)

Power supply voltage 10 to 30 VDC, ripple (p-p) 10% max.

Current consumption 100 mA max.

Control output

Load power supply voltage: 30 VDC max.

Load current: 100 mA max.

(Residual voltage: 1.2 V max.)

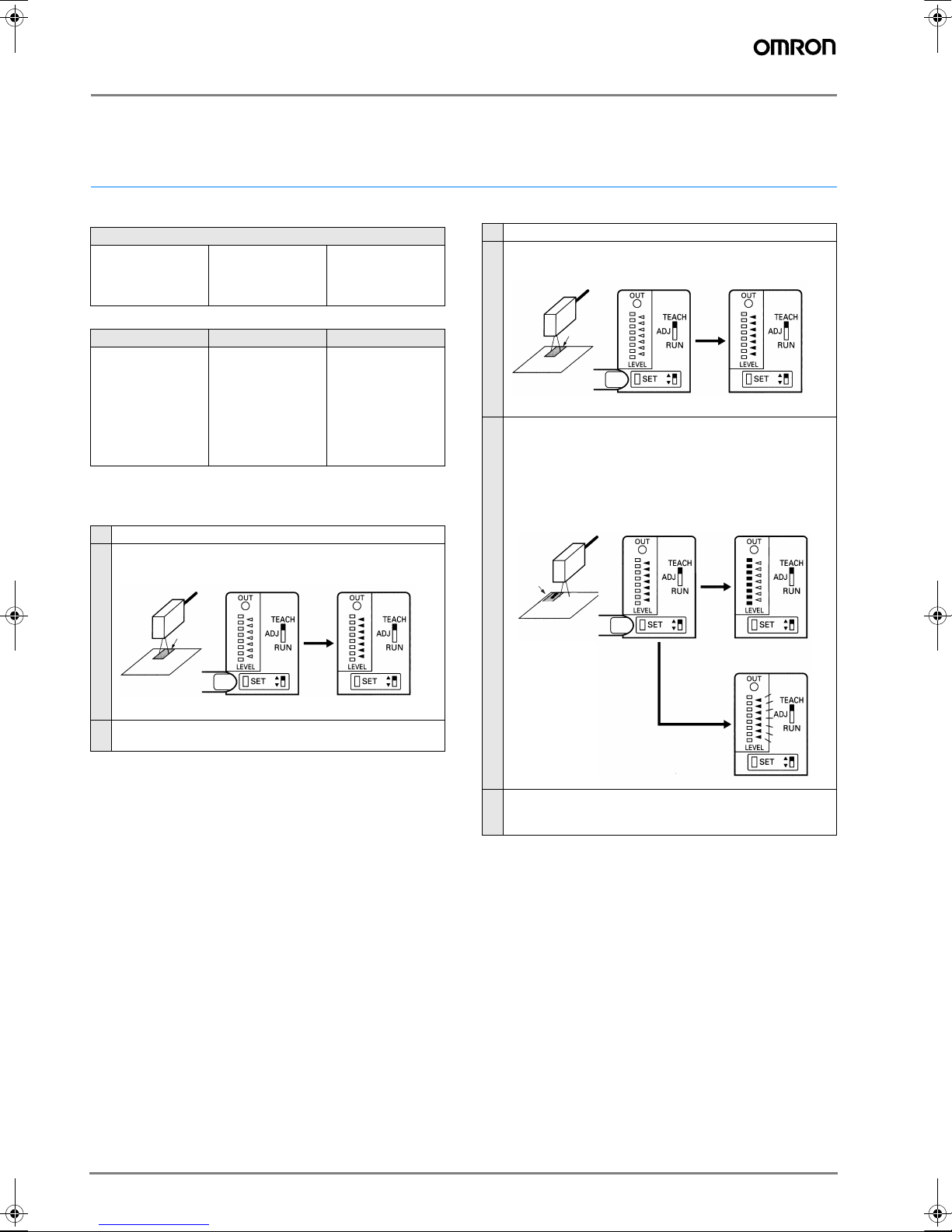

NPN open collector output type

Load power supply voltage: 30 VDC max.

Load current: 100 ma max.

(Residual voltage: 2 V max.)

PNP open collector output type

Remote control input1

1. Remote controll input and answer-back output share the same signal line.

ON: Short-circuited to 0 or 1.5 V max.

(with a flow current of 1 mA max.)

OFF: Open or VCC - 1.5 V to VCC

(with a leakage current of 0.1 mA max.)

ON: VCC - 1.5 V to VCC

(with an absorption current of 3 mA max.)

OFF: Open or 1.5 V max.

(with a leakage of 0.1 mA max.)

Remote control

output1

Load power supply voltage: 30 VDC max.

Load current: 100 mA max.

(Residual voltage: 1.2 V max.)

NPN open collector output type

Load power supply voltage: 30 VDC max.

Load current: 100 ma max.

(Residual voltage: 2 V max.)

PNP open collector output type

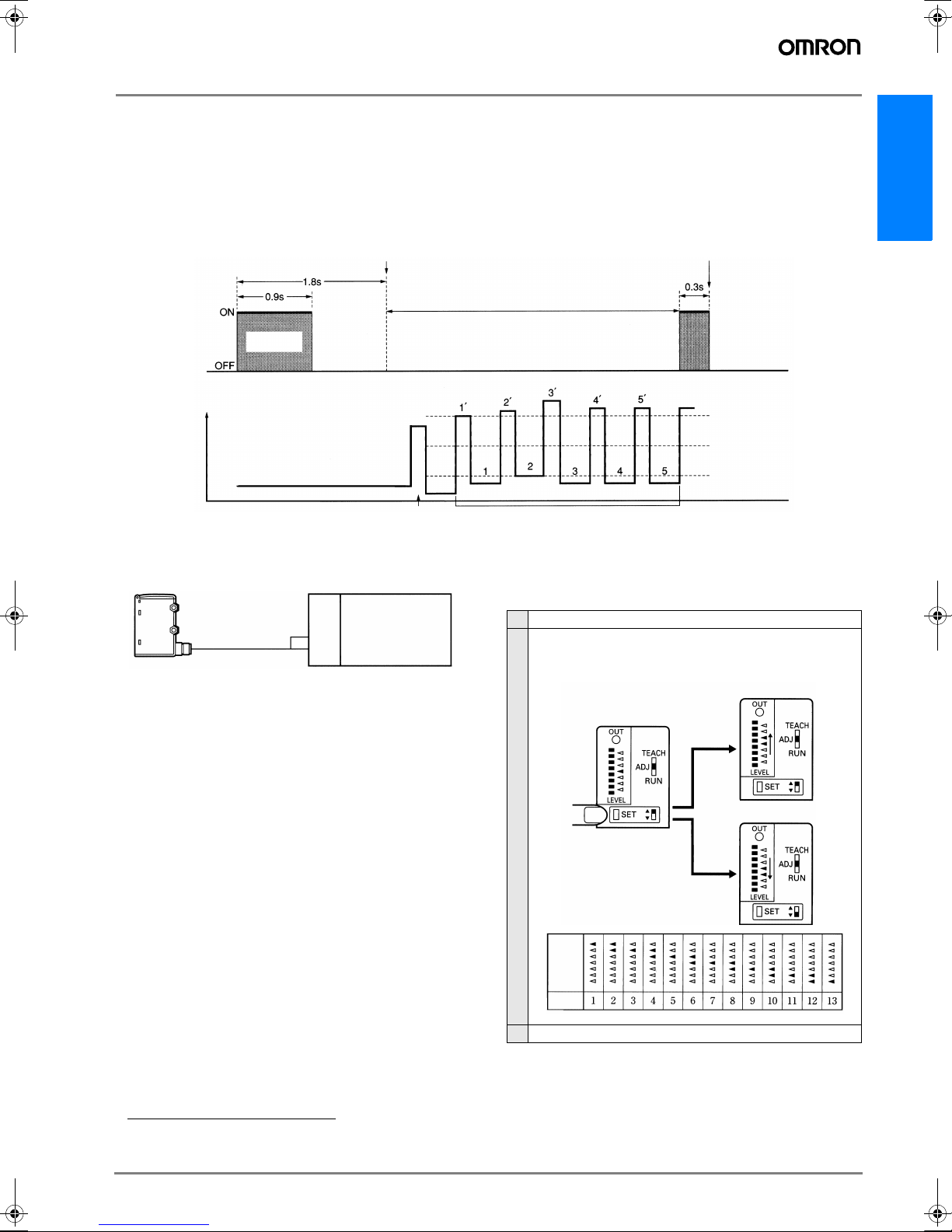

Bank selection Two banks selectable. Available for remote control only. (Refer to Remote Control Function.)

Circuit protection Protection from reversed power supply connection and load short-circuit

Response time ON: 50 µs max.

OFF: 70 µs max.

Ambient illumination

(on receiver lens)

Incandescent lamp: 3,000 lx max.

Sunlight: 10,000 lx max.

Ambient temperature Operating: -20°C to 55°C/Storage: -30°C to 70°C

(with no icing)

Ambient humidity Operating: 35% to 85%/Storage: 35% to 95°C

(with no condensation)

Insulation resistance 20 M min. (at 500 VDC)

Dielectric strength 1,000 VAC, 50/60Hz, 1 min.

Vibration resistance2

2. The Sensor withstands 0.75 mm double amplitude or 100 m/s² if the mounting bracket is attached to the sensor

Destruction: 10 to 55 Hz, 1-mm double amplitude or 150 m/s2 for 2 hrs each in X, Y, and Z directions

Shock resistance3

3. The Sensor withstands 300 m/s² if the mounting bracket is attached to the sensor.

Destruction: 500 m/s2 3 times each in X, Y, and Z directions

Degree of protection IEC60529 IP67 (with protective cover)

Connection method Connector Pre-wired Connector Pre-wired Connector Pre-wired Connector Pre-wired

Weight with package

box Approx. 100 g

Material Case: Polybutylene terephthalate

Lens: Acrylic (PMMA)

Others Instruction manual

F502-EN2-04.book Seite 135 Dienstag, 26. Juli 2005 5:48 17