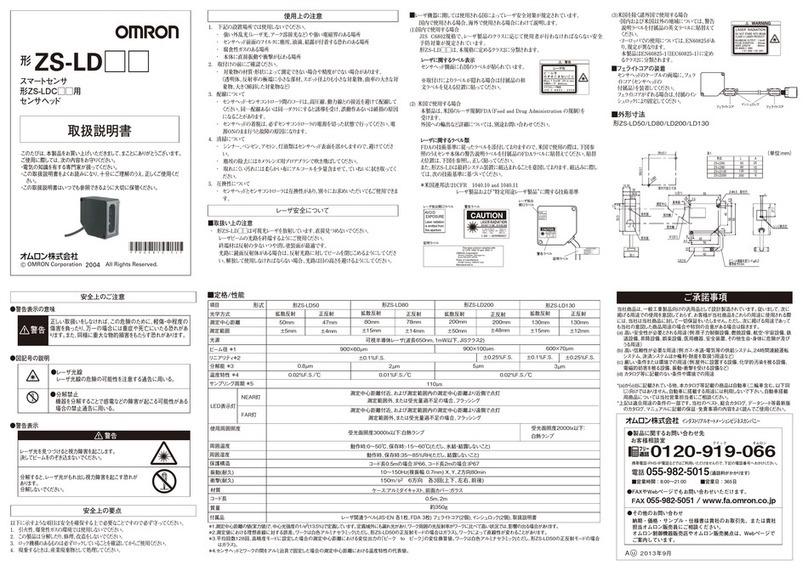

B-55Z510

Z510

Sensors: Z510-SW2T, Z510-SW6, and Z510-SW17

Note: 1. The minimum light intensity at the edges of the beam is defined as 1/e2(13.5%) of the intensity at the center of the beam. Some light will

scatter beyond this beam region and the measurement may be affected if the immediate vicinity around the workpiece is highly reflective.

2. This is the error with respect to the theoretical line of the displacement output when measuring the standard OMRON quartz glass. The

linearity may vary depending on the workpiece being used.

3. This is the error with respect to the theoretical line of the displacement output when measuring a standard OMRON stainless-steel block.

The linearity may vary depending on the workpiece being used.

4. This is the error with respect to the theoretical line of the displacement output when mea-

suring the standard OMRON white alumina ceramic. The linearity may vary depending on

the workpiece being used.

5. This is the displacement output’s peak-to-peak displacement conversion value. These fig-

ures are for measurement of the standard OMRON quartz glass (mirror reflection) or stan-

dard OMRON stainless-steel block (diffuse reflection) at the center of the measurement

region. The resolution performance characteristics may not be met when operating in a

magnetic field.

6. These figures are for Sensors connected to a Z510-WC10E or Z510-WC15E and averaged over 16 measurements. The averaged data

was transmitted to a PC through an RS-232C connection for storage and processing.

7. This is the displacement output’s peak-to-peak displacement conversion value. (These figures are for measurement of the standard OM-

RON white alumina ceramic at the center of the measurement region.)

The resolution performance characteristics may not be met when operating in a strong magnetic field.

8. These figures are for Sensors connected to a Z510-WC10E or Z510-WC15E and averaged over 64 measurements. The averaged data

was transmitted to a PC through an RS-232C connection for storage and calculations.

9. This is the value measured when the gap between the Sensor and workpiece (white alumina ceramic) is fixed with an aluminum jig.

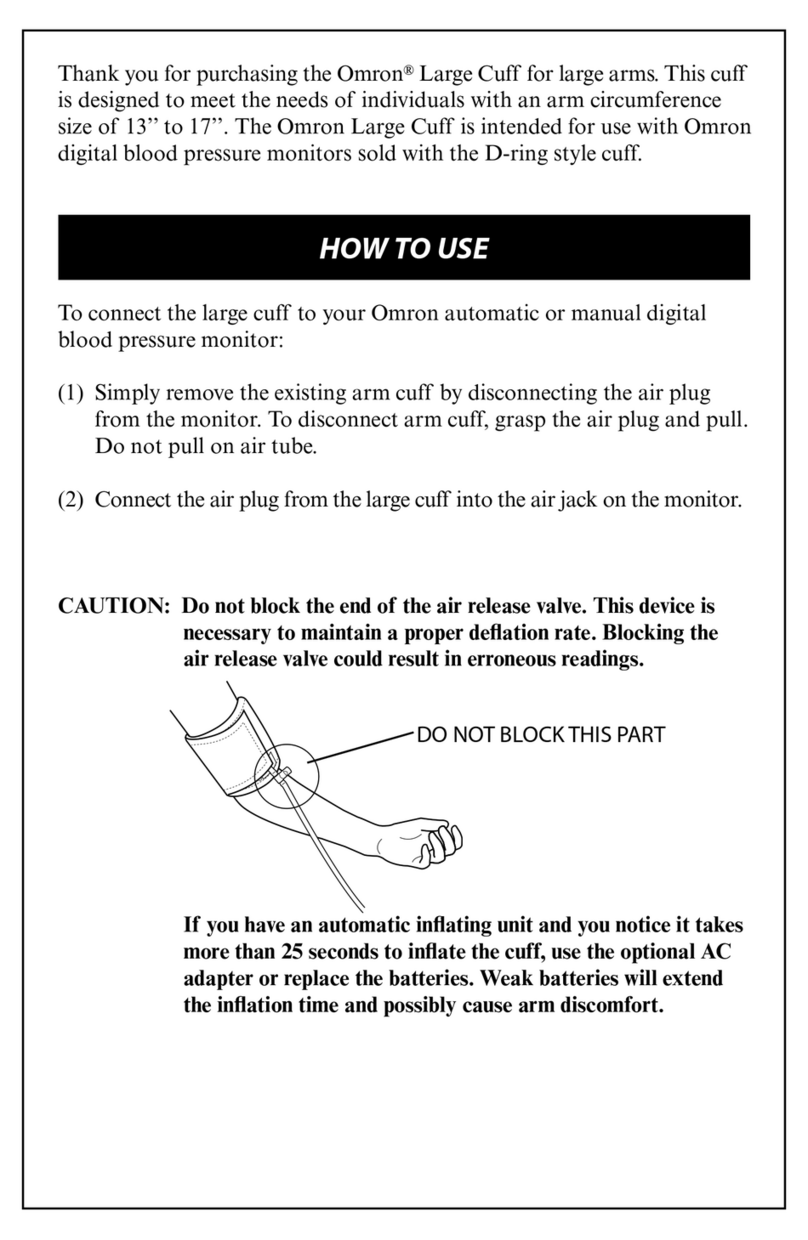

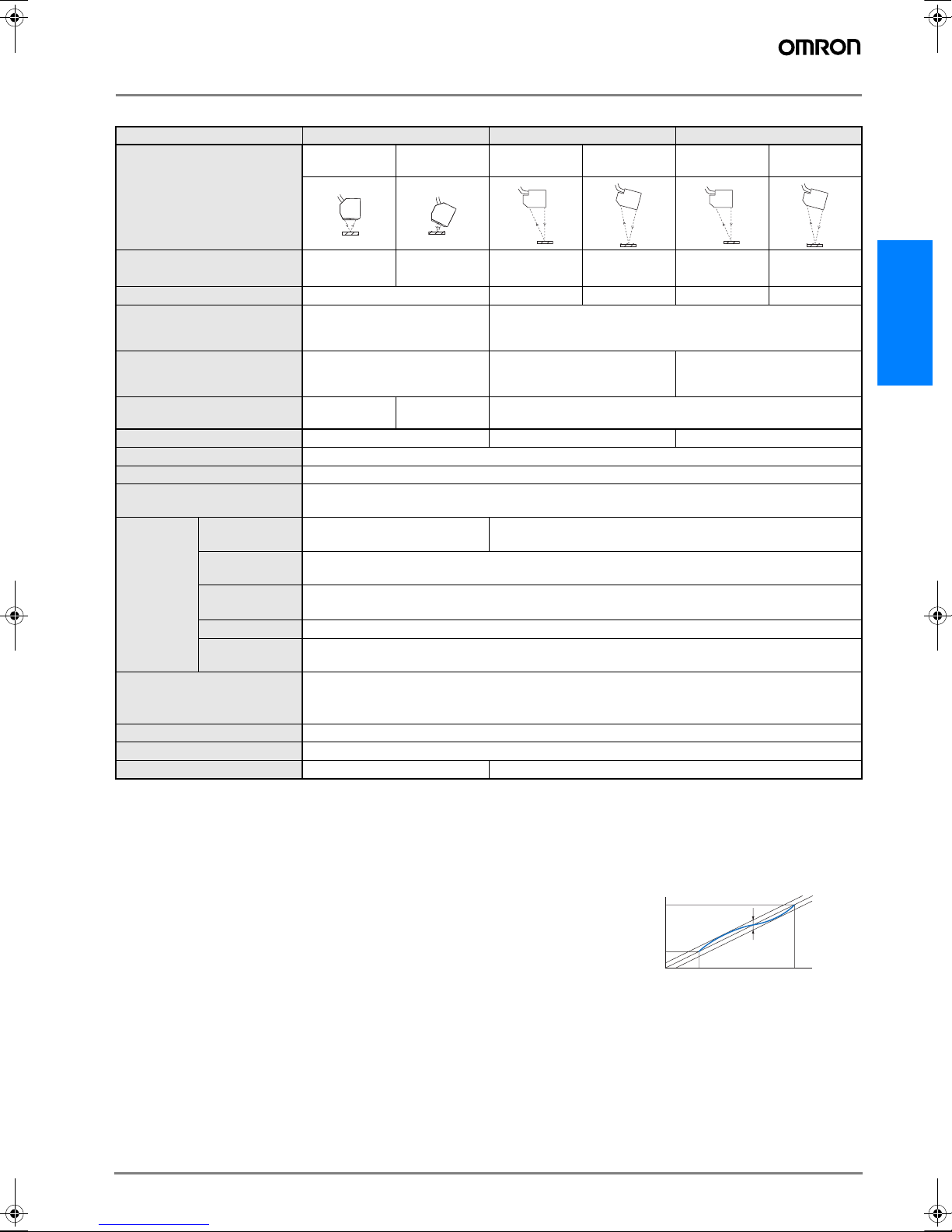

Sensor model Z510-SW2T Z510-SW6 Z510-SW17

Measurement mode

Mirror reflection Diffuse

reflection Diffuse

reflection Mirror reflection Diffuse

reflection Mirror reflection

Measurement distance at center 20 mm (16 mm with

beam cover mount-

ed)

5.2 mm 50 mm 44 mm 100 mm 94 mm

Measurement range ±0.8 mm ±5 mm ±4 mm ±20 mm ±16 mm

Light source Visible semiconductor laser

(Wavelength: 670 nm, 15 mW

max., class 3B)

Visible semiconductor laser

(Wavelength: 658 nm, 15 mW max., class 3B)

Beam dimensions (See note 1.) 20 µm ×4 mm typical at the ref-

erence distance

(2-mm measurement region)

30 µm ×24 mm typical at the ref-

erence distance

(6-mm measurement region)

60 µm ×45 mm typical at the ref-

erence distance

(17-mm measurement region)

Linearity ±0.1% F.S.

(See note 2.) ±0.1% F.S.

(See note 3.) ±0.1% F.S. (See note 4.)

Resolution 0.25 µm (See notes 5 and 6.) 0.3 µm (See notes 7 and 8.) 1 µm (See notes 7 and 8.)

Sampling period 9.94 ms

LED indicator (Laser indicator) Lit when the laser is ON.

Temperature characteristic

(See note 9.)

0.01% F.S./°C

Environmen-

tal resistance

Degree of protec-

tion

IP64 IP66

Ambient operat-

ing illumination

Illumination at light-receiver surface: 3,000 lx max. (incandescent light)

Ambient tempera-

ture

Operating: 0 to 50°C (with no icing or condensation)

Storage: -15 to 60°C (with no icing or condensation)

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Vibration (de-

struction)

10 to 150 Hz (double amplitude of 0.35 mm) for 8 minutes each in the X, Y, and Z directions

Materials

Controller: Die-cast aluminum

Cable sheathing: Heat-resistant PVC

Connector: Zinc alloy and brass

Cable length 0.5 m

Minimum bending radius 68 mm

Weight Approx. 350 g Approx. 600 g

±0.1% max.

80 mm 120 mm

Distance

120 mm

80 mm

Z510-SW17

Digital output

F502-EN2-04.book Seite 55 Dienstag, 26. Juli 2005 5:48 17