1 D6F-series MEMS Flaw Sensor User’s Manual (A286)

INDEX

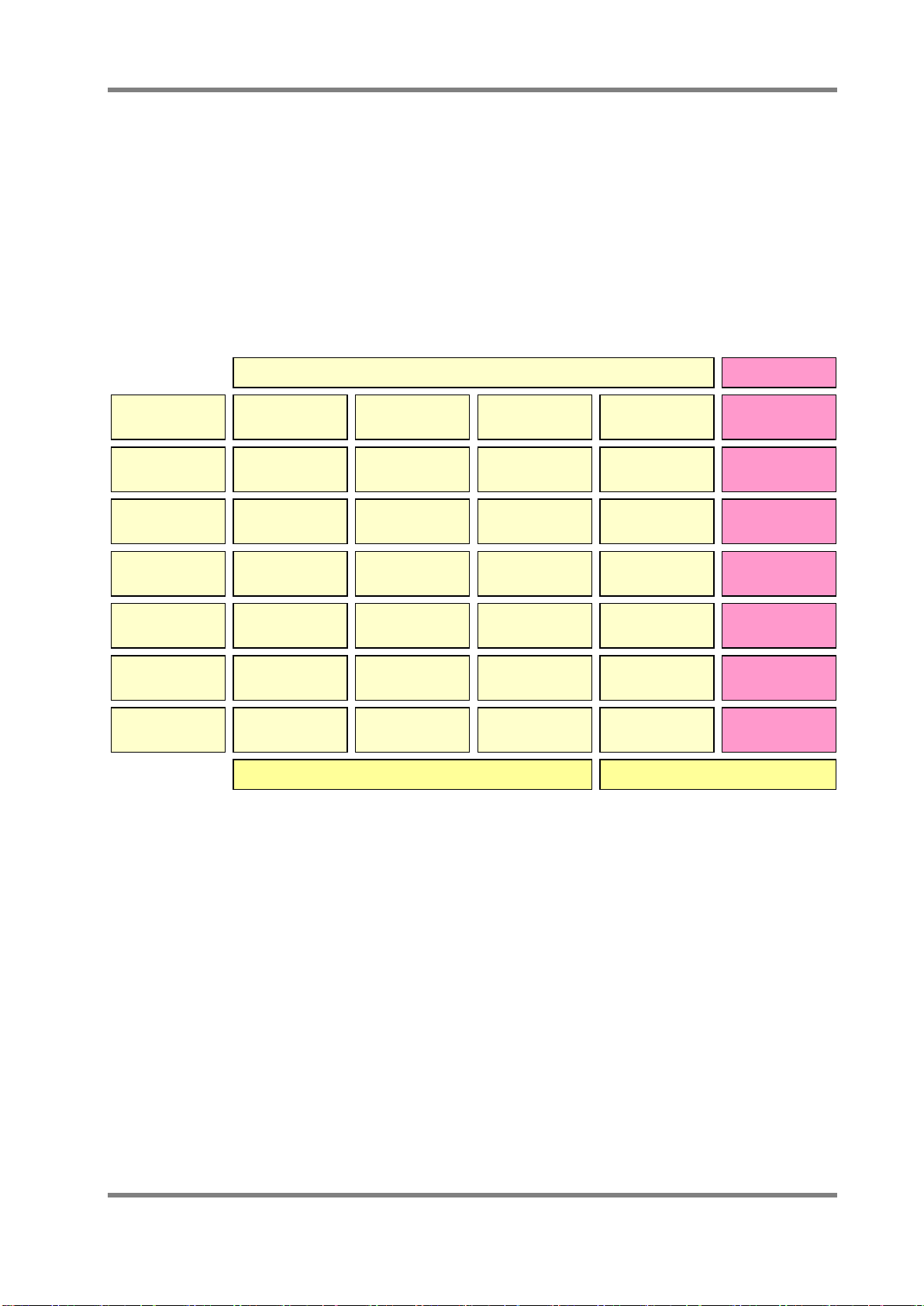

1OUTLINE........................................................................................................................................ 2

2WHAT IS A FLOW SENSOR?....................................................................................................... 2

3STRUCTURE ................................................................................................................................. 2

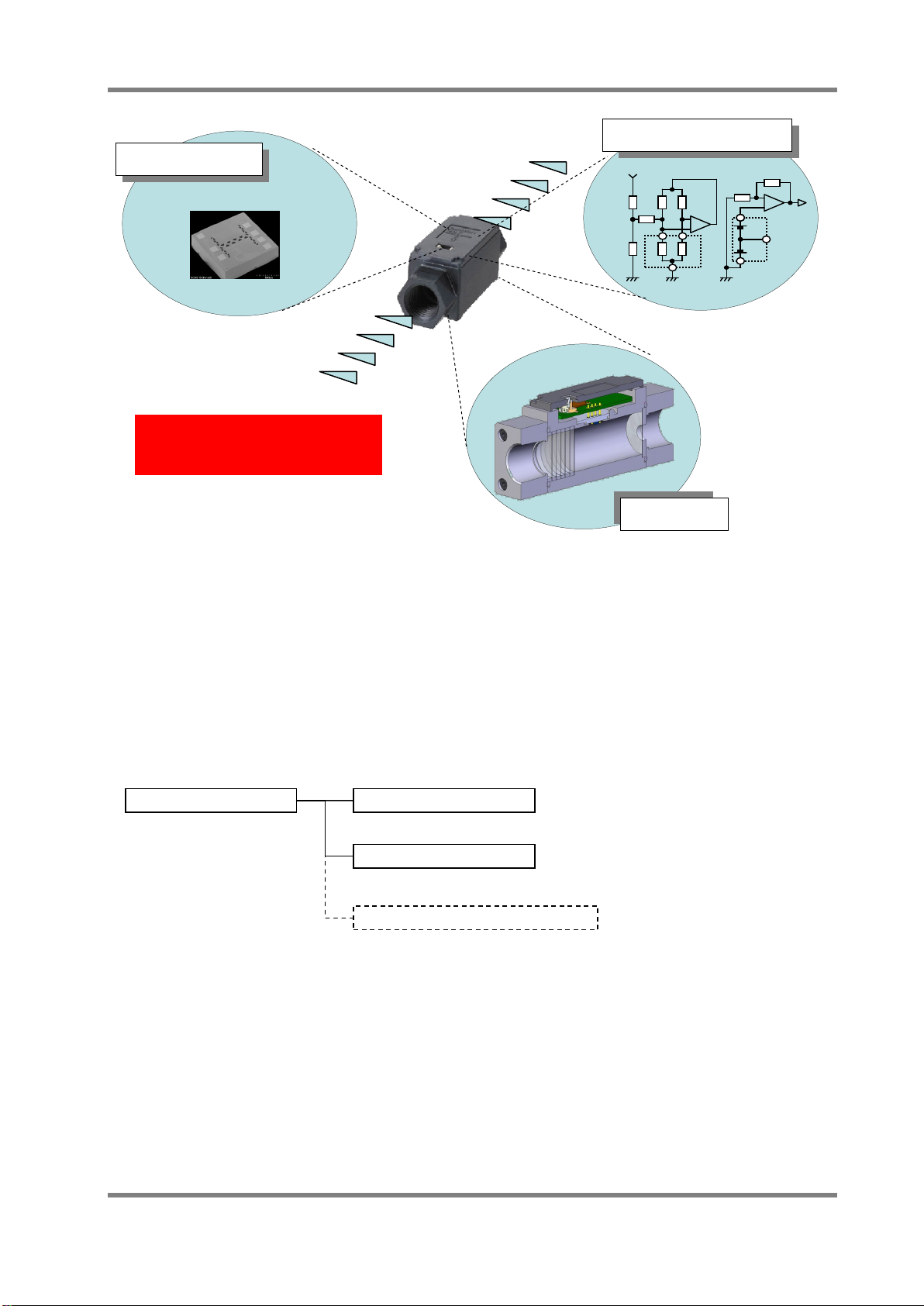

3.1 BASIC COMPOSITION OF FLOW SENSORS.................................................................................... 2

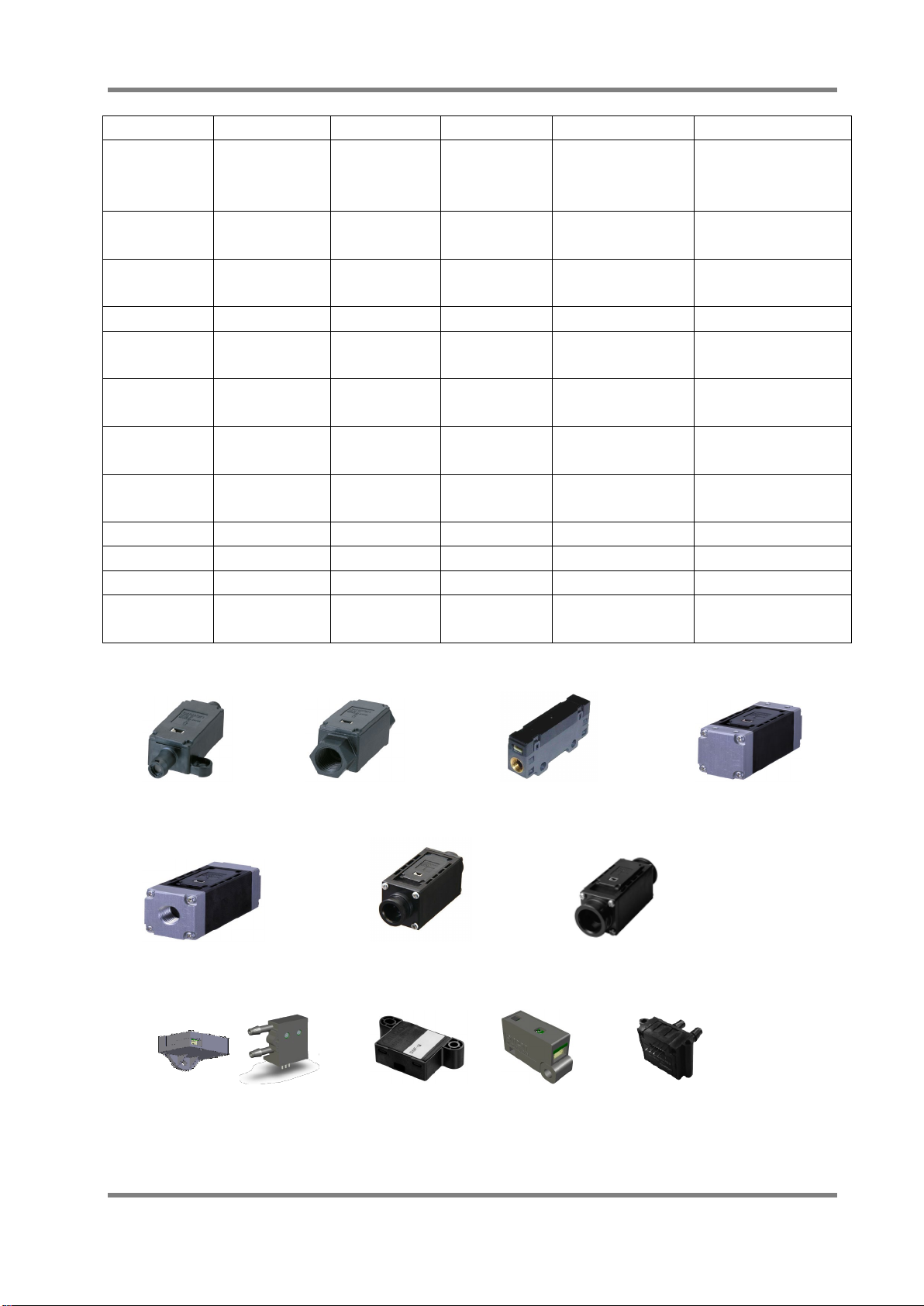

3.2 FLOW SENSOR PRODUCT LINEUP .............................................................................................. 3

4OPERATING PRINCIPLE.............................................................................................................. 4

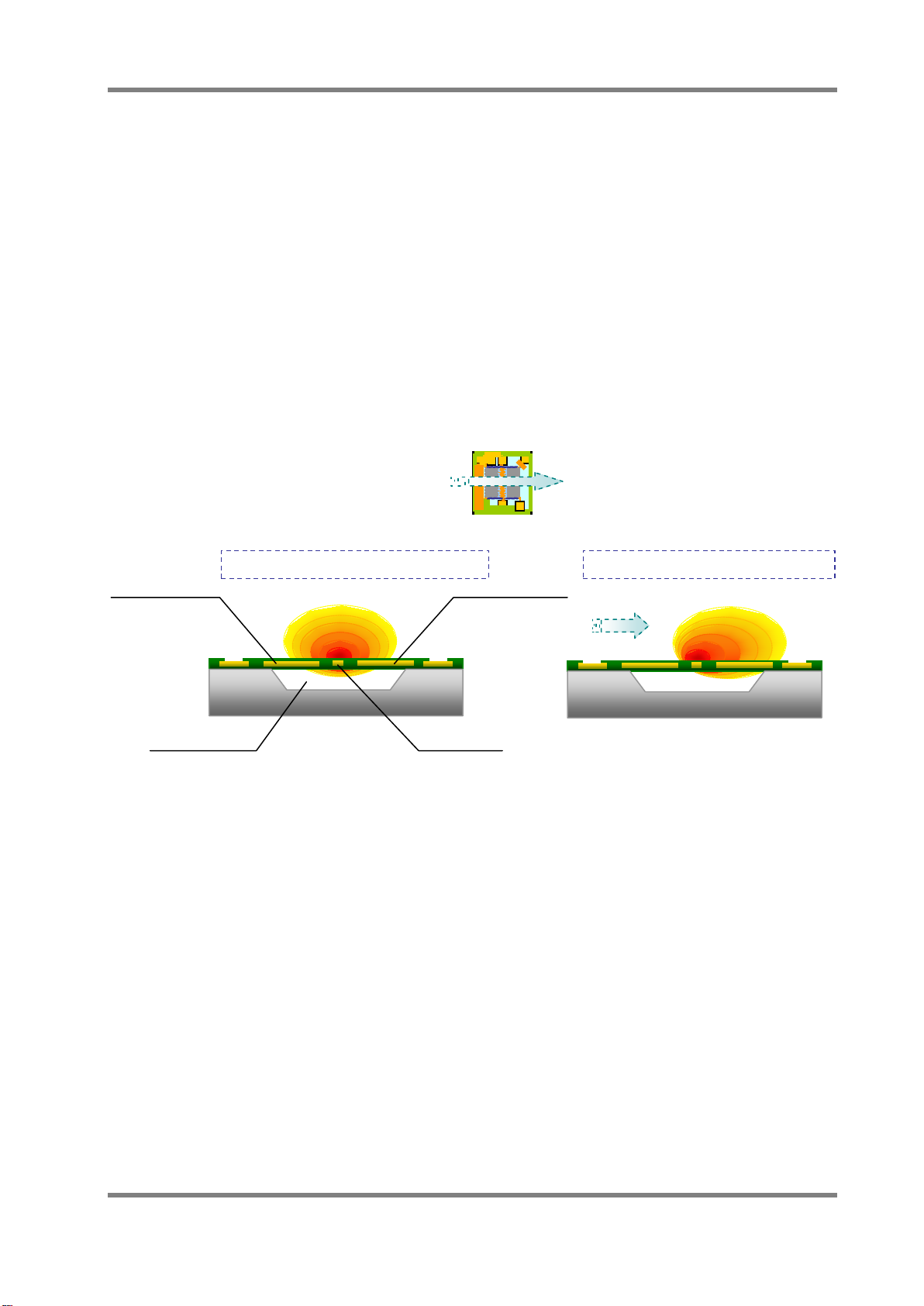

4.1 BASIC STRUCTURE OF MEMS FLOW SENSOR CHIP..................................................................... 4

4.2 DETECTING PRINCIPLE OF MASS FLOW SENSOR.......................................................................... 6

5PRODUCT FEATURES ................................................................................................................. 7

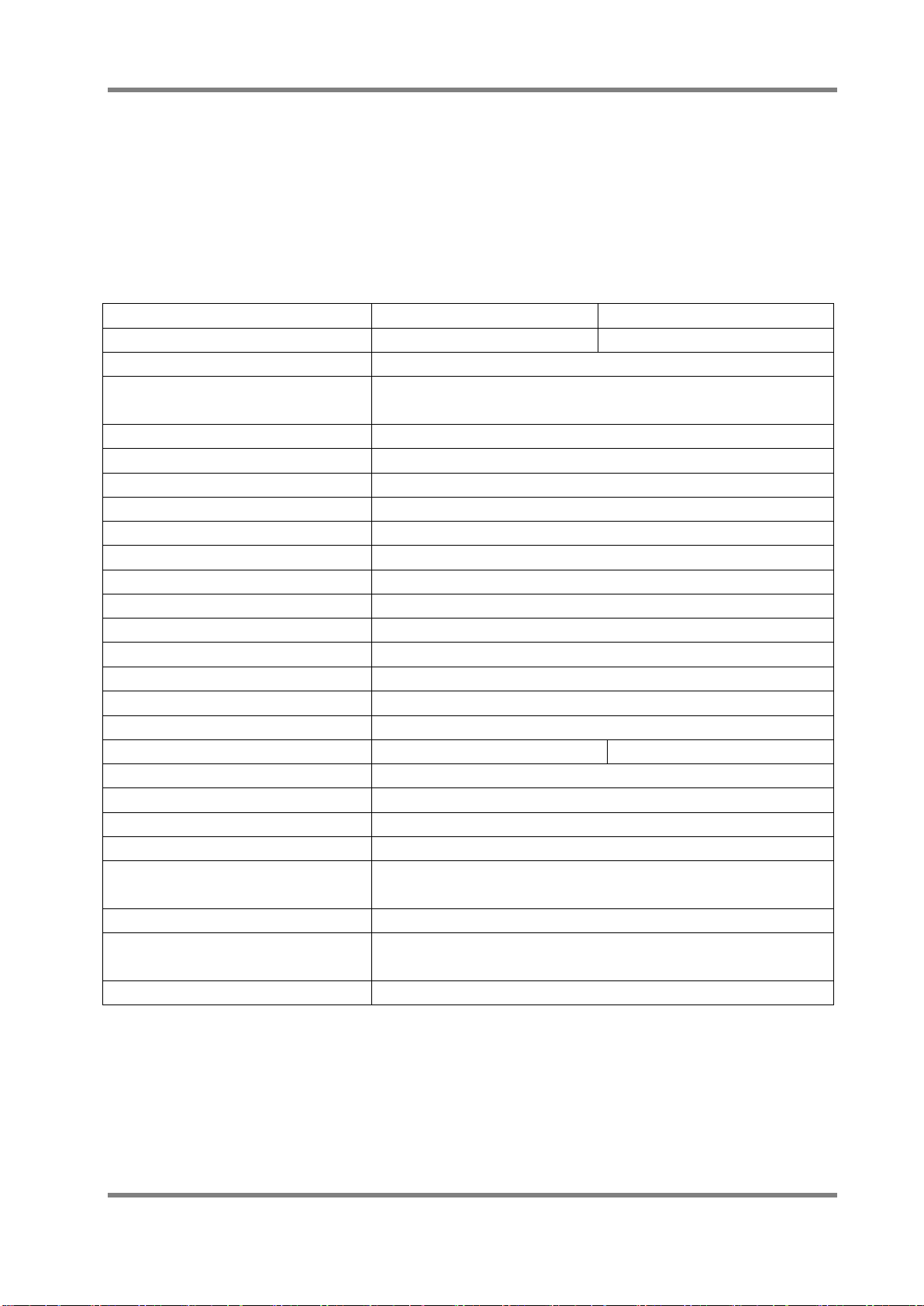

5.1 CHARACTERISTICS OF FLOW SENSORS ...................................................................................... 7

5.1.1 Detection range of flow sensors...................................................................................... 8

5.1.2 Output signal (operating characteristics)......................................................................... 8

5.1.3 Permission pressure performance .................................................................................. 9

5.1.4 Repeatability.................................................................................................................... 9

6USAGE OF FLOW SENSOR ........................................................................................................ 9

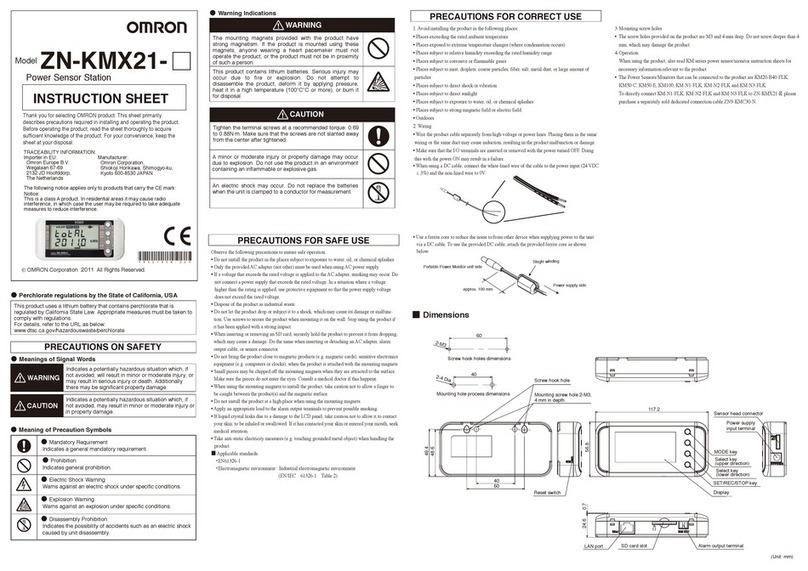

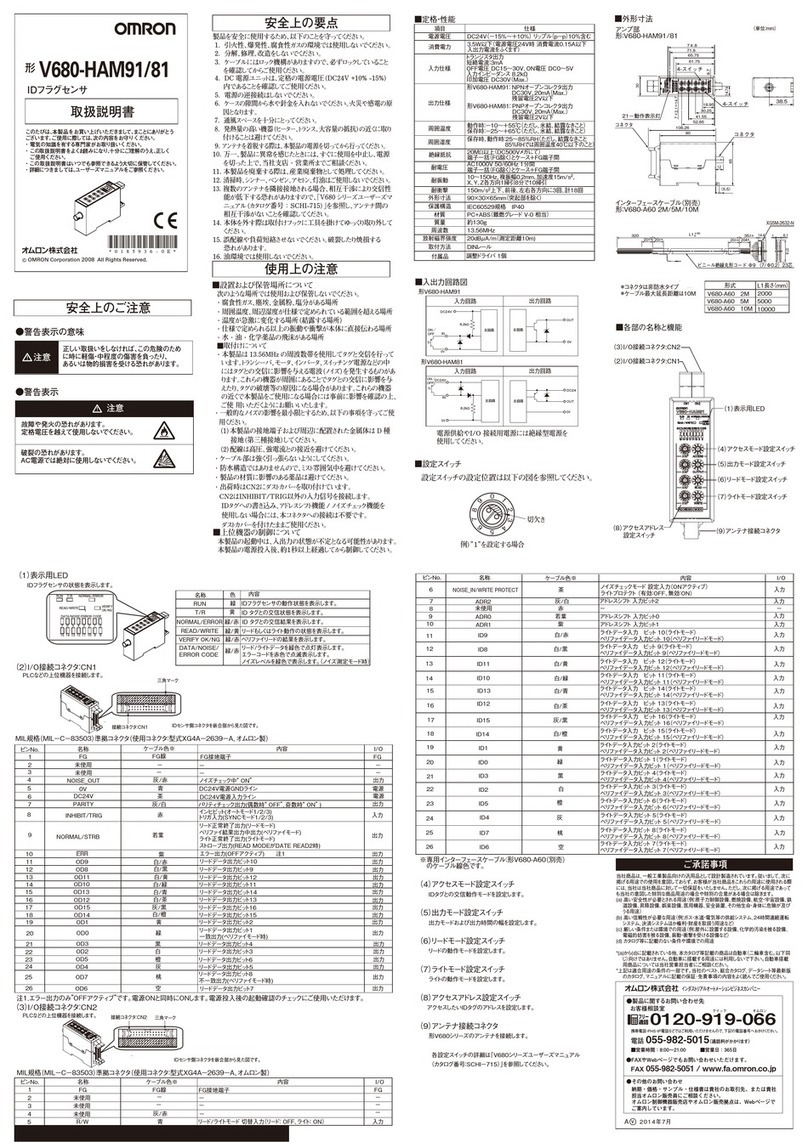

6.1 ELECTRICAL CONNECTION......................................................................................................... 9

6.2 PORT STYLE AND INSTALLATION METHOD.................................................................................. 10

6.2.1 Screw type..................................................................................................................... 10

6.2.2 Quick fastener type........................................................................................................ 10

6.2.3 Manifold mount type .......................................................................................................11

6.2.4 Bamboo type.................................................................................................................. 12

6.3 ATTENTION FOR PIPING AND CONNECTION ................................................................................ 13

6.3.1 Cleanup of the inflow gas .............................................................................................. 13

6.3.2 Stabilization.................................................................................................................... 13

6.3.3 Measurement of high flow ............................................................................................. 13

6.3.4 Consideration of the laminar flow.................................................................................. 14

6.4 THE INFLUENCE OF ENVIRONMENT ........................................................................................... 14

6.4.1 Temperature characteristics .......................................................................................... 15

6.4.2 The influence of dust ..................................................................................................... 15

6.4.3 The influence of pressure and temperature .................................................................. 16

6.4.4 The influence of the mounting direction ........................................................................ 16

6.4.5 Output changes in various gases.................................................................................. 17

6.4.6 The behavior in over flow rate range............................................................................. 17

6.4.7 The influence of humidity .............................................................................................. 17

6.5 APPLICATION EXAMPLE............................................................................................................ 18

7GLOSSARY ................................................................................................................................. 19

8WARRANTY AND LIMITED LIABILITY...................................................................................... 21