Omron ZS Operating manual

Other Omron Accessories manuals

Omron

Omron E3X-N User manual

Omron

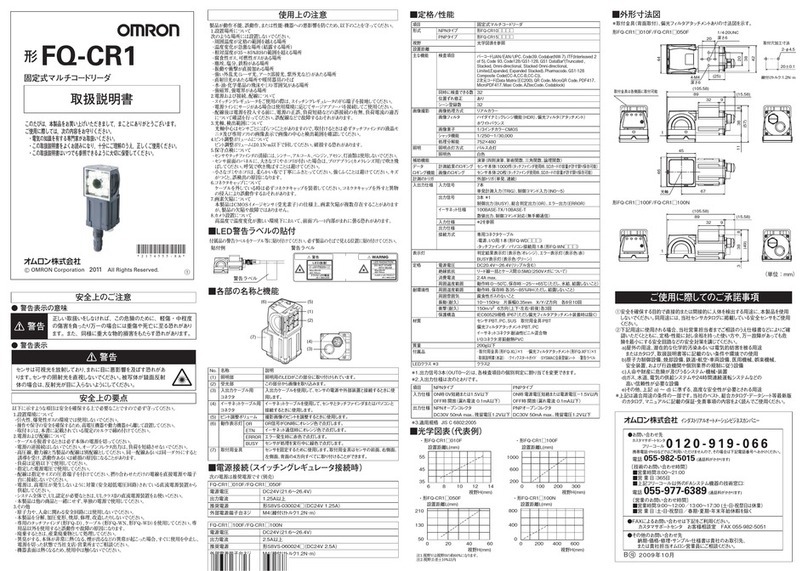

Omron FQ-CR10 Series User manual

Omron

Omron TL-N Series User manual

Omron

Omron F3ET2 Series User manual

Omron

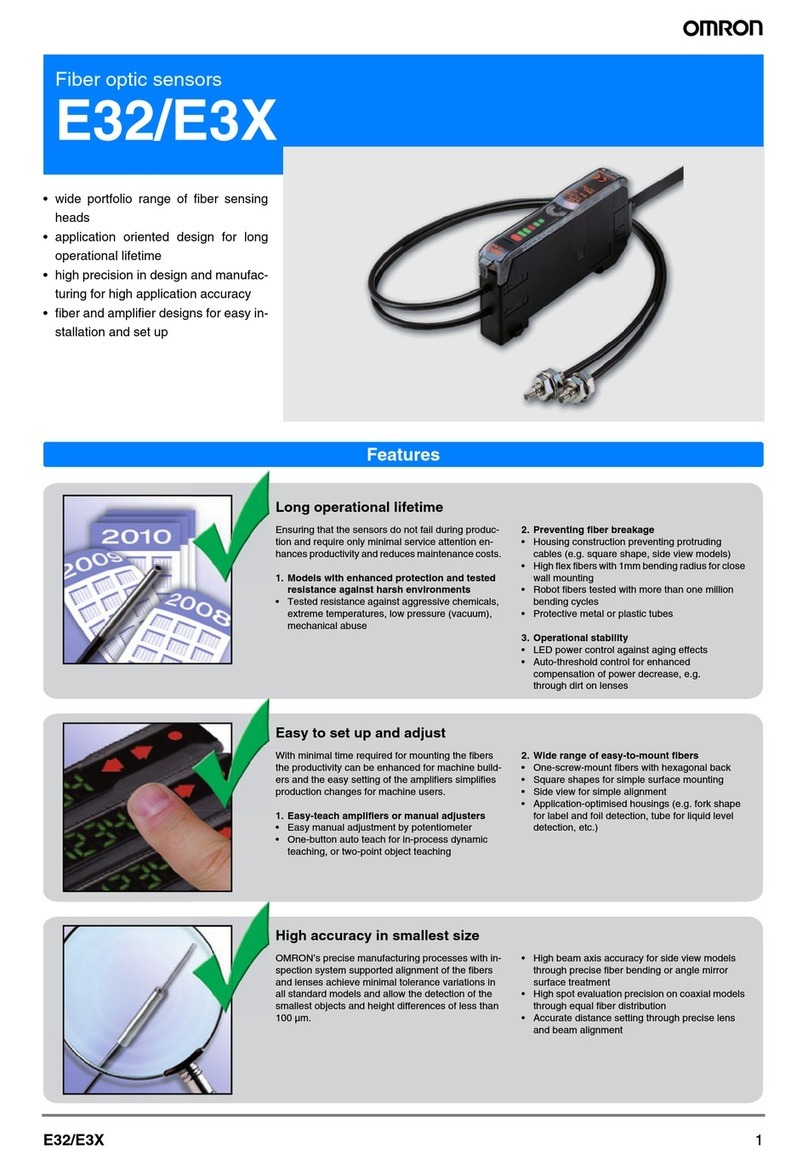

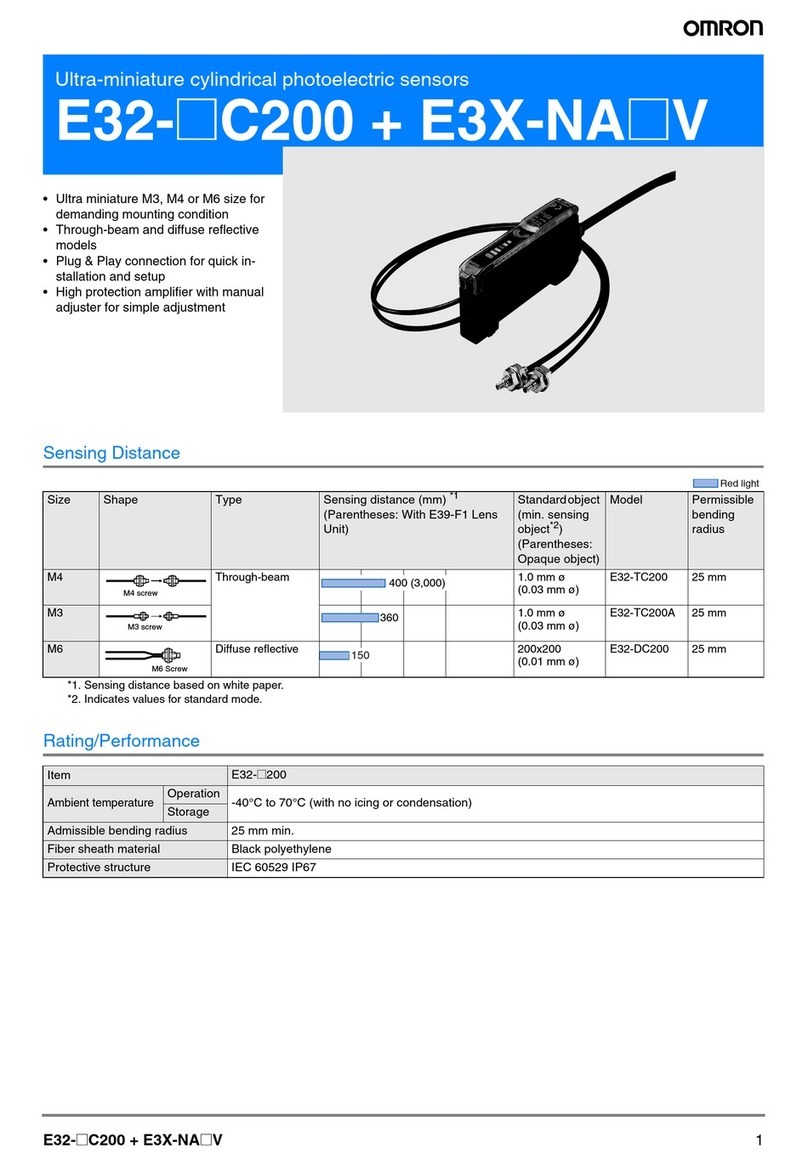

Omron E32 - User manual

Omron

Omron ZX Series User manual

Omron

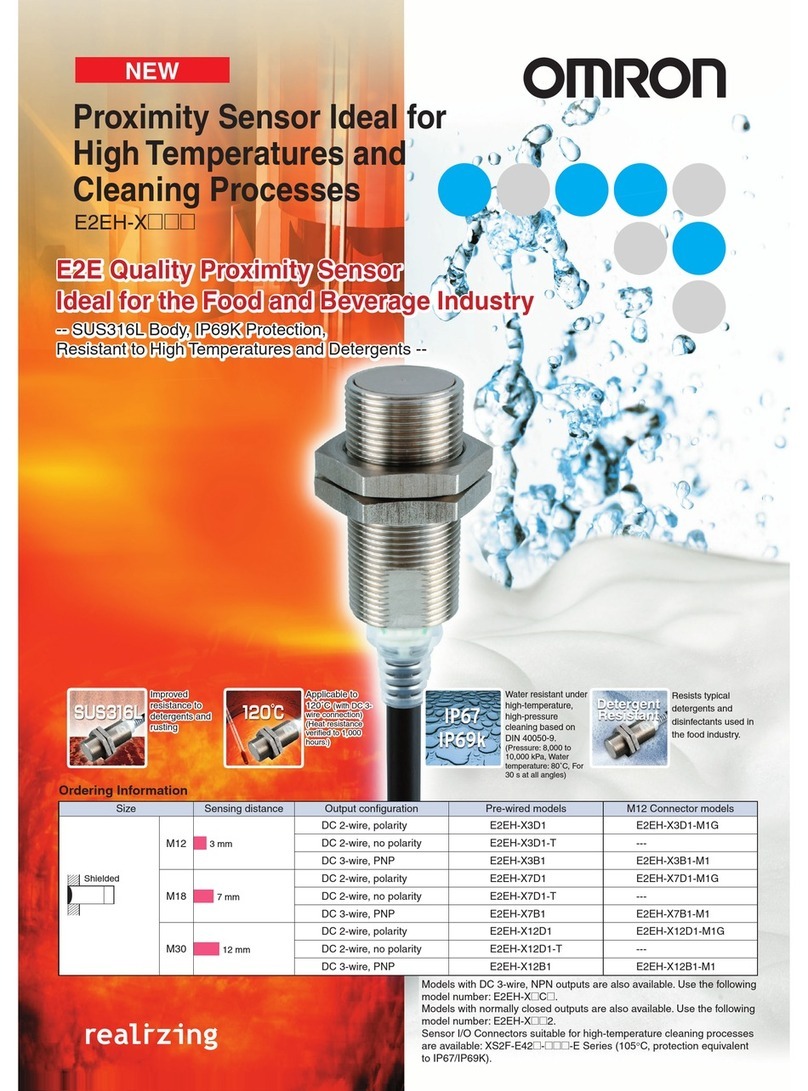

Omron E2EH-X Series User manual

Omron

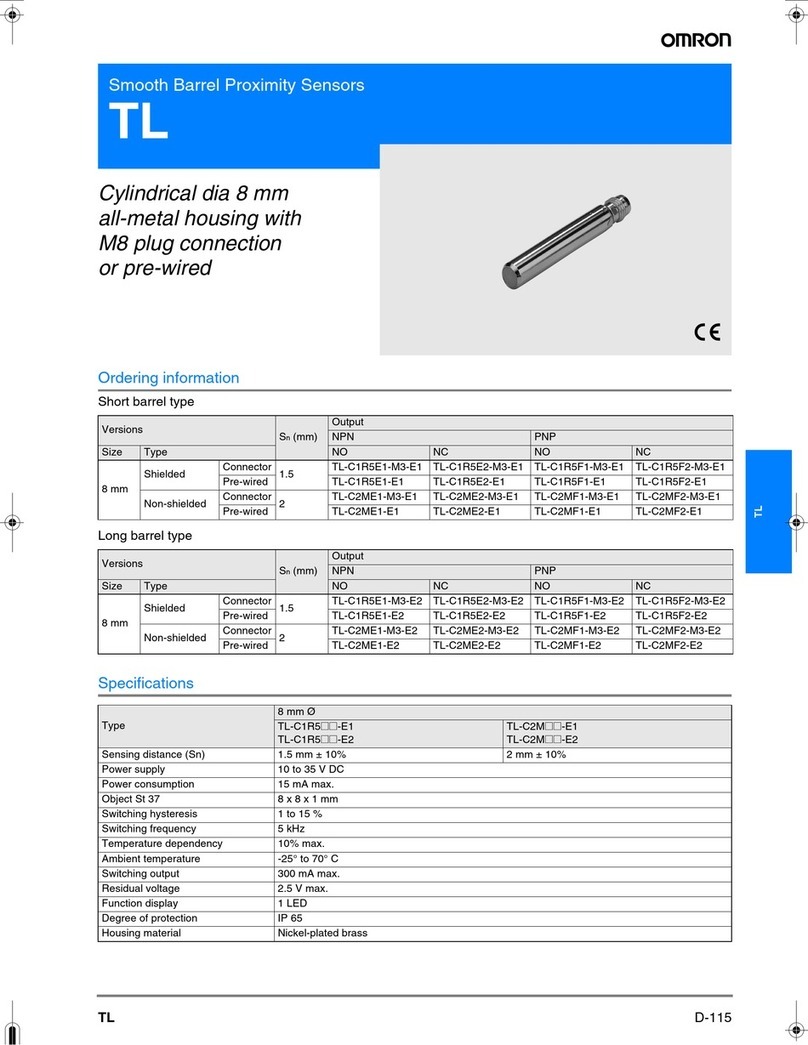

Omron TL User manual

Omron

Omron MX2 COMPONET OPTION BOARD User manual

Omron

Omron E3NW-ECT User manual

Omron

Omron ZW-C1*T User manual

Omron

Omron E2C-EDA Series User manual

Omron

Omron F3W-D User manual

Omron

Omron ZFV Series User manual

Omron

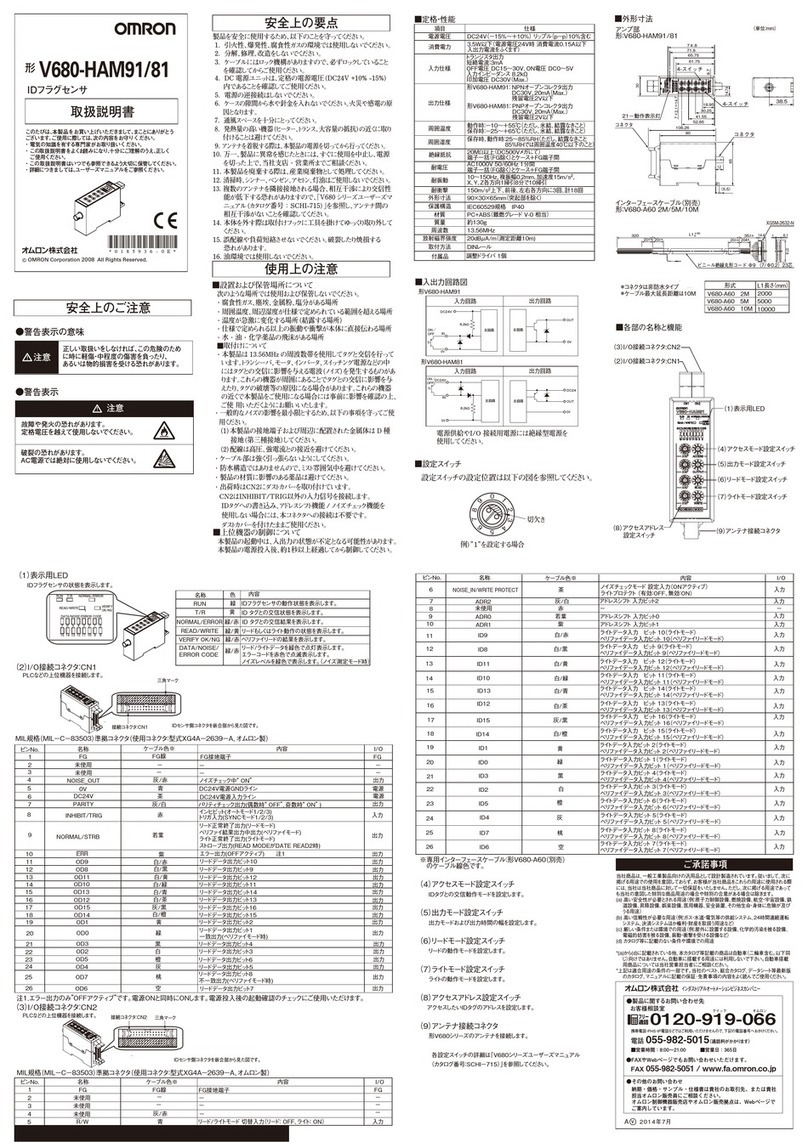

Omron V680-HAM91 User manual

Omron

Omron FZ3 Series User manual

Omron

Omron E3X-NA - User manual

Omron

Omron D6T Series User manual

Omron

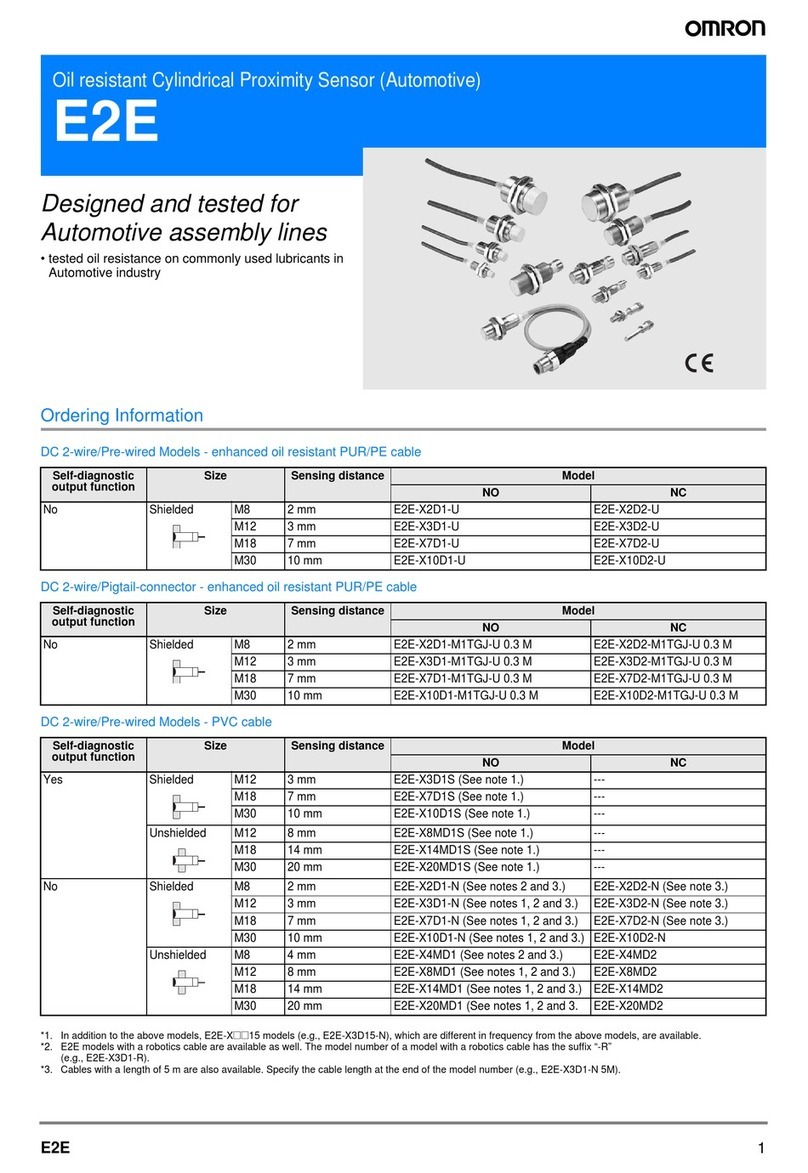

Omron E2E - 2 User manual

Omron

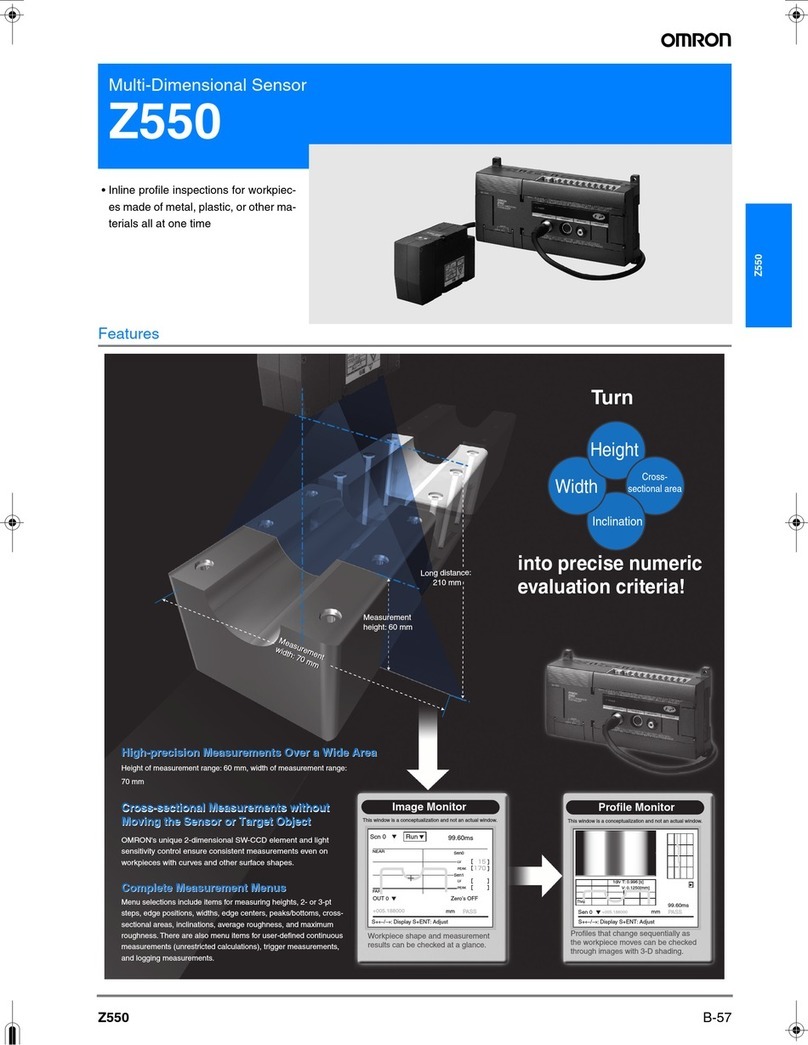

Omron Z550 User manual