D6FZ

8

Air Flow Station

*1. Up to 8 Sensors can be connected when the recording cycle is 2 seconds or longer; up to 4 Sensors can be connected when the recording

cycle is 1 second.

*2. Data is automatically written to the SD memory card when the internal memory reaches its capacity and recording continues until the SD

memory card capacity is reached. Recording stops if there is no SD memory card inserted, when the internal memory capacity is reached, or

when the SD memory card is write protected. (Recording can be resumed after inserting an SD memory card and outputting the data to it by

pressing a button.) The default is Continue Mode. Use the PC Software to change the recording mode.

*3. Recording of the latest measured values continues until the internal memory reaches its capacity. (If the internal memory capacity is exceeded,

data is overwritten from the oldest data in the memory.)

*4. An alarm is output when the upper or lower limit of the air flow that was set in threshold setting mode is exceeded.

*5. You can temporarily read and write data with an SD card that complies with SD/SDHC card standards and was made by another company,

but the SD card may suddenly not be recognized, preventing you from accessing the data.

*6. When mounting the Sensor with magnets, be sure to install it in a location where it will not be subjected to shock.

*7. A T-branch connector to connect to D6FZ-FC02.

*8. OMRON's XW4B-02B1-H1 Connector.

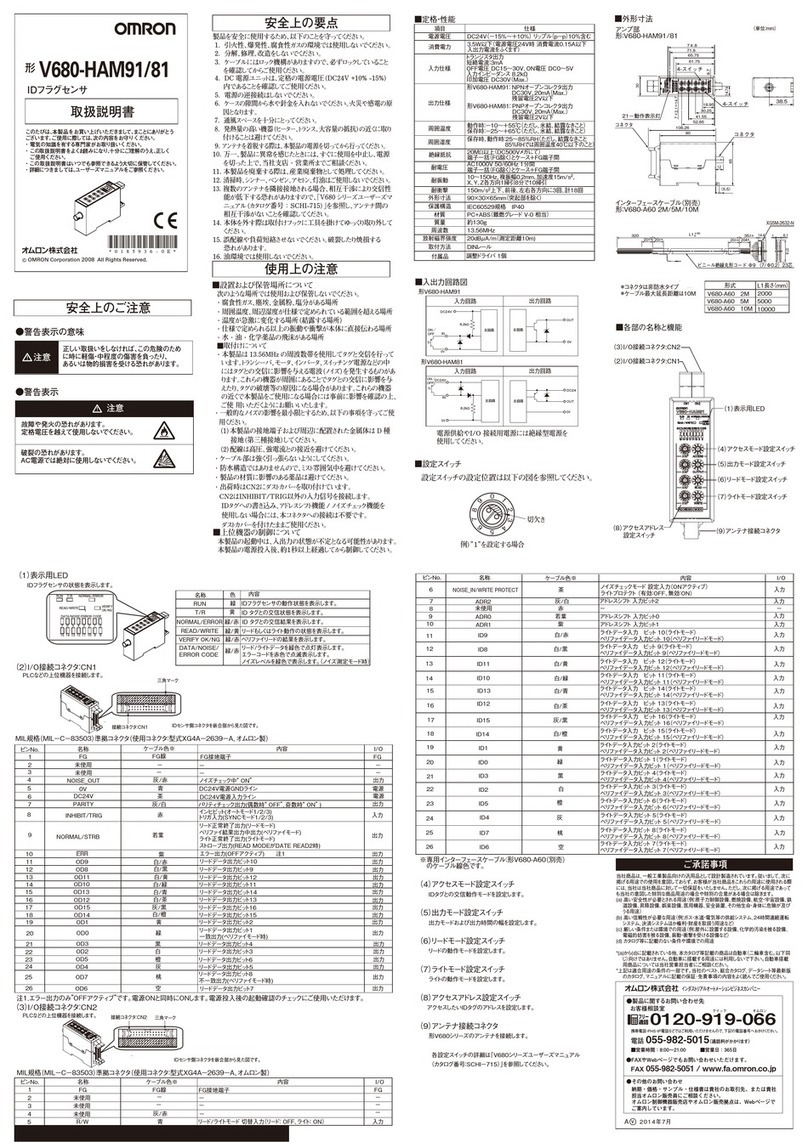

ItemModel D6FZ-FGX21

Connectable Sensors D6FZ-FGT200, D6FZ-FGT500, and D6FZ-FGS1000

Maximum number of connected Sensors 8*1

Indications 7-segment 5-digit 2-row LCD, auxiliary information indicators

Recording interval 1 s, 2 s, 5 s, 10 s, 20 s, 30 s, or 1 min

Displayed data Momentary flow rate, total flow rate, pressure, temperature, and billing amount/CO2conversion

Recorded data Momentary flow rate, total flow rate, volume flow rate, pressure, and temperature

Calculation functions Conversion of total flow rate to billing amount/CO2

Recording modes Continue Mode*2and Ring Mode*3

External output Alarm output (photocoupler output)*4

Communications interface Ethernet (10Base-T or 100Base-TX)

Internal storage device Internal memory: Approx. 4,200 data items when 1 Sensor is connected, Approx. 650 data items

when 8 Sensors are connected.

External storage device SD card (to save measured values and to save/read set values), Recommended SD card: HMC-

SD291 (manufactured by OMRON)*5

Power supply voltage DC input: 24 VDC ±10%, ripple (p-p): 10% max.

Current consumption 80 mA max.

Operating temperature Without Ethernet: −10 to 40°C (with no condensation or icing), with Ethernet: 0 to 40°C (with no

condensation or icing)

Operating humidity 35% to 85% RH (with no condensation or icing)

Storage humidity/temperature −15 to 60°C, 20% to 85% RH (with no condensation or icing)

Insulation resistance 20 MΩ(at 500 VDC)

Withstand voltage 1,000 VAC, 50/60 Hz for 1 min

Vibration resistance (destruction) 10 to 150 Hz with a 0.7-mm double amplitude or acceleration of 50 m/s2for 80 min each in X, Y,

and Z directions

Shock resistance (destruction) 150 m/s23 times each in six directions (up/down, left/right, forward/backward)*6

Material ABS

Degree of protection IP30

Mounting method Magnet mounting, screw mounting, or hooks

Dimensions 117.2 × 24.6 × 56.8 mm (W×D×H) (excluding protruding parts)

Weight (in package) Approx. 150 g (Approx. 500 g)

Accessories Instruction Sheet, Startup Guide, Connection Cable,*7Alarm Output Connector*8