1

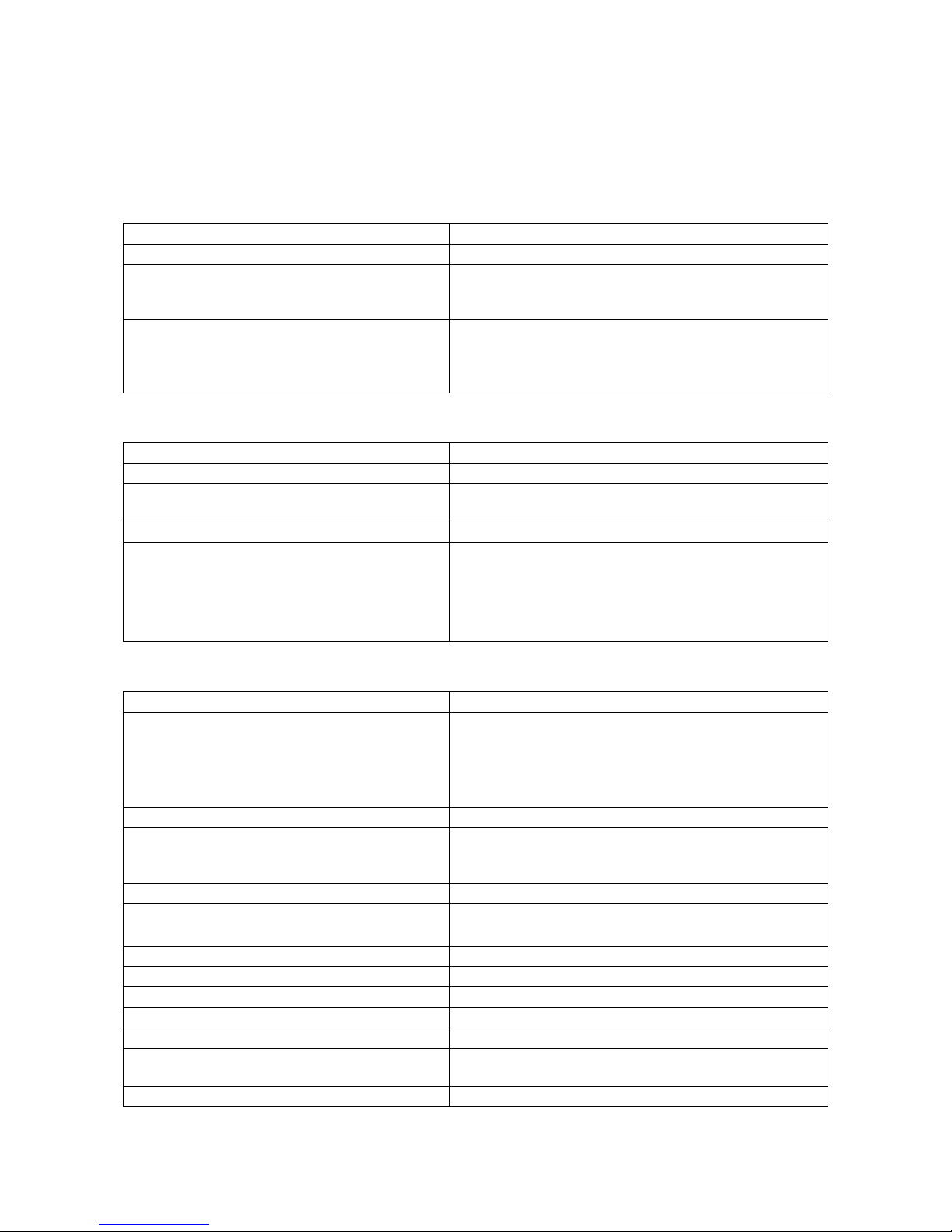

Table of Contents

SECTION 1: Important Precautions . . . . . . . . . . . . . . . . . . . . . 3

1-1 Using the operating instructions . . . . . . . . . . . . . . . . . . . . . .3

1-2 Use in accordance with the intended purpose . . . . . . . . . . . . . . . .3

1-3 Use that is not in accordance with the intended purpose . . . . . . . . . . . . 3

1-4 Warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . .3

1-5 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1-6 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION 2: Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SECTION 3: Specification. . . . . . . . . . . . . . . . . . . . . . . . . 7

3-1 Specifications of Retro-reflective sensor E3NT-R__7 . . . . . . . . . . . . . .7

3-1-1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-1-2 Optical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-1-3 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-1-4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3-2 Specifications of Optical data link E3NT-AL232 (order separately) . . . . . . . .8

3-3 Specifications of Laser alignment aid E3NT-AP1(order separately) . . . . . . . .9

3-4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3-4-1 Sensor E3NT-R17 and E3NT-RH17 (with horizontal connector) . . . . . . . . . . 9

3-4-2 Sensor E3NT-R37 and E3NT-RH37 (with vertical connector) . . . . . . . . . . 10

3-4-3 Universal mounting bracket E39-EL1 (order separately) . . . . . . . . . . . . 10

3-4-4 Adapter bracket E39-EL2 (order separately) . . . . . . . . . . . . . . . . 11

3-4-5 Optical data link E3NT-AL232 2m (order separately) . . . . . . . . . . . . . 11

3-4-6 Alignment bracket E39-EL4 (order separately) . . . . . . . . . . . . . . . . 12

3-4-7 Laser alignment aid E3NT-AP1 (order separately) . . . . . . . . . . . . . . 12

3-4-8 Retroreflectors (order Separately) . . . . . . . . . . . . . . . . . . . . . 13

SECTION 4: Function . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-1 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-2 Display and operator controls . . . . . . . . . . . . . . . . . . . . . . 15

4-2-1 LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-2-2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-2-3 Push buttons on the sensor . . . . . . . . . . . . . . . . . . . . . . . 16

4-2-4 Set-up via a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-3 User set parameters . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-3-1 Output function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-3-2 Output switching . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-3-3 Function of connector pin 2 and 5 . . . . . . . . . . . . . . . . . . . . . 17

4-3-4 Switch-on delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-3-5 Switch-off responses . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-3-6 Timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-3-7 Keyboard lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-3-8 ECO energy saving mode . . . . . . . . . . . . . . . . . . . . . . . . 18

4-3-9 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-4 Inputs/Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-4-1 Input: Test input TEST . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-4-2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 5: Transport . . . . . . . . . . . . . . . . . . . . . . . . . 21

5-1 Packaging / Transportation damage . . . . . . . . . . . . . . . . . . . 21