ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL PORTUGUÊS

EN-7

Warning

Do not exceed the voltage or current rating

specified for any of the terminals during installation,

doing so might cause fire or damage to the devices.

[AX-70/130/200TN]

[AX-100/200TF]

N.C. / N.O. selection Swich

N.C. N.O.

3

OFF ON

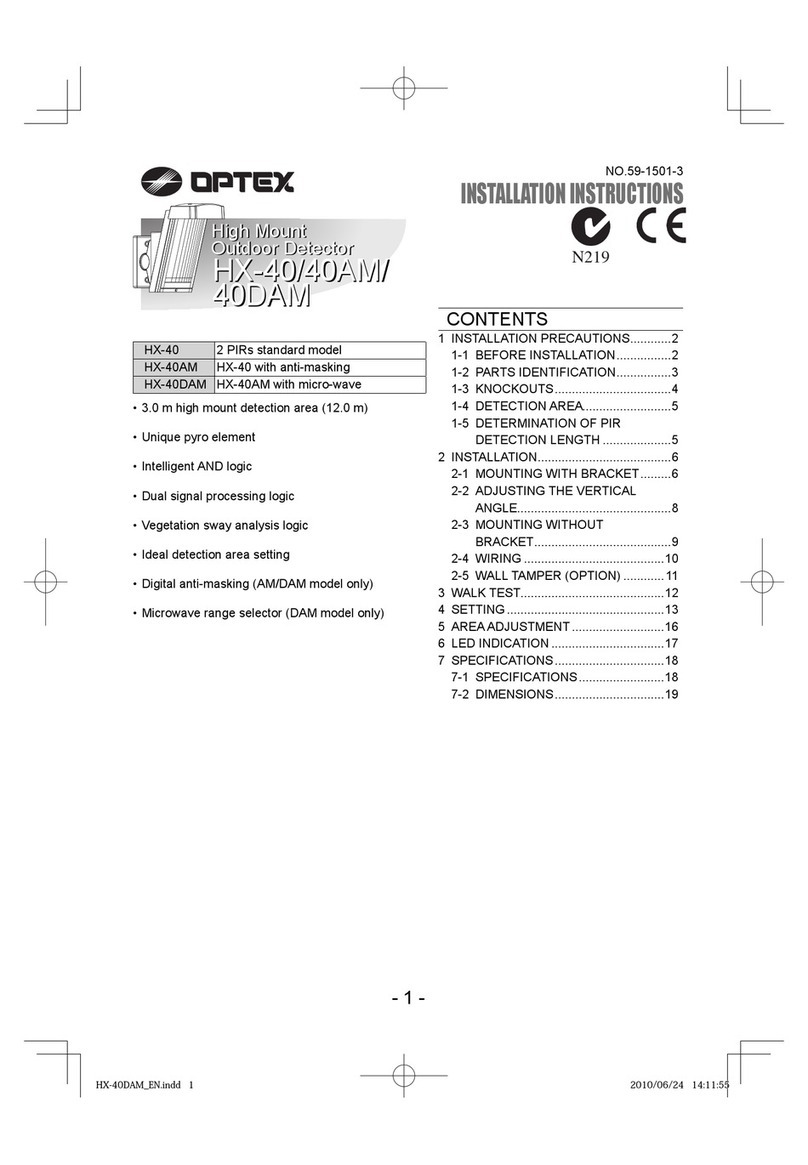

4WIRE CONNECTION

Connect respective wires to the terminals shown in the following figure.

• Ensure that the wiring distance from the power supply is within the range shown in the table on the below.

• When using two or more units on one wire, the maximum length is obtained by dividing the wire length listed

below by the number of units used.

For UL Listed applications, the units shall be connected

to a UL Listed control unit or Listed Burglar Power

Supply capable of providing a minimum of 4 hours

standby power.

-Terminal

-Wiring distance between power supply and detector

Non-Voltage contact output

Resistive load only

Note>>

Note>>

Alarm output (N.C.)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

< Receiver >

< Receiver >

Tamper output

(It opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.1A (max.)

Power input

10.5 to 28VDC

Power input

10.5 to 28VDC

Power input

10.5 to 28VDC

Power input

10.5 to 28VDC

Tamper output : (BE) Model only

(it opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.1A (max.)

< Transmitter >

< Transmitter >

Alarm output: (N.C./N.O.) switch (In case of using N.O., contact is

not reversed when power supply is off.)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

Tamper output

(It opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.1A (max.)

Use the COM. terminal for both alarm

output and D.Q. circuit.

Environmental Disqualification (N.C.)

Non-Voltage contact output

Contact capacity : 28VDC and 0.2A (max.)

Tamper output : (BE) Model only

(it opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.1A (max.)

AWG22

(0.33mm2)

Wire size

AWG20

(0.52mm2)

AWG18

(0.83mm2)

AWG16

(1.31mm2)

500 m (1700 ft.)

700 m (2200 ft.)

1100 m (3600 ft.)

1700 m (5500 ft.)

2400 m (7800 ft.)

12VDC 24 VDC

Power supply voltage

3500 m(11400 ft.)

5500 m (18000 ft.)

8000 m (26200 ft.)

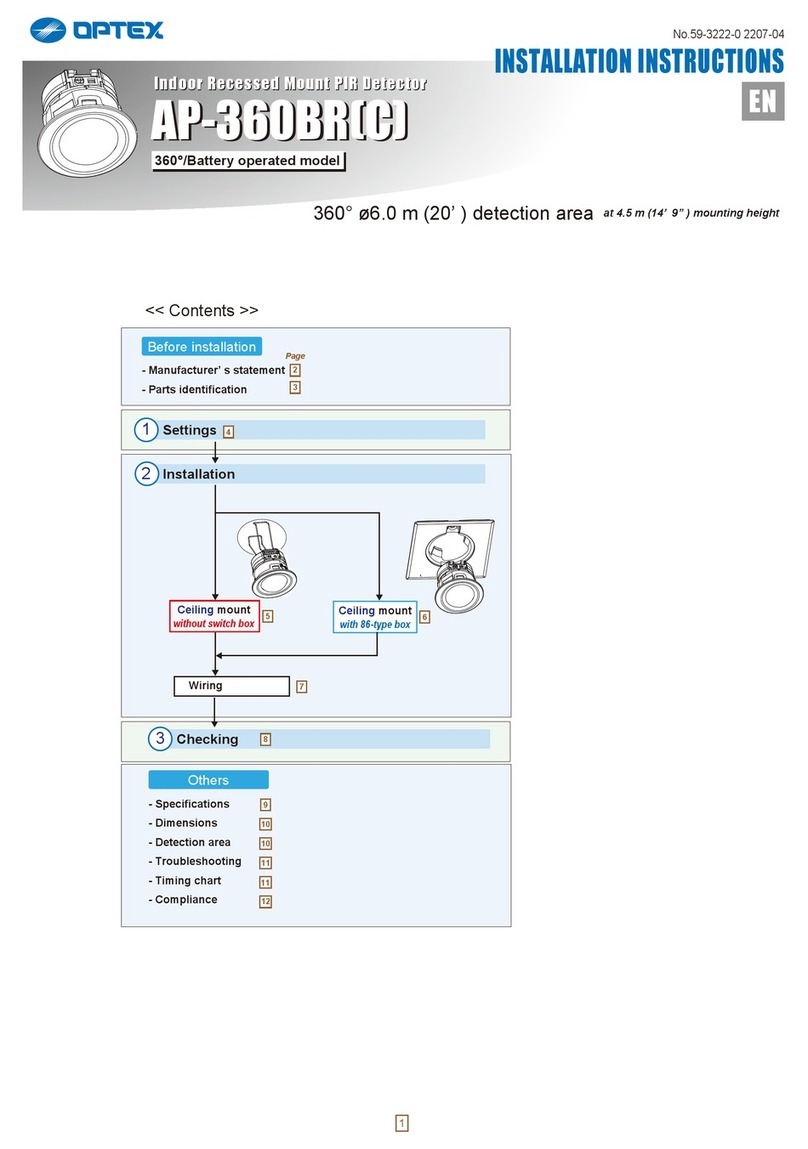

5ALIGNMENT

The optical alignment is an important adjustment to increase reliability. In accordance with the procedure indicated

in the items 1. and 2. in this chapter, make sure to align the monitor jack that monitor output nothing to attain the

maximum level.

• While looking through the viewfinder, turn the dial to make alignment in such a way that the other detector is

at the center of the sights.

• After the rough alignment using the

viewfinder, check the light receiving

status by the Alarm Indicator.

When making the adjustment by the monitor jack, be

careful not to intercept the optical unit with your hand,

the tester pin cord, etc.

Note>>

< Horizontal alignment > < Vertical alignment >

< Receiver / Transmitter >

Checking of the illumination of the Alarm Indicator

• After checking the receiving level of optical axis by using the alarm indicator, make sure to make fine alignment for

both transmitter and receiver with voltmeter until it reaches maximum monitor output over “Good” level.

Fine adjustment with monitor jack

< Receiver >

< Receiver >

Alarm Indicator

View Finder

• For Horizontal/Vertical alignment, refer to the following

illustration.

AX-100/200TF

Alarm

Indicator

Light

interrupting Light receiving

ON(red) fast

flicker slow

flicker OFF

Monitor

output

Realign

Less than 1.0V

Fair

1.0V

or more

Good

2.0V

or more

Excellent

2.5V

or more

AX-70/130/200TN

Alarm

Indicator

Light

interrupting Light receiving

ON(red) OFF

Monitor

output

Realign

Less than 2.2V

Fair

2.2V

or more

Good

2.5V

or more

Excellent

2.9V

or more

The relation between monitor output and receiving level of optical axis.

5-1

OPTICAL ALIGNMENT

1Rough alignment by viewfinder

2Checking of the illumination and Fine alignment

Turn the horizontal alignment

dial by fi ngers to make

alignment

Set the voltmeter range to 5 to 10VDC and connect

the voltmeter probes and to and of the

monitor jack respectively.

The horizontal / Vertical alignment.

Turn the vertical alignment

dial with a screwdriver to

make alignment

The alignment

can be completed. Realignment

(example)

The beam is not

properly aiming at the

center of viewfinder.