6

Benet of a Multi-task System

Conventional imaging systems cannot perform two inspection processing simultaneously. With Dual Mega

ARCS Engines, one controller accepts two trigger inputs simultaneously or randomly to process two different

setups parallely or independently.

Complete parallel processing of measurement and logging means you can also connect high-speed, large-

capacity (up to 2 terabytes) hard disk drives. Accordingly, you can save all images on high-speed tact lines,

which was difficult to do with conventional systems (*1).

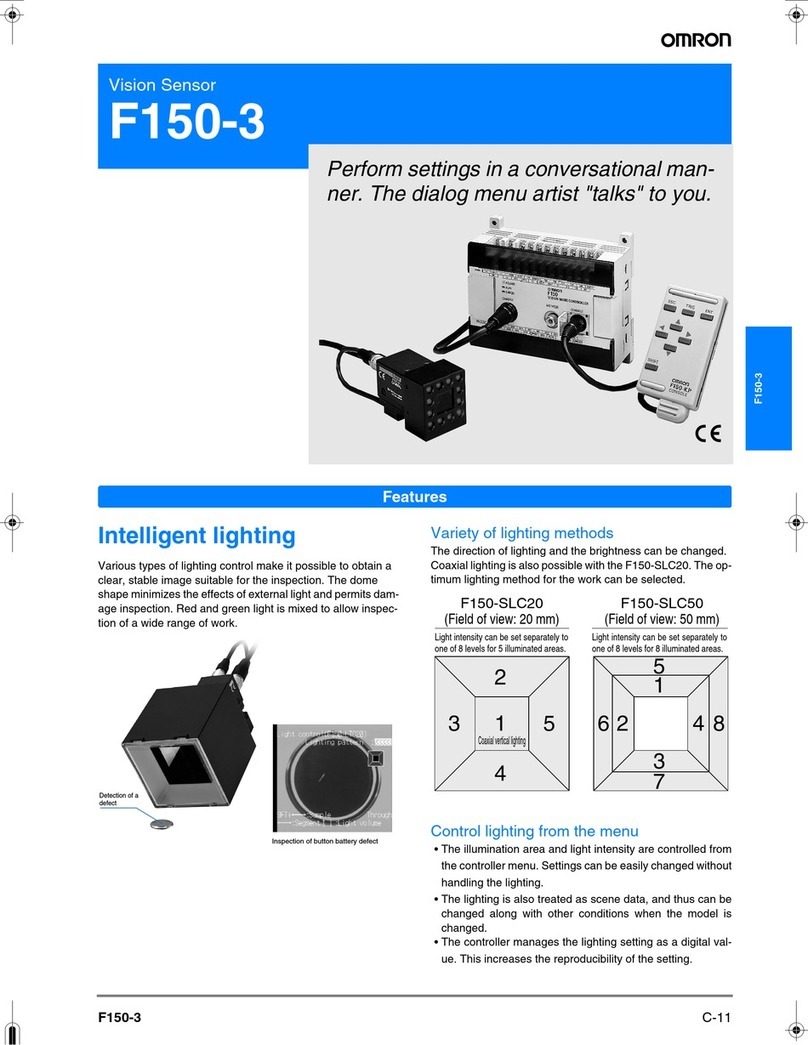

One unit performs inspections that normally require two units Multi-line random trigger mode

All images can be saved even during measurement High speed logging mode

Printing inspection in

automobile assembly

processes

Defect inspection on a new

product or a line adopting a

new manufacturing method

All images you have saved can be utilized for

trend analysis to help establish an appropriate

manufacturing method quickly for a new product

or a line adopting a new manufacturing method.

r

When a NG occurs, the cause can be identified and

remedial actions taken quickly.

r

Saving all images leads to more efficient traceability control.

Before, two controllers were needed to inspect two locations,

processes or lines within the required tact time, which added

to introduction cost.

With the FZ3-900 series, on the other hand, two triggers

can be input randomly to run two independent inspection

processing in parallel.

Since logging was not possible during measurement, the user

had to choose either measurement or logging. Accordingly,

not all images could be saved or image input triggers had to

be delayed depending on the measurement trigger intervals.

Measurement and image logging are processed completely in

parallel. As a result, you can save all images.

Image input 1 Image input 2 Image input 3

Priority on image logging

Priority on measurement processing

Image input

Image input

Image logging

Measurement

processing

Measurement

processing

Image

logging 1

Measurement

processing

Measurement

processing

Interruption

Image input 1 Image input 2 Image input 3

Image input

Measurement

processing

Measurement

processing

Image logging 1 Image logging 2

Measurement

processing

Measurement

processing

The next image input is delayed

Image input 1 Image input 2

Measurement

processing

Image logging 1

All you need

is one unit

[Conventional system]

[High speed logging]

All images are saved.

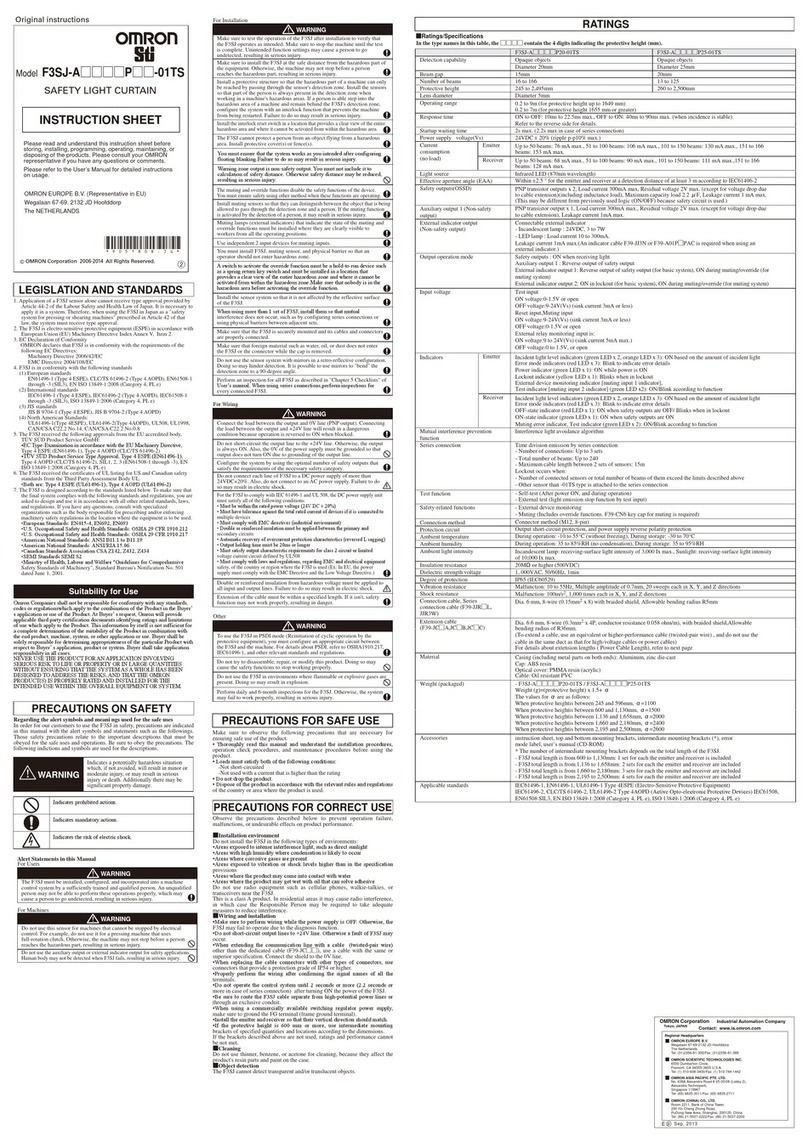

*1 All imagescan be saved under the following conditions:

r300,000-pixel camera x 1 unit . Measurement time: 33 ms

rImagescan be saved continuously for approx. one week when a 2-terabyte

HDD isused (based on 8 hoursof operation a day).

Introduction

cost

Installation

space Halved!

Simultaneous inspection of two

locations

This mode is ideal for applications where triggers

are not input simultaneously or constantly, such

as when the top surface is inspected with a single

trigger and side faces with four triggers.

You can reduce the number of controllers to be installed

to save installation space, introduction cost and current

consumption.

Random inspection of lines

positioned close to each other

Even when the timing of work arrival

is not at constant intervals, they can be

inspected with only one controller.

Effect

Effect

Issues

Resolution

Resolution

Reduce the time and cost for setup and operation

Issues