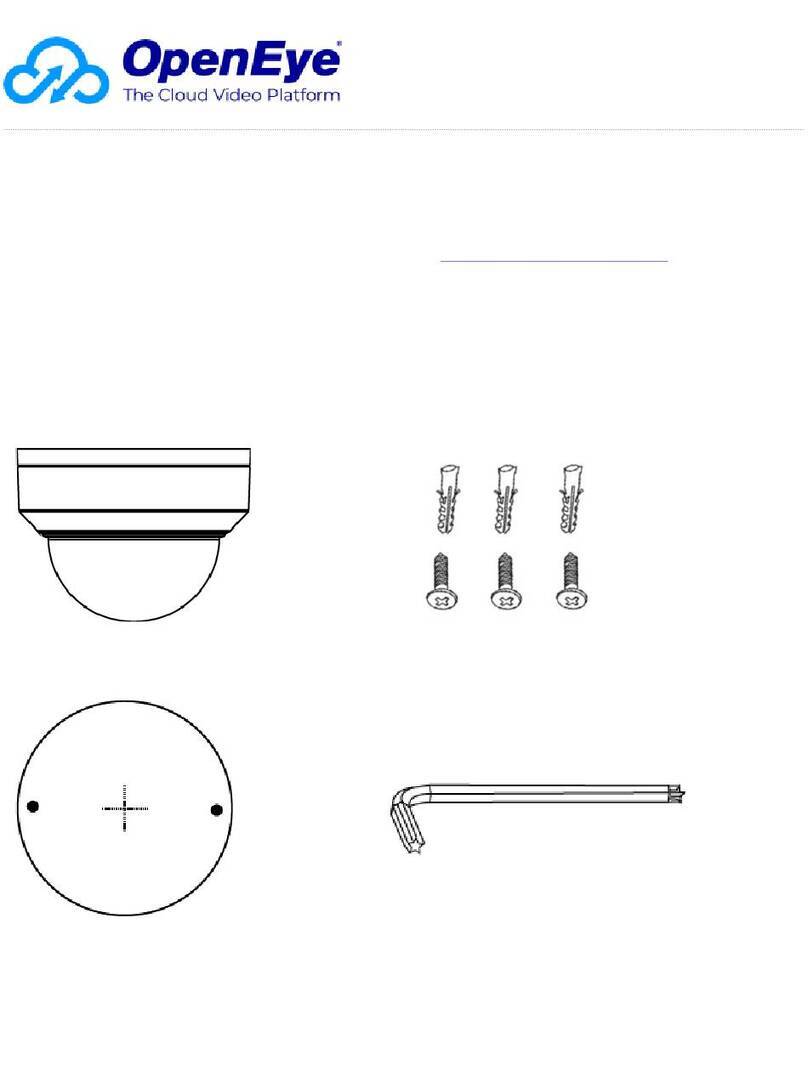

Installing the Dome Enclosure

-7-

1

2

3

4

5

Remove the dome cover

Use the supplied Torx driver to loosen, if required, (but not remove) the four cover

screws. The screws are captive and will be retained in the lid.

Use the template to mark and prepare the mounting area

All mounting access positions are sealed until they are ready to be used. For example

when surface-mounting the housing, first knock-out the screw access holes that

correspond to the template marks “T1”. This can be accomplished by using a Phillips

screwdriver.

Select the desired cable entry

Mount the dome enclosure

Connect the wiring

IMPORTANT: The power supply must be Class 2 certified.

IMPORTANT: If the dome is being mounted externally, use a suitable sealant around

the cable entry hole to ensure a moisture resistant seal.

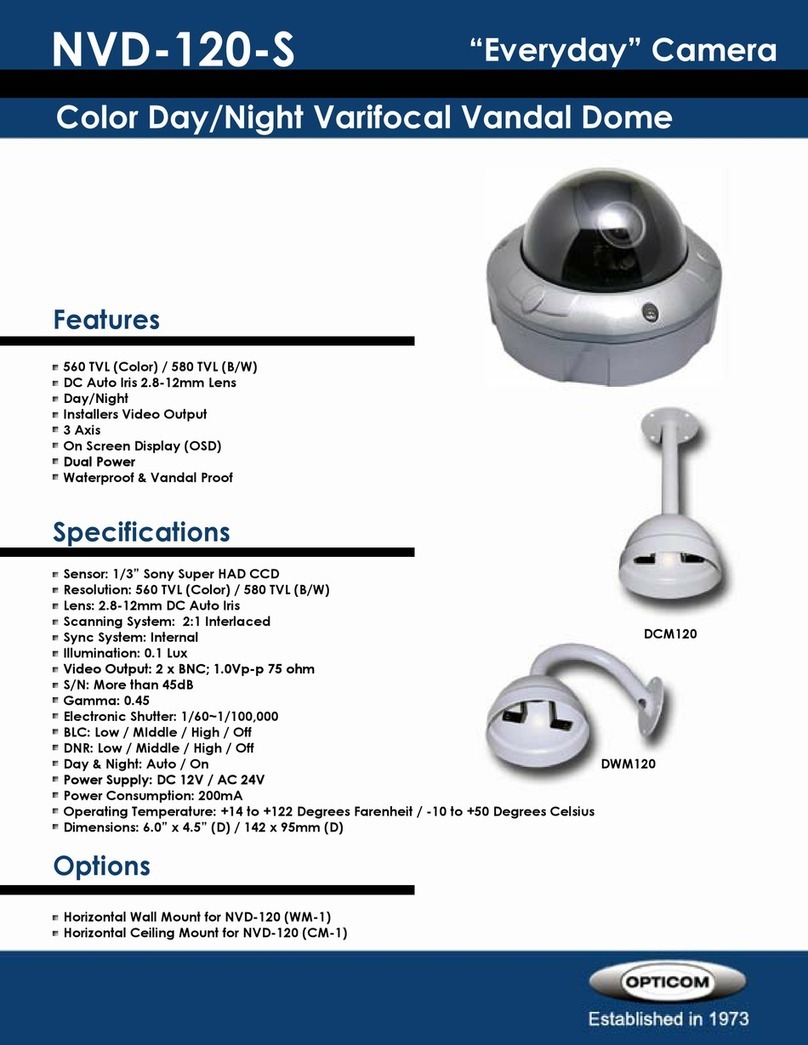

300 Series Color

Camera Connections

Main camera

connection

Programming port for factory used

OSD

connection

Using one of the mounting schemes discussed in this document (Methods for

mounting the enclosure), mount the dome enclosure (and outer ring, if necessary) in

place. When flush or surface mounting using the outer ring, ensure that the large

rubber gasket (D6) is in place under the lip of the dome enclosure.

Note: When using the outer ring, the two internal ribs of the outer ring must fit into the

slots in the sides of the dome enclosure, adjacent to the two locking arms (which must

be retracted).

IMPORTANT: If the dome is being mounted externally using the four base holes, use

the supplied rubber o-rings in each of the four mounting holes of the dome base to

ensure a moisture resistant seal (see fig C).

Feed the preconnected main leads (that terminate at

connections E1 and E2) through the cable access and

connect it to your video out and power in cables. A

wire-ended adapter lead (E7) is supplied for use with

power supply cables that are not terminated with an

appropriate power connector.

For 12VDC operation: Connect the red lead to the

positive supply and the black lead to the negative

supply. For 24VAC connection, polarity is not

important.

Use either the base cable entry (D1) or side cable entry (D3) as necessary. When

surface mounting and using the side cable entry (D3), open either the large (D4) or

small (D5) knock-out within the outer ring to the desired size by cutting away excess

material with a hole cutter, sharp knife, or side cutters. The outer ring can be rotated

so either of the knock-outs align with the side cable entry, as necessary. Unused

cable entries should be secured with sealing plugs (D8).

Note: Route cables through the supplied slotted rubber grommets (D9) to prevent dust

infiltration.